09, 2023

by Oree Laser

CO2 Laser VS Fiber Lasers - Which One Should You Buy?

The decision between a CO2 laser and a fiber laser is influenced by several factors, including your specific application requirements, budget, and personal preferences. Here are some key considerations to help you make an informed decision:

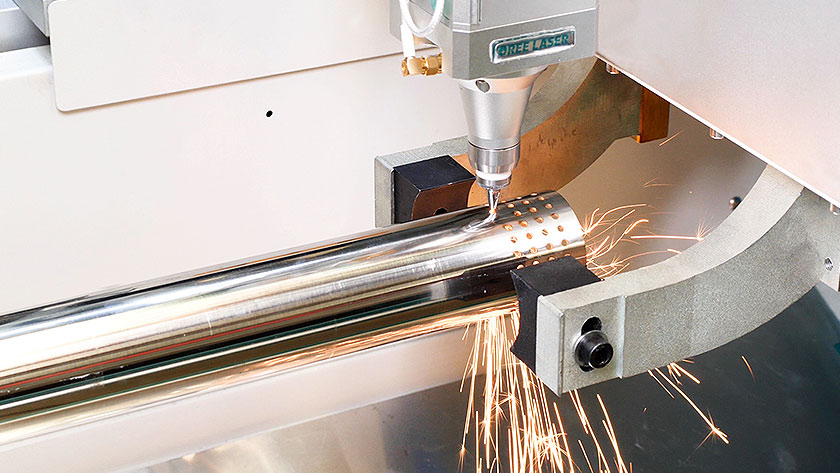

About Fiber Laser Cutting Machine

A fiber laser cutting machine uses a solid-state laser source, typically made of a fiber optic cable doped with rare-earth elements like erbium, ytterbium, or neodymium. These lasers generate a high-intensity laser beam that is guided through the fiber optic cable and then focused onto the material to be cut. Fiber lasers are known for their high cutting speeds, precision, and efficiency. They are particularly effective for cutting metals, including stainless steel, aluminum, brass, and copper. Fiber laser cutting machine is widely used in industries such as automotive, aerospace, and metal fabrication.

About Co2 Laser Cutter

A CO2 laser cutter is a machine commonly used for cutting and engraving materials. It utilizes a CO2 laser to generate a high-energy beam that is focused onto the material to be cut. The intense heat of the laser beam vaporizes or melts the material, allowing for precise and clean cuts. CO2 laser cutters are versatile and can be used on a wide range of materials, including wood, acrylic, leather, fabric, and more. They are widely used in various industries, such as manufacturing, signage, arts and crafts, and prototyping. CO2 laser cutters offer high precision, speed, and flexibility, making them a popular choice for many applications.

Difference between Fiber Laser vs. CO2 Laser

Material Compatibility: Consider the type of materials you will be working with. CO2 lasers are better suited for cutting and engraving non-metallic materials like wood, acrylic, and leather. Fiber laser cutting machine, on the other hand, are more suitable for metal cutting and marking applications.

Service Life: CO2 laser cutting machines use an air generator to excite the laser, which has a wavelength of 10.6μm, while fiber laser cutting machines use a solid laser generator to excite the laser, which has a wavelength of 1.08μm. Due to the wavelength of 1.08μm, fiber laser cutting machine can propagate over long distances, and the service life of fiber laser cutting machines is longer than that of CO2 laser tubes.

Loss: CO2 laser generators rely on mirrors to transfer the laser from the oscillator to the processing point. It is necessary to keep the reflector clean and replace such vulnerable parts regularly. On the other hand, fiber is a factor in the functioning of fiber laser cutting machines as a light source, so the loss in fiber laser cutting machines is lower.

Operating Costs: Due to the complexity of components and basic design, the initial cost of fiber laser cutting machines is higher than that of CO2 laser cutting machines. However, in the long run, the maintenance cost of CO2 laser cutting machines is higher than that of fiber laser cutting machines.

Cutting Speed: The advantage of the fiber laser cutting machine's short wavelength allows it to use a more concentrated beam to produce a smaller focus when cutting stainless steel, carbon steel, brass, copper and other metal materials, making the fiber laser more effective in cutting medium-thickness materials. When cutting 6mm thick metal, the cutting speed of the 2kW fiber laser metal cutting machine is equivalent to the cutting speed of the 3kW CO2 laser cutting system.

Precision: CO2 lasers are known for their ability to produce finer details and intricate designs due to their longer wavelength. However, depending on your cutting material needs, if you are using it to process various metals, using a laser metal cutting machine is the industry development trend and your best choice. fiber laser metal cuttin machine has the advantages of high precision, high efficiency, and low cost.

Safety Risks: In the past, CO2 laser cutting machines posed less risk of injury to workers compared to fiber laser cutting machines. However, most fiber laser cutting machines now come equipped with protective covers and smoke and dust removal systems, which have increased safety.

Maintenance Costs and Cycles: CO2 laser generators require maintenance every 4000 hours, while fiber laser cutting machines need maintenance after approximately 20,000 hours.

Cost: CO2 lasers are generally more affordable upfront, making them a popular choice for small businesses or hobbyists. However, the operational costs, including gas refills and maintenance, can be higher. Fiber lasers have a higher initial cost but lower operational expenses.

Opto-electric Conversion Efficiency: The opto-electric conversion efficiency of CO2 laser cutting machines is about 10% to 15%, while the opto-electric conversion efficiency of fiber laser cutting machines is about 35% to 40%. When cutting the same material, fiber laser cutting machines are at least twice as fast as CO2 laser cutting machines. This also means that if someone wants to penetrate such material, CO2 lasers require more electricity.

Environmental Impact: CO2 lasers produce more heat and require a separate cooling system, which can increase energy consumption. Fiber lasers are more energy-efficient and generate less heat, reducing their environmental impact.

Conclusion

CO2 laser cutting machines are widely used in non-metal processing, while fiber laser cutting machines are widely used in the metal industry. Although CO2 laser cutting machines can also cut metal materials, they have been gradually replaced by fiber laser cutting machines in recent years.

The choice between a CO2 laser and a fiber laser depends on your specific needs, including the materials you will be working with, desired cutting speed and precision, maintenance requirements, budget, and environmental considerations. If you primarily work with non-metal materials and require fine details, a CO2 laser cutter may be the better option. However, if you focus on metal cutting applications and prioritize speed and efficiency, a fiber laser cutting machine would be more suitable. It is recommended to evaluate your requirements and consult with laser experts to determine the best choice for your specific application, You can also contact us, Our team will be more than happy to provide you with all the information you need and help you make an informed decision.