10, 2023

by Oree Laser

Guide to Choose the Right Sheet & Tube Fiber Laser Cutting Machine

I. Why choose a sheet & tube fiber laser cutting machine?

A sheet and tube dual-use fiber laser cutting machine has benefits in terms of versatility, cost-effectiveness, efficiency, productivity, precision, and automation. You may streamline your manufacturing processes, save expenses, and enhance overall operational efficiency by investing in a dual-use machines.

Versatility: A dual-use machine can cut both sheet and tube materials, making it a versatile choice for a wide range of applications. This adaptability reduces the need for different machines, lowering equipment costs and freeing up space in the manufacturing plant.

Cost-effectiveness: By combining sheet and tube cutting capabilities into a single machine, you may save money on both capital and operating expenses. You only need to invest in and maintain one equipment, resulting in long-term cost savings.

Increased efficiency: With a dual-use machine, you can switch between sheet and tube cutting operations without making manual adjustments or changing tools. This saves time while increasing overall manufacturing efficiency.

Increased productivity: Dual-purpose machines are intended to easily handle both sheet and tube cutting tasks. This provides for higher productivity because different types of materials can be processed without the requirement for extra equipment or setup time.

Precision and accuracy: Fiber laser cutting technology ensures clean and precise cuts on both sheet and tube materials. This results in less material waste and higher product quality.

II. Understanding Your Needs

Assessing your cutting requirements

It is critical to have an in-depth knowledge of the various cutting operations that the machine must execute when assessing your cutting requirements. Think about the thickness and size of the materials you'll be working with. If you primarily operate with thin sheets, for example, a machine with great precision and a smaller cutting bed may be appropriate. If you routinely work with thicker materials or larger sheets, you may need a machine with a higher power output and a larger cutting area.

Consider the desired cutting shapes and numbers as well. Some machines may be limited in the complexity of forms they can cut, but others provide greater adaptability. If you need delicate or complex cuts, such as curves or angles, a machine with sophisticated capabilities. Similarly, if your production requirements are high and you need to cut big quantities of material, you should search for a machine with quicker cutting rates and automated functions to maximize productivity.

By carefully analyzing your cutting requirements, you can ensure that the sheet and tube laser cutter you select is precisely tailored to meet your specific requirements, resulting in increased productivity and quality in your cutting processes.

Recognizing the materials to be cut

It is critical to determine the precise types of materials you will be working with when identifying the materials to be cut. Laser cutting machines are made to work with a variety of materials, including carbon steel, stainless steel, aluminum, and others. Each material has distinct qualities that necessitate appropriate laser settings and cutting processes.

For example, if you primarily work with metal sheets or tubes, you will require a metal-cutting laser cutting machine. These machines often have larger power outputs and features such as gas assist to optimize the metal cutting process.

It is critical to verify that the machine you use can efficiently handle the materials you deal with. Consider the greatest thickness the machine can cut, the laser wavelength compatibility with the material, and any other characteristics necessary for certain materials. Some laser cutting machines may also have specific attachments or accessories for various materials, which can improve cutting performance and adaptability.

You can get precise and efficient cutting results while maximizing the machine's lifespan by determining the materials to be cut and selecting a laser cutting machine optimized to handle those materials.

III. Application Industries

Sheet and tube laser cutting machines are utilized in a variety of sectors for a variety of purposes. These machines are commonly used in the following industries:

Automotive: In the automotive industry, sheet and tube laser cutting machines are used to cut various elements such as exhaust systems, chassis, and body panels.

Aerospace: These machines are used to cut engine components, wings, and fuselages for aircraft.

Construction: In the construction business, sheet and tube laser cutting equipment are used to cut metal components for buildings, bridges, and other structures.

Medical: In the medical industry, these machines are used to cut surgical tools, implants, and other medical devices.

Electronics: In the electronics industry, sheet and tube laser cutter are utilized to cut precise components for electronic devices.

Signage: In the signage sector, these machines are used to cut lettering, logos, and other designs from diverse materials such as metal.

Furniture: In the furniture sector, sheet and tube laser cutting machines are used to cut accurate and detailed designs in materials such as carbon steel, stainless steel, aluminum.

Energy: In the energy industry, these machines are used to cut components for renewable energy systems such as wind turbines and solar panels.

IV. Oree Laser Sheet & Tube Dual-use Fiber Laser Cutting Machine

OR-PHT Protective Closed Sheet & Tube Fiber Laser Cutting Machine

To enhance personnel safety, the laser cutting machine has a fully enclosed protection system. Its dual-purpose design allows it to cut both sheets and tubes, making it versatile and cost-effective. The machine is outfitted with a professional control system capable of handling various types of pipes and plates, as well as real-time monitoring and warning for high precision and efficient cutting. The welded bed design and fire-resistant insulation technology improve machine stability and safety.The exchange platform allows for speedy and complete material exchange, which saves time. In addition, the machine includes one-key clamping and automatic centering capabilities, as well as adjustable clamping force for cutting angle steel and channel steel. When compared to standard designs, the exhaust structure on both sides of the bed, together with enhanced air ducts, improves the exhaust effect. Furthermore, the beam is built of fifth-generation aircraft aluminum alloy that has been heat treated with T6 for maximum strength, better ductility, decreased weight, and faster movement.

OR-EHT Exchange Table Sheet & Tube Fiber Laser Cutting Machine

The plate and tube integrated design is inexpensive and practical, and it can meet a wide range of cutting circumstances while being cost-effective. A professional plate and tube integrated control system can process a wide range of tubes and plates with high cutting accuracy, high cutting efficiency, and easy and convenient operation. The intelligent exchange platform allows for incredibly fast exchange, saving time on loading and unloading. The latest generation of welding bed design and fire-resistant insulation technology can improve bed stability and machine body protection. One-key clamping with automated centering; pneumatic clamping with adjustable clamping force; dedicated support structure to prevent pipe sagging and distortion. The structure is built with air extraction on both sides, and the large-diameter and multi-zone optimized upgrading air duct can greatly increase extraction compared to the middle air extraction structure.

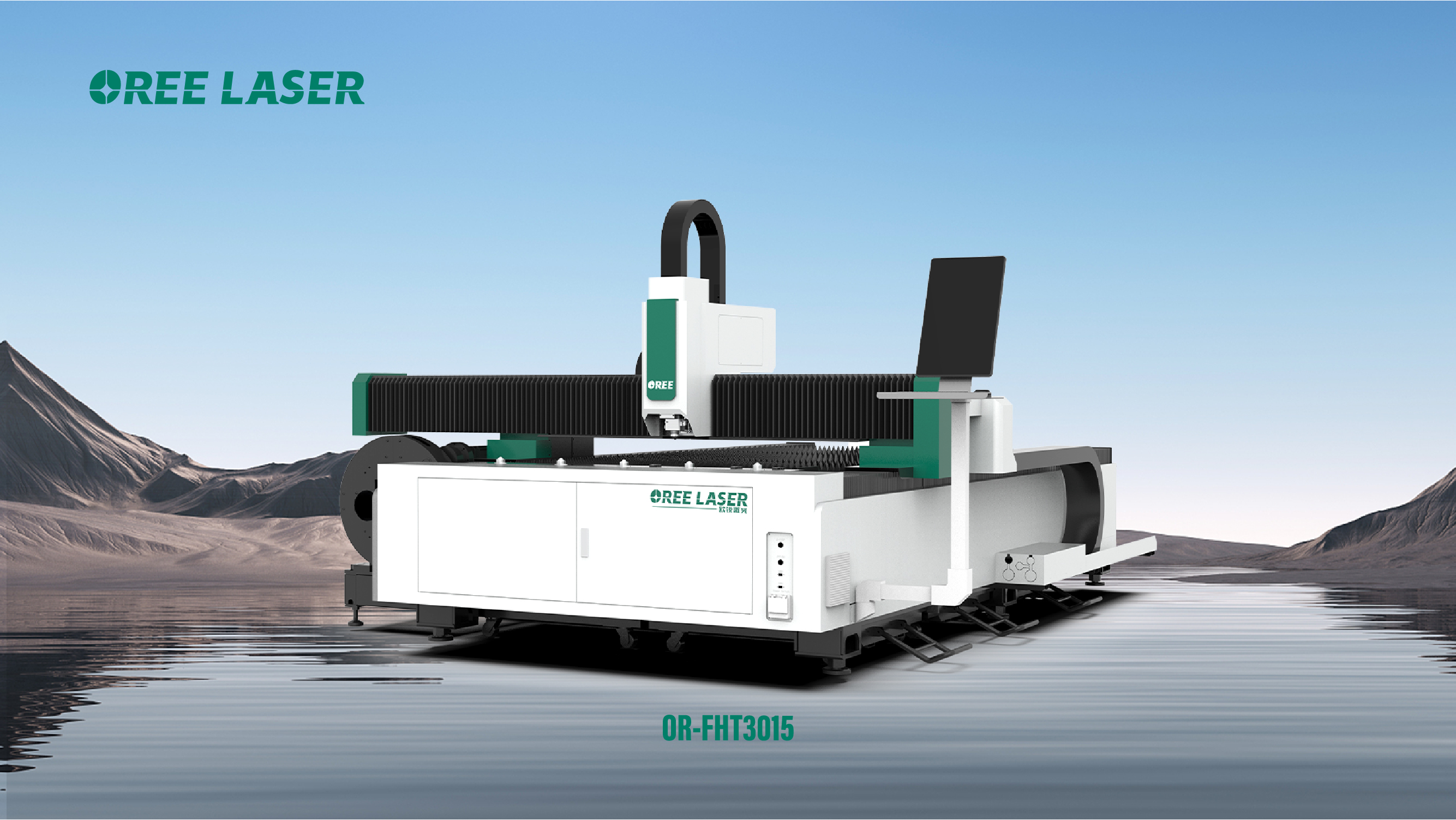

OR-FHT Dual-use Sheet & Tube Fiber Laser Cutting Machine

Dual-use sheet and tube cutting machine that is efficient and practical, saving money and space while enhancing production efficiency. Pneumatic clamping with adjustable clamping force; specialized support structure to prevent pipe sagging and distortion. Equipped with a professional control system that is stable, safe, and efficient for both sheet and tube cutting; real-time monitoring with an abnormal warning; collision avoidance sensing mechanism; and several advanced cutting processes. High-strength welded bed design for strong structural stability, effectively limiting heat radiation area in the cutting zone; integrated with modern fire-resistant insulation technology to assure the machine's long-term stability. The working table is designed in a modular format for easy disassembly, maintenance, and time savings for customers in table maintenance. Optional zone dust removal feature, with large-diameter exhaust structure design on both sides of the bed, optimized and upgraded air ducts in many regions, resulting in a greatly improved exhaust effect.

If you are interested in our dual-use fiber laser cutting machine, please don't hesitate to contact us.