10, 2018

by oreelaser

Pipe laser cutting machine is also called steel tube laser cutting machine. Compared with the small laser cutting machine, tube laser cutting machine is specially used to cut some metal steel pipes with a certain thickness. We all know that it is difficult to cut the metal and it requires the laser cutting machine with a large power and processing width. The laser tube of the tube laser cutting machine adopts a gemstone laser tube imported from abroad with a good cutting ability and strong absorption ability to the metal. Therefore, for the cutting of metal steel pipes, the tube laser cutting machine is an indispensable tool.

In the past, metal pipe laser cutting machine’s processing was limited to the cutting level, and there were not many complicated processing requirements. However, as the market demand became more diverse, the requirements for pipe cutting became higher and higher. The traditional cutting method can also achieve the application effect, but the processing efficiency is low and the processing effect is poor. In order to meet the diversified market demand of the industry, various tube laser cutting machines have received the attention of users, and was used by more and more metal processing industry users. With the advantage of the professional, stable and efficient cutting effect of the tube laser cutting machine to meet the cutting needs of users. Therefore, the combination of pipe cutting and laser technology will have a broader development prospect in the field of pipe cutting. So what is the future development trend of tube laser cutting machine? Oree laser will take you into the future world of tube laser cutting machine.

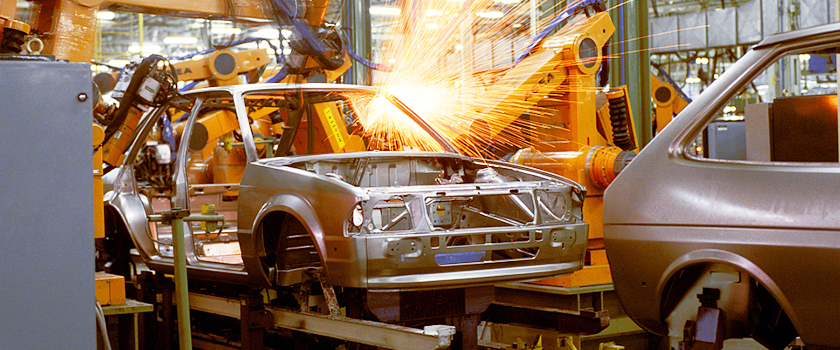

The tube laser cutting machine is a professional laser cutting machine for pipes and tubes. It has advantages over other cutting equipment in cutting pipes. It can cut efficiently and accurately for any shaped pipe. Pipe laser cutting machine quickly occupied various metal processing industries with its professional and stable cutting effect, especially in automobile manufacturing, oil exploitation, machinery manufacturing and so on.

The tube laser cutting machine adopts non-contact processing method, and does not exert any pressure on the pipe wall of the pipe during the whole process, so it will not cause deformation or collapse of the outer surface of the pipe. At the same time, when the laser cutting machine processes the pipe, the cutting hot field is complicated, the cooling is difficult, and the cutting slag is easy to block, which makes the cutting difficulty more difficult. Therefore, it is necessary to strengthen the in-depth study of these aspects.

Laser cutting requires a lot of freedom in the pipe material, shape, size, processing environment, etc. Like its excellent spatial control (beam direction change, rotation, scanning, etc.) and time control (on, off, pulse interval), easy to control, besides that laser cutting has high precision and less burrs, it greatly reduces the time spent on subsequent processing. When changing the diameter or shape of the pipe, it is only necessary to modify the program, so the development of the pipe cutting software is of great research value. The combination of laser cutting system and computer numerical control technology can form an efficient automation equipment, opening up a new path for high quality, high efficiency and low cost processing.

In order to improve the efficiency of pipe cutting, it is the most effective production method to use the pipe laser cutting automatic production line. How to use the pipe cutting automatic production line for laser cutting? Firstly, the laser beam after focusing must be guaranteed to run synchronously with the pipe being cut on the automatic pipe cutting line; secondly, the laser focus after focusing is required to rotate one revolution relative to the pipe being cut, and the laser beam axis is always perpendicular to the axis of the pipe. Intersecting, during the cutting process, the laser beam of the tube cutting line follows the cut tube. These synchronous movements must be controlled by a special control system, so the research on the automatic laser cutting line production line is also very important.

The future development trend of pipe laser cutting machine: In terms of the market demand of pipe laser cutting machine, with the continuous development of industry, the demand for pipe laser cutting machine is also rising, and under the leadership of international advanced technology, it is rising at a high speed. And the technology and related applications of tube laser cutting machines are increasingly being valued by many experts and related companies.

Professional Laser Cutting Machine Manufacturer - OreeLaser