09, 2023

by OREE LASER

How much does a laser cutting machine cost?

The laser cutting machine price depends on different factors: laser source, laser power, work area, cutting material, Software and Control System, Production Quality, etc. However, There are more and more types of laser cutting machines on the market. This article will look at what affects the metal laser cutter price and suggest the best ones for different uses.

Fiber laser cutting machines are better and safer at cutting materials like copper, brass, and aluminum compared to CO2 lasers. This is because the fiber laser beam is easily absorbed by these materials, instead of bouncing off. Moreover, using a fiber laser is more cost-effective. It consumes less electricity and is more efficient, which means it costs about half as much to operate compared to a CO2 laser system.

A powerful fiber laser cutter can cut materials up to 5 times faster than a regular CO2 laser and costs only half as much to operate.

Unlike CO2 lasers, fiber lasers can start instantly without any warm-up time.

Fiber lasers don't require maintenance tasks like cleaning mirrors or lenses, checking bellows, or aligning the beam, which can take several hours per week for CO2 lasers.

Fiber lasers have a fully sealed fiber optic beam path, from the power source to the cutting head, so they are not affected by contaminants like CO2 lasers.

Fiber optic beam paths in fiber lasers ensure that the laser beam is consistently centered through the nozzle.

The factors that affect the laser cutting machines price include:

The power of the laser sheet cutting machine plays a significant role in determining its price. Higher power fiber laser metal cutting machines are generally more expensive than lower power ones, as they can cut through thicker and tougher materials. the max power can reache to 60000w

The size of the work table or cutting area also affects the price. Larger cutting areas require more robust and expensive machine structures, which can increase the overall cost.

Different types of laser souce, Prices are also different. such as CO2 lasers or fiber lasers, have varying costs. Additionally, the quality and reliability of the laser source can also affect the price.

The software and control systems used in laser cutting machines can vary in terms of functionality and ease of use. Machines with advanced software and control systems tend to be more expensive.

Metal fiber laser cutting machine with higher precision and accuracy, as well as better cutting speed, tend to be priced higher. Machines that can deliver consistent and high-quality cuts are usually more expensive due to the advanced technology and components involved.

The reputation and brand value of the manufacturer can also impact the price of laser cutting machines. Well-established brands with a proven track record of quality and service often command higher prices.

Our fiber laser cutting machines have different types of machines to meet customer needs according to their cutting needs and budget. If you are a plate processing manufacturer, our laser sheet cutting machine have several models for you to choose from, such as: F series, P series, G series, S series. For pipe processing needs, we have professional pipe laser cutting machines

In this article, we will mainly introduce our laser sheet cutting machine:

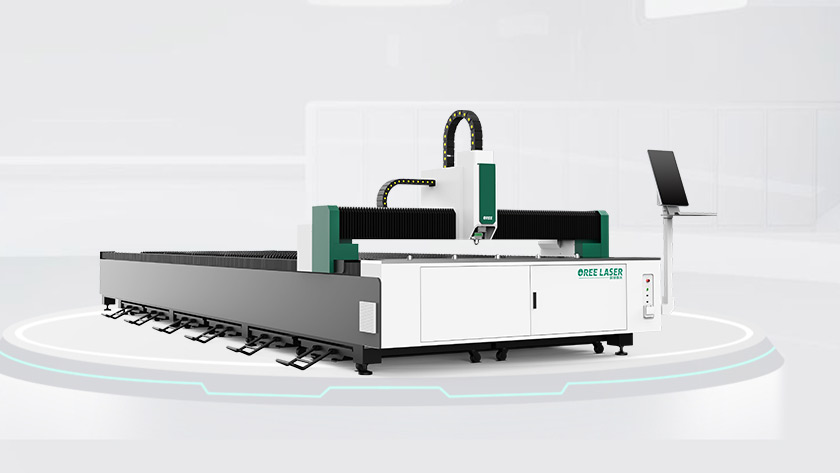

The OR-F Series is a our single-platform sheet metal laser cutting machine that offers affordable pricing, This is our best-selling series of models, making it ideal for customers with limited budgets.

Our F series sheet metal laser cutting machine have the following features:

① Enhanced Quality, Reliable Cutting Performance: The welding bed has undergone iterative upgrades, resulting in a more rational structure layout. This effectively reduces thermal radiation in the cutting area and ensures long-term stability in machine tool operation.

② Easy Module Disassembly and Replacement: The table is designed with modularity, providing strong ventilation and convenient dismounting. This makes it easy to replace components as needed.

③ Efficient Dust Partitioning: By adopting a dual-sided bed exhaust structure and optimizing the air duct, the system achieves a larger caliber and covers multiple areas. This significantly improves the effectiveness of dust extraction compared to intermediate structures.

④ Intelligent Processing for Beginners: The system offers multi-functionality, real-time monitoring, automatic focus, and stable operation. It is designed to be user-friendly and convenient to operate.

⑤ Smart Sensors for Automatic Obstacle Avoidance: Equipped with anti-collision sensors, the system can detect plate warping in advance and automatically avoid obstacles. This reduces maintenance costs associated with the laser head.

⑥ A Remarkable Legacy: This timeless equipment is celebrated for its innovative design, versatility, and has garnered international acclaim. It is manufactured and shipped in multiple units, solidifying its position as a best-selling option worldwide.

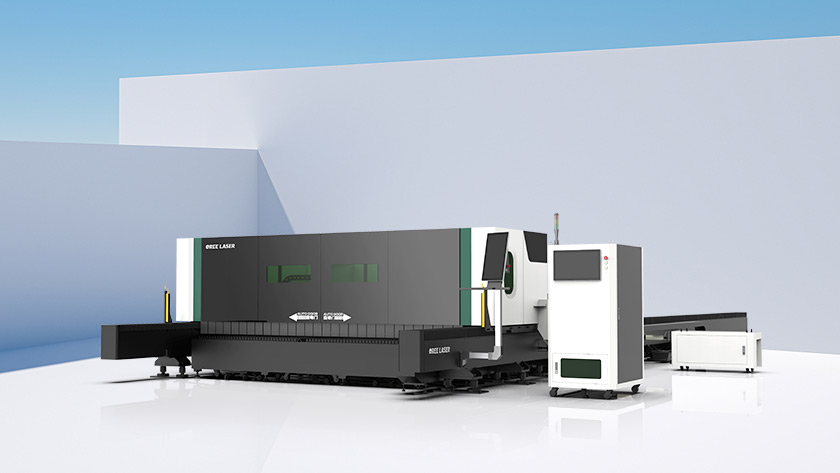

The main feature of the OR-P Series is its built-in protective enclosure design, which greatly improves safety performance, Environmental friendly, Energy saving:

① Sturdy Triangular Welded Bed: The bed is designed using computer finite element analysis, with a layout of triangular steel plates that enhances its rigidity and strength. Additionally, the bed undergoes stress relief annealing to prevent deformation and ensure stability.

② Lightning-Fast Exchange: The metal fiber laser cutting machine features a high and low exchange platform, allowing for quick and complete material exchange. This saves time during loading and unloading operations.

③ 32-inch Ultra-High-Definition Display: The intelligent control system provides real-time monitoring and offers a range of functions for safe production. The machine is equipped with a large, high-definition screen designed with ergonomics in mind.

④ Comprehensive Safety Cover: The front and back of the protective cover have cameras built-in, which are connected to an intelligent control system for monitoring operations. The observation window is made of thick, high-quality glass that meets European safety standards. The protective cover is also made of sturdy sheet metal, ensuring safe production.

⑤ Convenient Containerized Transportation: This compact machine is designed to fit inside a 20GP container, providing protection during transportation and reducing shipping costs. It also makes loading and unloading easier and more efficient.

G Series Large format sheet metal laser cutting machine

The OR-G Series is usually suitable for customers who need processing of larger work areas.

Main features:

① Maximum cutting area: Our metal fiber laser cutting machine can handle big workpieces, with a maximum cutting area of 13100*2550mm. This means we can process large pieces in one go, and our cutting is fast and precise to meet a wide range of cutting needs.

② Bevel cutting: Our OR-GR sheet metal laser cutting machine can cut materials at different angles, from 0 to 45 degrees. The maximum thickness for bevel cutting is 30mm. We offer different types of bevel cutting, such as V type, X type, and Y type, to give you more options.

③ Beam safety light curtain: We take safety seriously. That's why we have installed light curtains on the front and back sides of the beam. These curtains provide full 360-degree protection. They are waterproof, dustproof, and resistant to interference. They are highly sensitive and reliable. With just one button, you can open the safety protection to ensure the workers' safety while the machine is in operation.

④ Partition dust removal system: We have optimized our dust removal system. We have set up a smoke removal pipe on the outside of the bed. This means that any irritating high-temperature smoke generated during cutting will be collected and removed through the external flue of the bed. This ensures a cleaner and healthier working environment.

The above is the main introduction of our best-selling models. You can choose according to your needs, or you can contact us at any time and we will provide you with personalized assistance.

This article has provided a comprehensive analysis of laser cutting machine costs, highlighting the key differences between CO2 and fiber lasers, as well as the factors that influence pricing. And our metal laser cutting machines, specifically their main features, this article serves as a valuable resource for individuals looking to understand the cost dynamics and important considerations when purchasing a laser cutting machine. By examining the disparities between CO2 and fiber lasers and gaining insight into the pricing factors, hope you can make well-informed decisions when selecting the most suitable laser cutting machine for your specific requirements.

So, how much does a metal laser cutting machine cost? please feel free to contact us!! we will give you a competitive price.