09, 2018

by Ada liu

Fiber laser cutting machine is a new type of cutting machine newly invented in the international market in recent years. This cutting machine has an absolute advantage in both cutting speed and mechanical volume. Today we will talk about the advantages of fiber laser cutting machines and their application range and industry.

Firstly, let’s know the advantages of the fiber laser cutting machine.

Advanced cutting technology

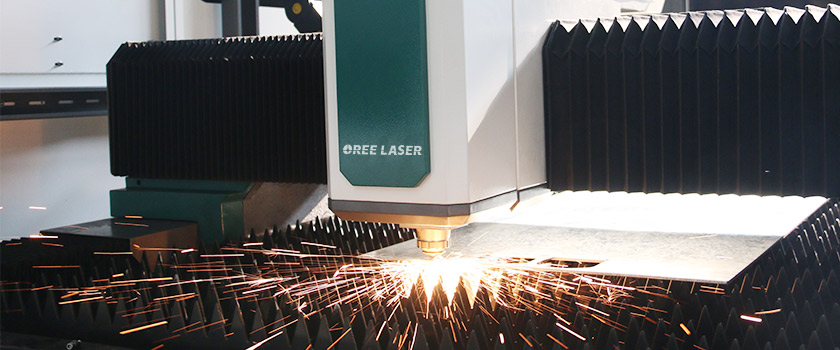

The fiber laser cutting machine adopts a high-performance laser cutter as its cutting principle. During the cutting process, the laser emits numerous high-performance, high-energy laser rays, and the cut surface can be vaporized in an instant with the huge energy generated by these laser rays. So that a very hard interface can be easily removed. At present, this process is also a state-of-the-art cutting process. No other cutting process can surpass it. Moreover, this cutting process is very fast during the cutting process, and it can cut the very thick steel plate easily and cut it in an instant. The accuracy is also very accurate, the cross-section accuracy of the cutting can reach a few millimeters, which can meet some high-demand cutting requirements.

Stable cutting performance

This fiber laser cutter adopts an extremely stable world-class laser during the cutting process. And the life of this laser will last for several years. That is to say that there will hardly any failure of the system itself except for human factors in the process of use. Even if this laser cutting machine is under long working pressure, it will not produce any vibration or other adverse effects.

Convenient mechanical operation

In the process of using the fiber laser cutting machine, all information transmission and energy propagation are transmitted through the optical fiber. The biggest advantage of transmitting in this way is that it saves a lot of manpower and material resources, and there any optical path leakage will occur during the transmission process. In addition, you can easily transfer energy to the laser without making any adjustments to the light path before using the device.

Small size of the machine itself

This laser cutter has only one core component called a laser that emits laser light. And the laser is very compact in size, which does not occupy a lot of space like other cutting equipment’s of the same type, so that the overall volume of the machine is reduced. With the smaller volume, whether it is in the process of mechanical production or transportation, we can reduce a lot of human and material resources for us.

Thanks to the high speed and flexible cutting of the laser cutting machine, many complex graphics can be quickly formed, which is very popular among enterprises. As long as the customer wants, after the CAD is made, the relevant materials can be directly cut out, and there is no problem in customization. So which industries can 3000W fiber laser cutting machines be used in?

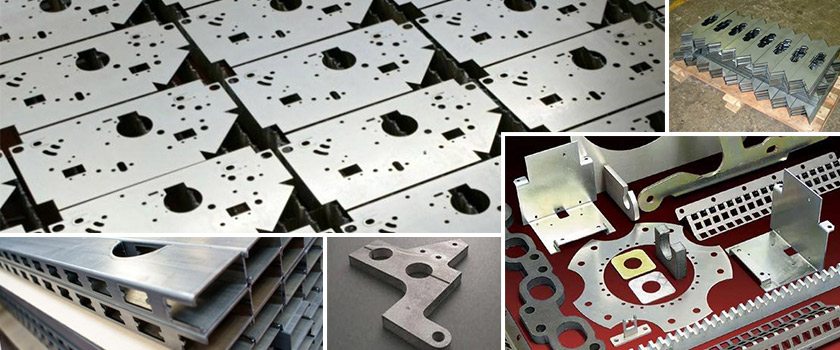

1.The automotive industry. Many corners of the automobile industry, such as automobile doors and automobile exhaust pipes, need to be processed after the formation of some extra corners or burrs. If by other cutting methods, firstly the precision is difficult to achieve, and the efficiency is another problem. The fiber laser cutting machine with the advantages of good cutting quality and precision, is suitable for the automotive industry.

2.Advertising industry. Due to the high speed and flexible cutting of the laser cutting machine, many complex graphics can be quickly formed, which is very popular among the advertising industry. As long as the customer wants, after the CAD is made, the relevant materials can be directly cut out, and there is no problem in customization. In addition, there are more customized products in the advertising industry, and the traditional method is very inefficient. The laser cutting machine is very suitable for the industry.

3.Kitchenware industry. Nowadays, there are more and more new houses, which all need decoration, and the demand for kitchen-related products is getting bigger and bigger. The laser cutting machine is suitable for cutting thin-plate stainless steel, with the features like high speed, high precision, and can realize customized and personalized product development, won the kitchen manufacturers love.

4.Sheet metal industry. For sheet metal processing companies, the processing of sheet metal materials is essential. Simply put, it is a variety of plates, a variety of different graphic cutting parts. Before the advent of laser cutting machines, large-scale cutting machines were generally used for cutting, in which the processed materials were not high in precision and the cost was high. However, after the appearance of the laser cutting machine, the production efficiency was greatly improved. Therefore, the development of laser cutting machines in this industry is in full swing.

5. Fitness Equipment industry. Due to the state's emphasis on sports health and the development of personal health concepts. Square fitness equipment and home fitness equipment have gradually developed, and the demand is gradually increasing. There are basically some pipe cutting, it is convenient and quick to use the pipe fiber laser cutting machine to cut the pipes.

Professional Laser Cutting Machine Manufacturer - OreeLaser