11, 2023

by Oree Laser

Is purchasing a fiber laser cutting machine a worthwhile investment?

In today's rapidly evolving manufacturing industry, businesses are constantly seeking ways to improve efficiency, increase productivity, and enhance the quality of their products. One technology that has gained significant popularity is fiber laser cutting machines. These advanced machines offer precise and efficient cutting capabilities, making them a tempting investment for many companies. However, before making such a significant purchase, it's crucial to evaluate whether investing in a fiber laser cutting machine is truly worthwhile. In this blog post, we will explore the key factors to consider when deciding if purchasing a fiber laser cutting machine is a worthwhile investment.

1. Cost and Financial Considerations:

The cost of purchasing a fiber laser cutting machine is one of the most important aspects to consider. Prices for these laser cutters can range from tens of thousands to hundreds of thousands of dollars, depending on the features and capabilities. A detailed cost-benefit analysis is required to evaluate whether the anticipated benefits outweigh the initial investment. Consider the predicted return on investment, cost savings from enhanced efficiency, material waste reduction, and future revenue growth. When weighing the cost and financial implications of purchasing a fiber laser cutter, it is critical to examine the cost and financial consequences. These machines can have a high initial cost, which can be intimidating. However, it is important to consider the long-term benefits and cost reductions in addition to the initial spending.

Return on Investment (ROI): Conduct a comprehensive analysis to establish the expected ROI of purchasing a fiber laser cutting machine. Consider enhanced production, less material waste, and potential income growth. Evaluate how long it will take to pay off your investment and whether it is in line with your company's financial objectives.

Cost Savings: Compared to traditional cutting methods, fiber laser cutter provide significant cost-saving advantages. Because these machines are highly efficient, production time and personnel expenses are decreased. Furthermore, its precision cutting capabilities reduce material waste, resulting in significant savings in raw material costs. Assess whether the prospective cost reductions outweigh the initial outlay.

Maintenance and Operating Costs: While fiber laser cutting devices require less maintenance than other cutting processes, ongoing operational costs must be considered. Examine the costs of power use, gas supply, and routine maintenance to verify they are in line with your budget and financial expectations.

Scalability and Future Growth: Consider your company's long-term potential and growth trajectory. Will the fiber laser cutting equipment meet your future requirements? Examine whether the machine's capabilities and specs correspond to your anticipated growth, ensuring that your investment remains worthwhile as your firm grows.

By carefully evaluating the cost and financial considerations, businesses can determine if investing in a fiber laser cutting machine aligns with their budget, financial goals, and growth plans. While the initial investment may seem significant, the potential cost savings, increased productivity, and improved product quality can make it a worthwhile long-term investment.

2. Increased Efficiency and Productivity:

Fiber laser cutting machines provide remarkable cutting precision and speed, allowing for faster production cycles and increased efficiency. These devices, as compared to traditional cutting methods, can dramatically reduce the time necessary to execute jobs, resulting in enhanced production. Furthermore, the fiber laser cutting machines' automated features and extensive software capabilities allow for easy interaction with other manufacturing processes, increasing total efficiency.

a) Speed and Precision: The ability of laser cutting machine to cut materials at fast speeds while keeping precision is one of its most significant advantages. These machines can cut through a variety of materials with excellent accuracy and consistency, including metals, plastics, and composites. This precision enables faster and more efficient manufacturing processes, resulting in higher productivity.

b) Minimal Material Waste: When compared to traditional cutting methods, fiber laser cutter are highly efficient, resulting in minimal material waste. These machines' precise cutting capabilities ensure that each cut is accurate, avoiding the need for extra cuts or finishing work. This results in significant cost savings in raw material expenses and reduced environmental impact.

c) Reduced Labor Costs: The advanced automation features of fiber laser cutting machines reduce the need for manual labor, resulting in reduced labor costs. These machines can operate continuously, requiring minimal operator intervention, freeing up employees to focus on other critical tasks.

d) Increased Output: The increased speed and precision of fiber laser cutting machines allow for faster production times and increased output. This increased output can lead to increased revenue and growth opportunities for businesses.

In conclusion, investing in a fiber laser cutting machine can greatly improve production process efficiency and productivity. These laser cutters' speed, precision, and automation characteristics can reduce material waste, labor costs, and boost output. Businesses can enhance their bottom line and acquire a competitive advantage in the market by enhancing efficiency and productivity.

3. Versatility and Flexibility:

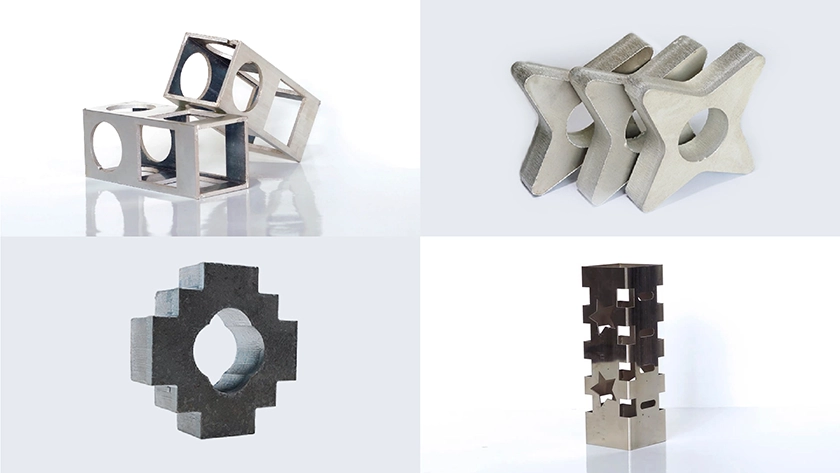

The versatility of fiber laser cutting machines is another advantage. These machines can cut a variety of materials such as carbon steel, stainless steel, aluminum, and others. This adaptability enables enterprises to vary their product offerings and reach a larger customer base. Furthermore, fiber laser cutter can easily handle elaborate designs and complex shapes, giving businesses the flexibility to meet a variety of consumer requests. Another significant benefit of purchasing a fiber laser cutting machine is its versatility and adaptability to a wide range of materials and applications. These machines can cut a variety of materials with varying thicknesses and complexities, making them appropriate for a wide range of industries and production processes.

a) Material Compatibility: Fiber laser cutting machines can efficiently cut through materials such as metals (including steel, aluminum, and copper) and even reflecting materials such as brass and copper. This adaptability enables organizations to meet a wide range of customer requests and grow their product offerings.

b) Wide Range of Applications: Fiber laser cutting machines can be utilized for a variety of applications, including but not limited to metal fabrication, automotive production, aerospace, electronics, signage, and architectural industries. This adaptability helps organizations to respond to changing market demands and pursue new possibilities.

c) Customization and Complex Designs: The fiber laser equipment' precise cutting capabilities allow for the fabrication of elaborate and complex designs with high accuracy. This opens the door to customisation and individualized products, which can provide a substantial competitive advantage in businesses that value originality and customization.

d) Cutting Thick Materials: Laser cutters are excellent at easily cutting thick materials. This skill is especially useful in industries that demand thick metal cutting, such as shipbuilding, construction, and heavy machinery production. The capacity to efficiently handle thick materials can result in cost savings and enhanced production processes.

Fiber laser cutting machines are a beneficial investment for organizations trying to grow their capabilities, adapt to various consumer needs, and remain competitive in a fast expanding market due to their versatility and flexibility. These machines provide firms with the ability to adapt and grow in a variety of industries by offering a wide range of applications, material compatibility, and customization choices.

4. Enhanced Product Quality:

Investing in a fiber laser cutting machine can considerably increase the end product's quality. These machines' accurate and clean cuts ensure less material distortion and reduced post-processing requirements. This not only improves the products' aesthetic appeal but also lowers the need for additional finishing labor. Increased consumer happiness, repeat business, and a stronger brand reputation can all be attributed to improved product quality. Investing in a fiber laser cutting machine can greatly improve product quality. These machines' advanced technology and precision enable clean, accurate, and high-quality cuts, resulting in superior product outputs.

a) Clean and Precise Cuts: Fiber laser cutting machines generate narrow and precise cuts by utilizing a concentrated laser beam. This avoids the requirement for secondary finishing procedures like deburring or polishing that are frequently necessary with conventional cutting methods. Clean cuts made by fiber laser cutters ensure smooth edges and accurate measurements, improving the overall quality of the finished product.

b) Minimal Tail Materials: Traditional cutting processes, such as mechanical cutting, might generate thermal distortion or mechanical stress on the material being cut. Fiber laser cutting equipment, on the other hand, produce few heat-affected zones, lowering the danger of material distortion. This is especially useful in industries requiring high precision and dimensional accuracy, such as aerospace or medical equipment manufacture.

c) Improved Consistency: Fiber laser cutting equipment provide consistent cutting results, assuring consistency across several pieces or batches. These machines' precise control and automation capabilities reduce variation in the cutting process, resulting in products with uniform dimensions, forms, and quality. This is especially significant in businesses where parts must be standardized and interchangeable.

d) complex Geometries and Intricate: Because of the great precision and versatility of fiber laser cutting machines, complicated geometries and intricate designs may be easily created. This enables firms to experiment with new product designs and meet the demands of customers looking for unique and aesthetically beautiful items. The ability to correctly make delicate cuts improves the overall product quality and appeal.

e) Quality Control and Traceability: Advanced monitoring systems and quality control features are frequently included with fiber laser cutting machines. These systems are capable of detecting and correcting any deviations or errors that occur during the cutting process, ensuring that only high-quality goods are created. Furthermore, the ability to monitor and trace each cut piece gives essential data for quality control and simplifies compliance with standards and regulations.

Investing in a fiber laser cutting machine improves not only the efficiency and productivity of manufacturing operations, but also the overall quality of the finished products. Superior product outputs are aided by clean and precise cuts, less material distortion, greater consistency, and the capacity to handle complicated designs. Businesses may develop a good reputation, attract more customers, and eventually boost their profitability by providing high-quality products.

5. Long-term Cost Savings:

While the initial cost of a fiber laser cutting machines may appear high, it is critical to consider the long-term cost reductions it can provide. When compared to traditional cutting procedures, these machines are highly efficient and need less maintenance. Furthermore, less material waste and better manufacturing processes can result in significant cost savings over time. Before making a decision, businesses should consider the potential long-term financial rewards. Businesses can save significantly on long-term costs by investing in a fiber laser cutting machine. While the initial investment may appear high, the efficiency, productivity, and operational benefits of these machines can result in significant cost savings over time.

a) Less Material Waste: Fiber laser cutting equipment provide precise and accurate cuts, resulting in less material waste. The capacity to cut intricate designs and optimize material consumption guarantees that raw materials are used to their full potential, lowering overall material costs. Furthermore, the clean cuts produced by fiber lasers reduce the need for secondary finishing procedures, decreasing material waste and associated costs even further.

b) Lower Labor Costs: Fiber laser cutting machines are fully automated and require little to no human intervention. This not only reduces labor expenses, but also removes the possibility of human error, resulting in uniform and high-quality cuts.

c) Increase production Output: laser cutting machine' high speed and precision considerably boost manufacturing output. When compared to traditional cutting processes, these machines can cut through materials at a faster rate, allowing firms to execute orders more rapidly. Increased output enables organizations to take on more projects, meet consumer needs, and create more income.

Overall, companies can save significantly on long-term costs by investing in a fiber laser cutting machines. These machines' reduced material waste, lower labor costs, better output, energy efficiency, and versatility all lead to improved profitability and a stronger bottom line. Businesses can allocate resources more effectively and achieve long-term growth by improving operational efficiency and lowering costs.

Purchasing a fiber laser cutting machine can be a worthwhile investment for industrial companies. However, before making a decision, it is critical to thoroughly consider the cost, potential advantages, and long-term repercussions. Businesses can make an informed decision that matches with their specific objectives and goals by evaluating variables such as cost-effectiveness, higher efficiency, adaptability, improved product quality, and long-term cost savings. Finally, investing in a fiber laser cutting equipment can provide a competitive advantage, improve manufacturing processes, and drive long-term corporate success. If you are intrigued by our fiber laser cutting machine and would like to explore how it can benefit your company's investment, please don't hesitate to contact us!