10, 2019

by Oree Laser

The role of shielding gas in laser welding

In laser welding, shielding gas will affect the weld formation, the weld quality, the weld depth, and the weld width, etc. In most cases, the blowing of the shielding gas will have a beneficial effect on the weld, but bad use may also bring adverse effects.

The positive effect of shielding gas on laser welding

●Proper blowing of the shielding gas will effectively protect the weld pool from oxidation and even avoid oxidation;

●Proper blowing of the shielding gas can effectively reduce the splash generated during the welding process and protect the focusing mirror;

●Proper blowing of the shielding gas can promote the uniform spreading of the weld pool during solidification so that the weld is uniformly formed and beautiful;

●Proper blowing of the shielding gas can effectively reduce metal vapor or the shielding effect of the plasma cloud on the laser so that the laser energy reaching the surface of the workpiece, and thereby increase the effective utilization rate of the laser;

●Proper blowing of the shielding gas can effectively reduce weld porosity.

As long as the gas type, gas flow rate, and blowing method are correctly selected, the ideal effect can be obtained. However, improper use of shielding gas can also have adverse effects on welding.

Adverse effects of improper use of shielding gas on laser welding

●Improper blowing of shielding gas may cause the weld to deteriorate;

●Choosing the wrong type of gas may cause cracks in the weld, and may also lead to the reduction of weld mechanical properties;

●Choosing the wrong type of gas may cause the weld to be more oxidized (whether the flow is too large or too small), or it may cause the weld pool metal to be seriously disturbed by the external force to cause the weld to collapse or form unevenly;

●Choosing the wrong gas blowing method will result in the weld not achieving the protective effect or negatively affecting the weld formation;

●Insufflation of the shielding gas will have a certain effect on the weld penetration, especially when the thin plate is welded, the weld penetration will be reduced.

Types of the shielding gas

The commonly used laser welding shielding gas is mainly N2(nitrogen), Ar(argon), He(helium), and their physicochemical properties are different, so the effect on the weld is different.

●Nitrogen N2---can be used for welding shielding gas of stainless steel

The ionization energy of N2 is moderate, higher than that of Ar, lower than that of He, and the ionization degree under the action of laser is general, which can better reduce the formation of plasma cloud, thereby increasing the effective utilization of laser. Nitrogen can react with aluminum alloy and carbon steel at a certain temperature to produce nitrides, which will improve the brittleness of welds and reduce the toughness, and have a great adverse effect on the mechanical properties of the weld joint. Therefore, it is not recommended to use nitrogen to protect the weld of aluminum alloy and carbon steel.

The nitride produced by the chemical reaction between nitrogen and stainless steel can improve the strength of the welded joint and improve the mechanical properties of the weld. Therefore, nitrogen can be used as a shielding gas when welding stainless steel.

●Argon Ar--- high-cost performance, the most conventional shielding gas

The ionization energy of Ar is relatively low, and the degree of ionization is high under the action of the laser, which is not conducive to controlling the formation of the plasma cloud, and will have a certain influence on the effective utilization of laser. However, the activity of Ar is very low, and it is difficult to react with common metals, and the cost of Ar is not high. Besides, the density of Ar is large, which is conducive to sinking above the weld pool and can better protect the weld pool. Therefore, Ar can be used as a conventional shielding gas.

●Helium He---the best but also the most expensive shielding gas

He has the highest ionization energy and low ionization under the action of laser. It can control the formation of the plasma cloud very well, and the laser can work well on metal. Moreover, the activity of He is very low, and it does not chemically react with metals, so it is a good weld shielding gas. However, the cost of He is too high to be suitable for mass production products. He is generally used for scientific research or products with very high added value.

Shielding gas blowing method

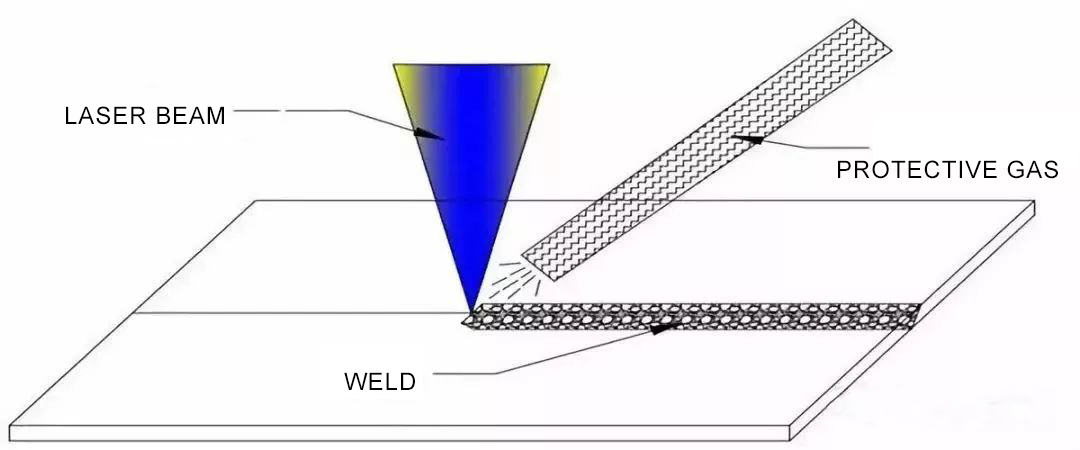

There are two main ways to blow the shielding gas: one is the parallel side blowing shielding gas, as shown below:

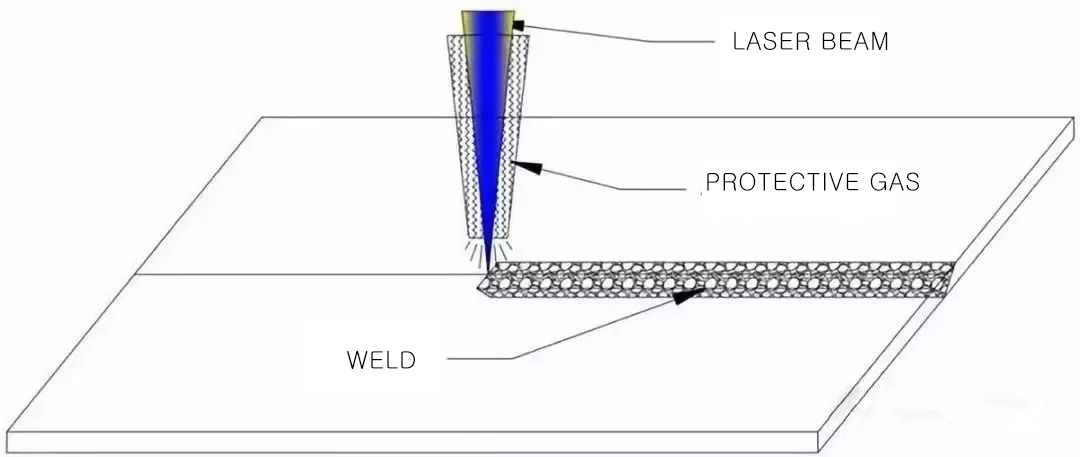

The other is the coaxial shielding gas, as shown below:

The choice of the two method of blowing is a comprehensive consideration of various aspects. It is recommended to use a side blowing shielding gas.

The principle of selection of the shielding gas blowing method is as follows: the straight line weld is good with the side shaft, and the flat closed pattern is coaxial.

First of all, it should be clear that the so-called weld is “oxidized” is only a common name, theoretically means that the material to be reacts with oxygen, nitrogen, helium at high temperatures.

Preventing the weld from being “oxidized” is to reduce or prevent such harmful components from coming into contact with the weld metal at high temperatures. This high-temperature condition is not only the molten pool metal but the entire period from when the weld metal is melted until the molten pool metal solidifies and its temperature drops below a certain temperature.

For example, titanium alloy can quickly absorb hydrogen when temperature is above 300℃, oxygen can be quickly absorbed when it is above 450℃, and nitrogen can be quickly absorbed when it is above 600℃. Therefore, the titanium alloy weld is subjected to effective protection after solidification and the temperature is lowered to below 300℃, otherwise, it will be “oxidized”.

It is not difficult to understand from the above description that the blowing of the shielding gas not only needs to protect the weld pool at the right time but also protects the newly solidified area that has been welded. Therefore, the parallel side blowing shielding gas is generally used, because the parallel side blowing shielding gas has a wider protection range than the coaxial protection mode, especially for the area where the weld seam has just solidified.

For engineering applications, not all products can use side blowing shielding gas. For some specific products, only coaxial shielding gas can be used. Specifically, it needs to be selected from the product structure and joint form.

The choice of specific shielding gas blowing method

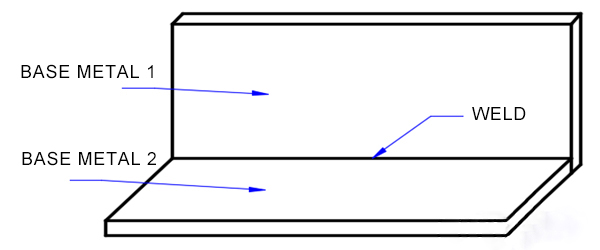

●Straight line weld

As shown in the figure, the weld shape of the product is linear, and the joint form is a butt joint, a lap joint, a female corner joint or a welded joint. This type of product is preferably provided by side blowing shielding gas.

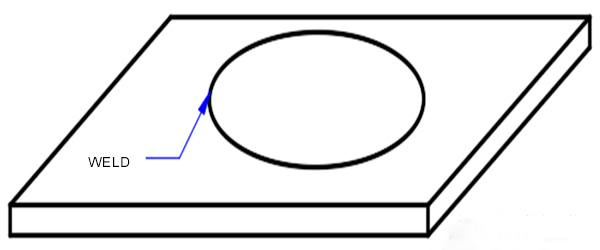

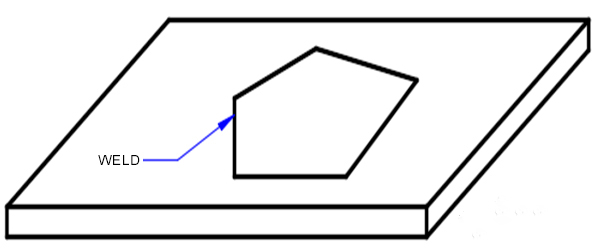

●Flat closed graphic weld

The selection of the shielding gas affects the quality, efficiency, and cost of welding production. However, due to the diversity of welding materials, the selection of welding gas is also complicated in the welding process. It is necessary to comprehensively consider the welding material, welding method, welding position, and the required welding results. Welding test can be used to select a more suitable welding gas for better welding results.

Professional Laser Cutting Machine Manufacturer - OreeLaser