11, 2023

by Oree Laser

How to Choose the Right Hand-held Laser Cleaning Machine?

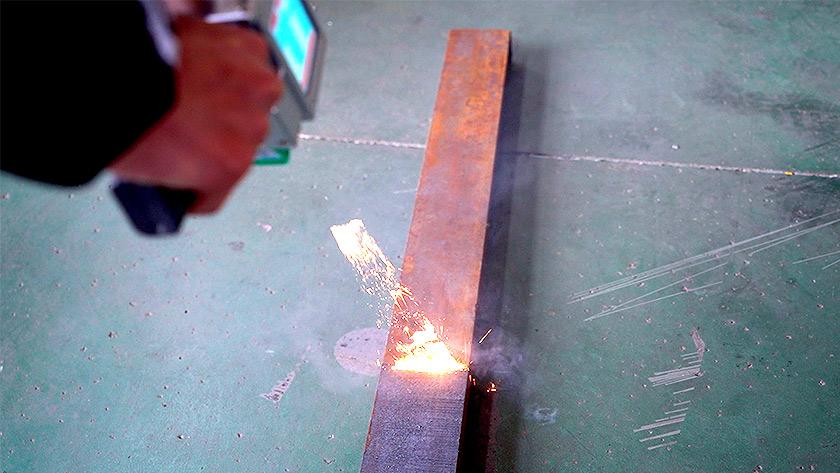

A handheld laser cleaning machine is a portable device that uses laser technology to clean and remove contaminants from various surfaces. It is controlled by hand and allows for easy movement and precision cleaning in a range of applications.

These machines discharge a highly focused laser beam at surface contaminants, vaporizing or abating them. The power level and pulse duration of the laser beam can be adjusted, allowing for fine control and excellent cleaning without damaging the underlying surface.

Handheld laser cleaners are frequently utilized in industries such as manufacturing, automotive, aerospace, and restoration. Rust, paint, grease, scale, oxide coatings, and other unwanted residues can be successfully removed from stainless steel, carbon steel, brass, aluminum, and other materials.

These machines have safety features that keep the operator safe while in use. This includes beam shut-off sensors, interlocks, and protective eyewear. They are also lightweight and ergonomic, enabling for extended durations of cleaning comfort and ease.

A handheld laser cleaner is non-contact, which means it has no contact with the surface being cleaned. This reduces the possibility of scratches or surface damage, making it appropriate for sensitive materials.

Overall, handheld laser cleaning machine offer a versatile, effective, and environmentally friendly surface cleaning solution. They provide a faster and more precise cleaning technique than previous methods, decreasing downtime and increasing output. Because of their portability and ease of use, these machines are becoming increasingly popular in a range of industries where effective cleaning is necessary.

B. Importance of choosing the right machine

Cleaning efficiency: Different handheld laser cleaner have different power levels, pulse durations, and spot sizes. Choosing a machine that fits the cleaning requirements of your individual application ensures effective and efficient cleaning. A machine with insufficient power may be unable to remove obstinate contaminants, whereas a machine with enough power may damage the surface.

Surface compatibility: Surface material, texture, and sensitivity can all vary significantly. It is essential to choose a handheld laser cleaning machine that is suitable for the surface to be cleaned. Different machines may have different beam characteristics or wavelength options that are more appropriate for specific materials. The use of the wrong machine on a delicate or sensitive surface may result in damage or discoloration.

Considerations for safety: Laser cleaning involves the use of high-powered lasers, which might be harmful if not used properly. It is important to choose a machine that includes adequate security elements such as beam shut-off sensors, interlocks, and protective eyewear. Furthermore, purchasing a machine from a reputable manufacturer who adheres to safety standards helps to ensure the highest level of user safety.

Durability and reliability: Investing in a high-quality handheld laser cleaning machine ensures this. Machines from valued manufacturers are built to last and are less likely to break down or malfunction. Choosing dependable equipment saves downtime and maintenance costs, resulting in better long-term value for money.

Long-term cost considerations: While the initial cost of a handheld laser cleaning machine is significant, it is equally necessary to consider the long-term maintenance and operational costs. Some machines may necessitate routine maintenance or the replacement of consumable parts, raising the total cost of ownership. Evaluating a machine's long-term financial effects helps in establishing its value for money.

II. Considerations for choosing a laser rust cleaner

Power and energy density

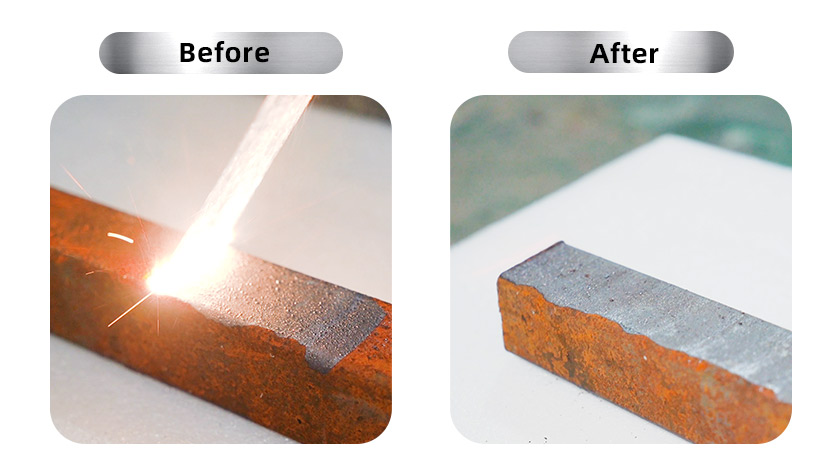

Power is an important factor in affecting the cleaning efficiency and speed of the machine. Higher power means a more strong laser beam that can remove stains and surface coatings faster. However, it is critical to achieve a balance because using too much power can potentially damage the surface being cleaned. As a result, it is critical to pick the right power level based on the application requirements. Another essential factor is energy density, which represents the distribution of energy per unit area of the laser beam. Higher energy density provides for more effective stain removal, but too high energy density might cause surface damage. As a result, the energy density should be selected based on the specific cleaning requirements and the material being treated.

Wavelength

The wavelength determines the precise range of materials that can be effectively cleaned by the laser. For different wavelengths of light, different materials have varied absorption qualities. By choosing the right wavelength, you can ensure that the laser energy is efficiently absorbed by the target material, resulting in successful cleaning.In order to select the proper wavelength for the handheld laser cleaning machine, it is critical to evaluate the specific cleaning requirements as well as the type of the materials to be cleaned. This will provide excellent cleaning efficiency and prevent any potential surface damage.

Pulse duration

The pulse duration is important in the cleaning process because it impacts how the laser beam interacts with the target material. Shorter pulse durations are often more effective for eliminating impurities because they provide high peak power and fine control over the laser energy. Consideration of a handheld laser cleaning machine's pulse duration ensures that you select a device that is appropriate for the targeted cleaning applications and materials, resulting in effective and safe cleaning outcomes.

Spot size and scanning area

When cleaning complicated or detailed surfaces, a smaller spot size provides for more exact cleaning. However, it is critical to ensure that the spot size is large enough to effectively cover the necessary cleaning area. Furthermore, it is critical to select a handheld laser cleaning equipment with a scanning area appropriate for the required purpose. Larger scanning areas enable faster cleaning of larger surfaces, whilst smaller scanning areas are more suited to focused or localized cleaning. When choosing a handheld laser cleaner, it is critical to examine the specific cleaning requirements as well as the size of the surfaces to be cleaned. Finding the ideal balance between spot size and scanning area guarantees efficient and effective cleaning while increasing production.

Cooling system

Laser cleaning generates heat, which, if not correctly managed, can lead to overheating and probable laser component damage. A dependable cooling system is required to drain heat and maintain the laser's ideal operating temperature. Water cooling devices, absorb and dissipate the heat generated by the laser. They provide improved cooling efficiency and are appropriate for high-power lasers or applications requiring continuous operation.

Safety features

Laser cleaning produces bright light that might be hazardous to the eyes. The handheld laser cleaning machine should contain or advocate the usage of laser safety eyewear that are appropriate for the laser's wavelength and strength. Emergency stop button: In the event of any unforeseen hazards or crises, an emergency stop button should be easily accessible on the equipment.

Price & Cost

Laser cleaning machines are more expensive than other traditional cleaning machines. The main difference is that laser cleaners can be reused. The laser cleaning machine price varies depending on its configuration. For example, higher power laser generators will cost more, and pulsed laser cleaners are generally more expensive than continuous wave (CW) laser cleaners.

In the current market, A 1000W laser cleaning machine price around $3,500. A 1500W laser rust removal machine price between $4000 and $5500, and a 2000W high-power laser cleaning machine costs about $5,800. The 3000W laser cleaning machine price about $8,000. An autonomous laser cleaning system with a CNC controller or robot will cost more.

The most affordable 3-in-1 laser welding, cleaning, and cutting machine price between $3,500 and $9,500, depending on whether the fiber laser power supply is 1000W or 3000W.

Even if the configurations are comparable, the prices from various manufacturers may differ. This is because the pricing includes elements such as brand, after-sales support, and other considerations in addition to the configuration.

III. Oree Laser Hand-held Laser Rust Removal Machine (OR-LC-B, OR-LC-C)

The OR-LC-B is a versatile and effective handheld cleaner that may be used for a variety of cleaning tasks. Its lightweight and ergonomic design allows for simple control and comfortable operation.

This machine is equipped with metal safety sensors and automatic light locking during movement, assuring safe and smooth operation.

Although this compact machine is small in size, it provides powerful and effective cleaning results. It removes the need for chemical substances and provides excellent precision, cleanliness, and efficiency in surface cleaning.

This laser cleaning machine is both environmentally friendly and reliable, as it causes almost no damage to the substrate's surface. It is capable of solving cleaning issues which traditional method cannot.

This laser cleaner includes a professional cleaning system, allows different cleaning processes with one-touch settings, making equipment cleaning more intelligent and efficient.

OR-LC-B, non-contact cleaning technology efficiently removes pollutants without scraping or damaging the surface of the substrate. This ensures the underlying material's safety and protection while avoiding secondary contamination.

The OR-LC-B Handheld Laser Cleaner is the right choice for more efficient and effective cleaning. Its extensive features and capabilities make it a dependable and efficient tool for a variety of cleaning duties.

The OR-LC-B is a compact and efficient cleaner with numerous advantages. It is simple to control and incorporate into automation systems due to its compact size and lightweight design. It does not require chemical, making it both ecologically friendly and safe to use.

One of its important characteristics is its capacity to clean surfaces with excellent precision and cleanliness. It can precisely target certain areas and eliminate impurities, offering a comprehensive and efficient cleaning operation. This makes it a great choice for situations requiring precise cleaning.

The OR-LC-B is designed with the user in mind. Its handheld cleaning head features an innovative design with a completely sealed structure to keep dust out of the optical parts. The ergonomic body engineering design ensures an appealing grip, enabling one-handed operation possible. Furthermore, the protective lens has a drawer structure, making it simple to replace when appropriate.

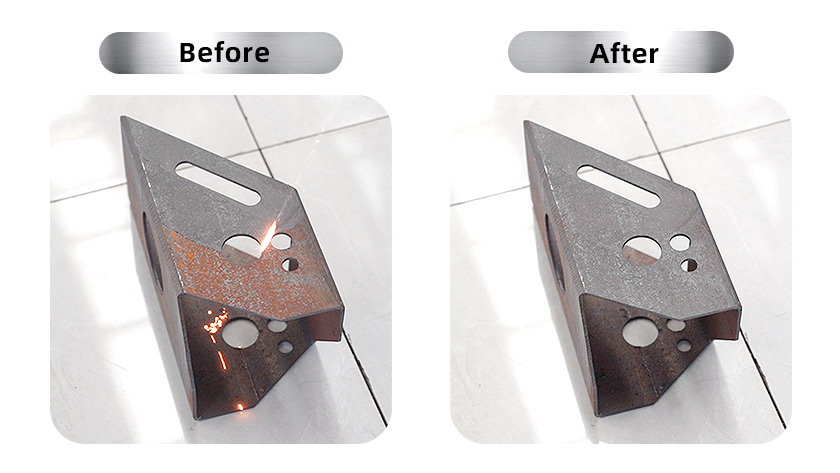

The OR-LC-B performs well in rust removal applications and has a good production efficiency. Its precision cleaning skills allow it to precisely target rusty spots, efficiently eliminating rust and restoring the surface to its former state.

This product has many benefits, including precise cleaning for accurate results, simple operation with simple power-on functionality, and the ability to use it as a handheld device or integrate it with a robot for automatic cleaning. Its low-maintenance cleaning method assures consistent performance, while its safety and environmental characteristics, such as the lack of chemical cleaning solutions and consumables, make it a safe and environmentally friendly choice.

The OR-LC-B Handheld Laser Cleaning Machine is an excellent choice for individuals looking for precise, efficient, and environmentally friendly cleaning. Its advanced capabilities and user-friendly design make it a useful tool for a variety of applications.

IV. Application Industries of laser rust cleaning machine

Handheld laser cleaners have many applications in a variety of industries. Handheld laser cleaning machine are extensively used in the following industries:

Electronics and Semiconductors: Handheld laser cleaners are used to clean sensitive electronic components, circuit boards, connectors, and semiconductors. They can remove solder residues, glue, and other pollutants without causing damage to the sensitive electronic components.

Medical and Pharmaceutical: Handheld laser cleaners are used to clean surgical instruments, medical devices, and pharmaceutical manufacturing equipment in the medical and pharmaceutical industries. They are capable of effectively removing pollutants and sterilizing surfaces.

Manufacturing and Automotive: Handheld laser cleaners are used in the manufacturing and automotive industries for surface preparation, corrosion and paint removal, and cleaning of metal components. They are capable of cleaning the surfaces of machinery, engines, molds, and other industrial equipment effectively.

Aerospace and Aviation: Handheld laser cleaners are used for the repair and cleaning of aircraft components such as turbine blades, engine parts, and landing gear. They are capable of removing impurities, coatings, and oxidation from surfaces without causing damage.

If you want to learn more about laser cleaning machines or if you are interested in our laser cleaner, please feel free to contact us.