09, 2023

by OREE LASER

There are various types of cutting machines available, each designed for specific purposes and materials. Here are some key differences between different cutting machines:

1. Fiber Laser Cutting Machine:

Uses a high-powered laser beam to cut through materials, known as a laser, to effortlessly slice through various materials with utmost precision. It operates swiftly and efficiently, making it an ideal choice for cutting through a wide range of materials such as metal, carbon steel, stainless steel, acrylic, and fabric.

These fiber laser cutters have found widespread application in industries like manufacturing, aerospace and automotive. They have become an absolutely necessary tool, enabling manufacturers to achieve detailed and accurate cuts, enhance productivity, and streamline their production processes.

Metal laser cutters are machines that can easily cut through different materials. They have changed the manufacturing industry by replacing old cutting methods. These machines are very fast, accurate, and can be used for many different purposes. For example, they can create intricate designs on metal sheets. Many industries now rely on laser cutting machines because they are the most effective way to cut materials.

2. CO2 laser cutting machine:

CO2 laser cutters use a strong laser beam made from a mix of gases. This laser beam is aimed at the material to be cut, making it turn into gas or melt, which gives precise and clean cuts. And CO2 laser cutters can cut many different materials like wood, plastic, fabric, and more. Other cutting machines like plasma cutters or waterjet cutters might not be able to cut as many types of materials. In simpler terms, when deciding between a CO2 laser cutter and other cutting machines, it really comes down to what you need for your specific cutting job, the materials you'll be working with, how precise you want the cuts to be, and how much money you have to spend.

3. CNC cutting machine:

CNC (Computer Numerical Control) cutting machine uses a milling cutter to cut shapes out of different materials such as wood, plastic or metal.

CNC cutting machine is cheaper than laser cutting machine. CNC machines can be used to cut a variety of materials, however, laser cutters are often used to cut steel, iron, copper,aluminum, which require high precision cuts.

CNC machine tools have many components, which complicates repair and maintenance. However, fiber laser cutting machines have fewer parts and require less maintenance, low maintenance costs.

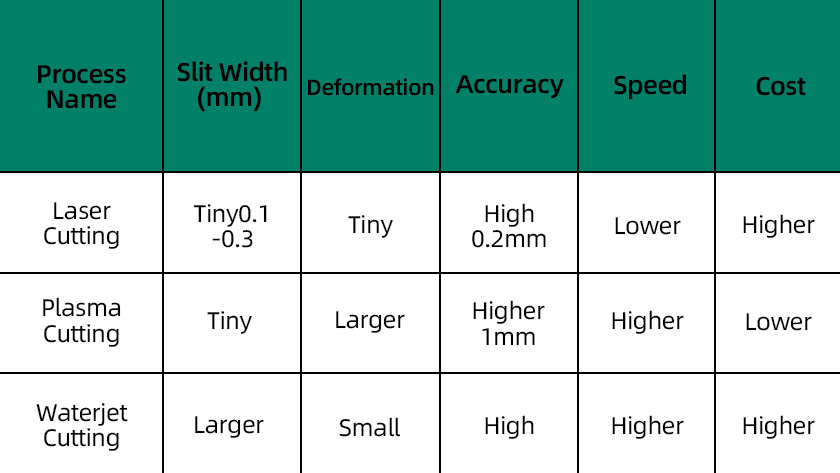

4. Plasma cutting machine:

Is a special type of machine that operates by using a high-speed and mighty stream of a unique gas called plasma. This intense plasma stream is capable of cutting through materials that have the ability to conduct electricity. It is particularly useful in industries such as construction, metal fabrication, and automotive, where it is frequently employed to skillfully slice through thick metal sheets, including strong materials like steel and aluminum.

5. Waterjet cutting machine:

A waterjet cutting machine is a special machine that uses a strong stream of water mixed with tiny particles to cut through different materials. This powerful water stream, combined with the particles, can cut through many things. It is a versatile method that can cut materials like metal, stone, glass, and composites. Many industries, like aerospace, architecture, and art, use waterjet cutting because it is very precise and efficient.

These are just a few examples of cutting machines available, and each has its own unique features, capabilities, and applications depending on the materials and requirements of the user.