10, 2023

by Oree Laser

How to choose the most satisfactory laser welder?

Compared with traditional welding methods, laser welders have become more and more popular in recent years due to their many advantages. This article will share how to choose the most satisfactory laser welder?

First of all, the market for laser welding machine is expected to grow rapidly in the future. This is due to the growing demand for high-precision welding in industries such as automotive, aerospace, electronics, and medical devices. Laser welding is a great choice for these industries because it provides improved weld quality, less distortion, and exact control over the welding process.

Furthermore, the growing demand for efficient and cost-effective welding solutions encourages the use of laser welder. When compared to traditional welding methods, fiber laser welding machine provide faster welding speeds, lower heat input, and lower use of materials. As a result, businesses can improved production and cost savings, increasing demand for laser welding machines.

In addition, technical improvements in fiber laser welding machine is speeding up market expansion. Manufacturers keep developing to improve these machines' capabilities, such as the creation of fiber lasers with more power and improved beam quality. This results in better welding performance and the capacity to work with a wider range of materials.

The market is witnessing a shift towards automation and the seamless integration of handheld laser welder into production lines. This trend is driven by the need for enhanced efficiency, reduced labor costs, and improved quality control. The integration of laser welding machines with CNC systems and other machines enables precise control over the welding process, resulting in seamless operation and accurate welds. This integration also leads to faster production speeds and reduced cycle times, making it particularly beneficial for industries that require high-volume production.

How to choose the most satisfactory fiber laser welder?

To select the most suitable fiber laser welder that meets your specific needs, it is essential to take into account various factors. Here are some crucial aspects to consider:

1. Application: The first step in selecting a laser welder is to determine the specific application for which you need the machine. Different laser welders are designed for different types of materials and applications, so it's essential to choose a welder that is suitable for your needs.

2. Power: The power of a fiber laser welder determines the depth and speed of the weld. Higher power welders are suitable for thicker materials, while lower power welders are ideal for thinner materials.

3. Beam Quality: The quality of the laser beam affects the precision and accuracy of the weld. A laser with a high-quality beam will produce a more precise and consistent weld.

4. Pulse Duration: The pulse duration of the laser affects the heat input into the material. Shorter pulse durations produce less heat, resulting in less distortion and better control of the weld.

5. Ease of Use: A fiber laser welding machine should be easy to operate and maintain. Look for a machine that has a user-friendly interface and requires minimal maintenance.

6. Price: Fiber Laser welders can vary in price, so it's essential to consider your budget when selecting a machine. However, it's important to remember that cheaper machines may not offer the same level of quality and performance as more expensive models.

7. After-sales service: Look for a manufacturer that offers excellent customer support and service. A reliable manufacturer should provide training, technical support, and spare parts when needed. Such as Oree Laser, we are providing training to help our customers understand the operation and maintenance of the fiber laser wedling machine, technical support to address any technical issues or questions that our customers may have, and spare parts and consumables, this ensures that customers can easily replace any worn-out or damaged components to maintain the performance and reliability of the fiber laser welder.

What is a laser welding machine?

A laser welding machine is a powerful and flexible machine that has revolutionized the process of connecting materials. It uses laser technology to create a concentrated controlled beam of high-energy light. This laser beam is directed at the joining materials, forcing them to melt and fuse together.

The ability of laser welding machine to generate welds with exceptional precision and accuracy is its primary benefit. The laser beam's focus enables the fabrication of small and deep welds, resulting in reliable and strong joints. This level of precision is helpful in industries where advanced and delicate components must be connected, such as electronics production.

The adaptability of fiber laser welder is also notable. They can weld an extensive range of materials, including metals. Because of this adaptability, laser welder are in high demand in industries such as automotive and aerospace, where varied materials must be flawlessly joined together.

Additionally, Fiber laser welding machine have a number of advantages over traditional welding methods. In laser welding, the heat-affected zone, or the area surrounding the weld, is significantly smaller, reducing the danger of distortion or damage to the surrounding material. In addition, because laser welding is non-contact, there is no need for a physical contact with the workpiece, which reduces the possibility of contamination or damage to delicate surfaces.

Laser welding machines are known for their speed and productivity when it comes to efficiency. The high-energy laser beam allows rapid welding, resulting in higher production rates. Also, laser welder easily integrate into automated processes, increasing productivity and decreasing cost of labor.

Therefore, a fiber Laser Welder is a cutting-edge tool that uses laser technology to fuse materials precisely and efficiently. Its versatility, accuracy, and capacity to generate high-quality welds make it a vital tool in a wide range of industries, allowing the construction of complicated and long-lasting products.

What is the advantage of 3 in 1 laser welding machine?

Are you looking for a multifunctional tool that can weld, clean and cut? Orelaser 3-in-1 handheld laser welding machine is your best choice!

This blog will tell you what the functions of a 3-in-1 laser welding machine are. If you are interested in three-in-one laser welding machine, please feel free to contact us.

1. Versatility: A 3-in-1 laser welder combines three different welding processes - laser welding, laser cutting, and laser cleaning- into a single machine. This allows for a wide range of applications and the ability to perform various welding tasks with just one machine.

2. Time and cost-saving: With a 3-in-1 laser welding machine, there is no need to invest in separate machines for different welding processes. This saves both time and money on equipment purchases and maintenance.

3. Increased productivity: The ability to perform multiple welding processes with one machine increases productivity. There is no need to switch between different machines or set up separate workstations, resulting in faster turnaround times and higher efficiency.

4. Precision and accuracy: Laser welding technology offers high precision and accuracy, ensuring clean and precise welds. The 3-in-1 laser welding machine allows for precise control over the welding, cutting, and cleaning processes, resulting in high-quality and consistent results.

5. Flexibility: The 3-in-1 laser welding machine can be easily adjusted and programmed to accommodate different welding tasks and materials. This flexibility allows for customization and adaptability to various production needs.

6. Reduced heat-affected zone: Laser welding produces a smaller heat-affected zone compared to traditional welding methods. This minimizes distortion and damage to the surrounding material, resulting in stronger and more durable welds.

7. Enhanced safety features: 3-in-1 laser welding machines are equipped with advanced safety features, such as protective enclosures and laser beam shielding. This ensures the safety of the operator and reduces the risk of accidents.

8. Easy operation and maintenance: Most 3-in-1 laser welders are designed to be user-friendly, with intelligent control system and easy maintenance procedures. This reduces the learning curve for operators and simplifies the overall operation and maintenance of the machine.

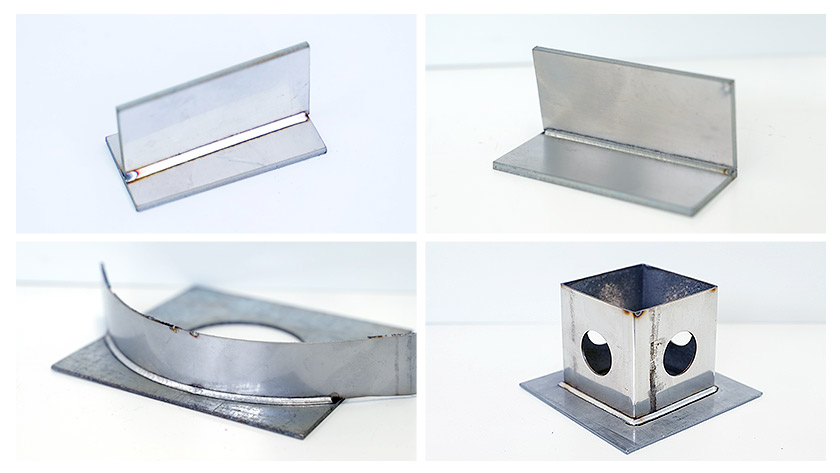

How thick can a laser welder weld?

The thickness that a laser welder can effectively weld is affected by a variety of factors, including the type of material being welded, the laser's power, and the exact welding setup. Laser welders, on the other hand, generally weld materials ranging from very thin sheets to thicker components.

Oree Laser welding machine can weld stainless steel and carbon steel with different thicknesses of 1mm, 2mm, 3mm, 4mm, 5mm, can weld up to 8mm, The optimal welding thickness is 3mm.

Oree Laser's hot-selling models now include power options of 1500w, 2000w, 3000w, please feel free to contact us.

Laser welders can achieve welds as thin as a fraction of a millimeter for thin materials such as foils or thin sheets. This is made possible by the laser beam's precise control and concentrated heat.

The maximum thickness that a laser welder can manage for thicker parts is determined by the power and capability of the given laser system. However, as the thickness of the weld rises, the welding process might require additional passes or changes to achieve appropriate penetration and weld quality.

It is essential to remember that the specific capabilities and limitations of a laser welder should be determined by reviewing the manufacturer's specifications or by conducting tests on the materials and thicknesses you need to weld.

The depth of laser welding is determined by material properties such as thickness. Carbon steel and titanium require distinct welding settings, hence the same parameters cannot be used for both.

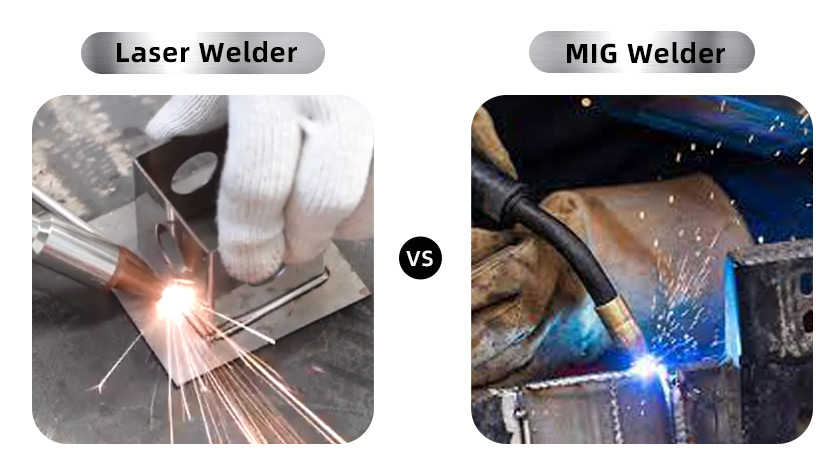

Are laser welders better than MIG?

Laser welders are better to MIG (Metal Inert Gas) welders depending on the application and requirements. Fiber Laser welder provide various advantages over MIG welders, including increased precision, faster welding speeds, and the ability to weld a wider variety of materials. When compared to MIG welding, laser welding creates a smaller heat-affected zone and less distortion. MIG welding, on the other hand, may be more suitable for some purposes, such as welding thicker materials or in cases where cost is a considerable concern.

Laser welders are widely considered to be better to MIG (Metal Inert Gas) welders in multiple ways:

1. Precision and accuracy: Because of highly focused laser beams, laser welder machine provide exceptional precision and accuracy. When compared to MIG welding, this provides for more exact control over the welding process, resulting in cleaner and more accurate welds.

2. Speed: MIG welders are slower than laser welders. Because the laser beam can rapidly heat and melt the metal, welding times are reduced. This improved speed might result in increased productivity and lower production costs.

3. Heat input and deformation: When compared to MIG welding, fiber laser welder create less heat input and distortion. The laser beam's focus reduces the heat-affected zone, lowering the danger of warping or distortion in the welded material. This is especially useful when dealing with delicate or heat-sensitive materials.

4. Versatility: Laser welding machine is extremely versatile and can weld a variety of materials, such as carbon steel, stainless steel, aluminium, etc.

5. Automation and integration: Metal Laser welders can easily integrate into automated production lines, allowing efficient and continuous welding processes. Although automated systems exist, MIG welding might require more manual participation and setup.

In general, laser welders outperform MIG welders when it comes to of precision, speed, heat input, and flexibility. Because of these benefits, laser welding is an excellent solution for a variety of industries, including automotive, aerospace, electronics, and medical device manufacture.

How much does a fiber laser welding cost?

The cost of a fiber laser welding machine can vary depending on several factors, including the power of the laser, the size and capabilities of the machine, and the specific requirements of the application. Generally, The price of fiber laser welding machine is about several thousand dollars. It is recommended to contact manufacturers or suppliers directly to get accurate pricing information based on your specific needs.

About Oreelaser laser welding machine

Oreelaser offers a wide range of laser welding machines, including the fully automatic OR-WT platform laser welding machine. This innovative machine has a double swing laser welding head that allows for continuous precision laser welding as well as laser spot welding. It provides outstanding welding performance due to its high welding strength, exceptional accuracy, and quick speed.

A CNC three-axis moving table (XYZ) controlled by computer programs is also included in the OR-WT machine. This allows for geometric space movement, making it suitable for welding a wide range of product forms and sizes. The equipment can follow any welding path with ease, delivering precise and efficient welding. It also has 360° welding capabilities and can be used for automatic or semi-automatic electric welding. This machine produces welds that are not only visually appealing but also sturdy. Furthermore, the machine is rapid, requires no consumables, has minimal workpiece deformation, and removes the need for post-welding grinding.

The OR-HW-B, a water-cooled handheld laser welder by Oreelaser, is another important laser welding machine. This laser welder allows for flexible processing and effective welding. It's portable and has a tiny footprint, making it suitable for welding small-sized workpieces. The OR-HW-B reaches welding speeds that are 3-10 times faster than typical argon arc and plasma welding. It has a professional welding system and is simple to use, allowing for one-time shaping of workpieces and more efficient welding. A CNC three-axis movable table (XYZ) is also included for precision movement and positioning.

Oreelaser provides the OR-HW-C for individuals looking for a compact and effective welding option. This water-cooled handheld welding machine is built for versatility and efficiency. It has a dual-drive handheld swing laser welding head that ensures precise and consistent welding performance. The machine includes a basic operation panel that makes it easy to use. It also includes a dual temperature and dual control water cooler, which provides rapid cooling for the internal pipeline cavity of the welding head as well as the laser. Furthermore, the equipment comes with a standard 10-meter optical fiber, allowing for 360° no dead angle micro welding.

Finally, the OR-HW-D, a water-cooled portable welding machine. This flexible machine provides variable processing and effective welding capabilities. It comes with a professional welding technology that offers high-quality welds. The equipment is simple to use and enables for one-time forming of workpieces, which results in more efficient welding. It, like earlier models, has a CNC three-axis movable table (XYZ) for precise movement and positioning.

If you are interested in learning more about our laser welding machines or have any inquiries, please don't hesitate to contact us.