02, 2019

by oreelaser

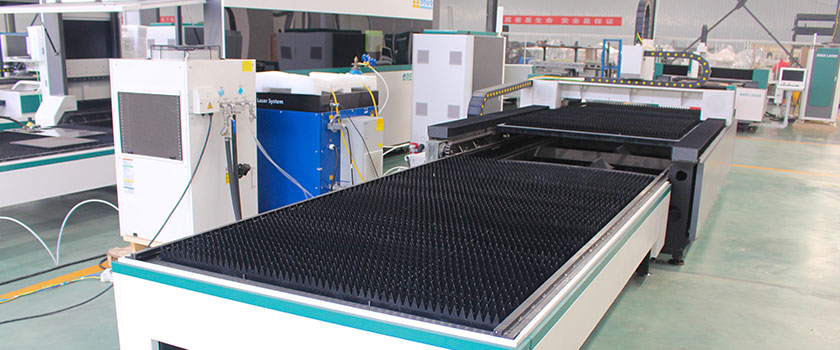

Metal laser cutting machine is a high-tech product invented in the era of rapid industrialization. Its advanced technology and processing technology have been widely used in various industries. The birth of laser cutting machine has laid the foundation for industrial development. However, when using a metal laser cutting machine, many operators will find that the metal laser cutting machine occasionally heats up too fast. And we all know that water plays a key role in the metal laser cutting machine. Then, what are the reasons for the water temperature of the metal laser cutting machine rises rapidly?

1.When the metal laser cutting machine is operated, the surrounding ambient temperature is high.

2. Metal laser cutting machine works too much.

3.The metal laser cutting machine has worked a long time, so it is necessary to stop the machine properly.

4.The outlet pipe of the cooling water is not flowing properly, resulting in a smooth flow of water.

5.The water inlet and outlet pipes of the pump are dirty, and the water pipe is blocked, which makes the water flow poor.

All of the above are the reasons why the water temperature of the metal laser cutting machine rises rapidly. In fact, it is very simple to troubleshoot these abnormalities, and is not troublesome to operate.

The following is a solution to the high temperature of the laser cutting machine:

As we all know that the laser cutting machine needs a lot of water to cool the high temperature inside the laser tube to ensure the normal use and service life of the laser tube. However, when the laser cutting machine is used normally, the water inside the cooling water tank is easy to happen that the water temperature is too high, especially in summer, it takes less than 2 hours to heat up. If it is not replaced in time, the power of the laser tube will drop significantly. Then the cold water device is particularly important. The chiller of the laser cutting machine must be regularly maintain, in order to ensure that the machine is in good condition. If you encounter a fault, remember not to dispose of it yourself. You should ask a professional technician to repair it. Do not disassemble the machine yourself.

Daily maintenance of laser cutting machine chillers should pay attention to the following aspects:

1. Regularly clean the heat sink. The cleaning method is as follows: brush the heat sink carefully with a brush, then blow it off with compressed air. If necessary, clean and rinse with special air conditioner fin cleaning agent.

2. Dust off the condenser regularly (the method is the same as above).

3. Regularly check the water level in the water tank of the chiller. If the water level is too low, add pure water or deionized water in time.

4. Regularly check the terminals of the appliance and remove the dust (after the power is off).

5. Regularly check whether the joints in the waterway system are leaking, whether the pipeline is aging, and if there is water leakage, replace the relevant components in time.

6. Regularly check the water quality in the water tank of the chiller. If the water quality of the cooling water becomes worse, turbid, and the transparency is reduced, it is necessary to discharge all the deteriorated cooling water in time and replace the new cooling water.

7. Regularly clean the impurities on the filter element. If the filter element is damaged, it should be replaced in time.

If you have other questions about the metal laser cutting machine, you can consult our technical staff. Oree laser always focuses on the enterprise spirit of “We are committed to provide the users with the comprehensive laser application solutions around the world. In the "customer first" principle will always serve you wholeheartedly.

Professional Laser Cutting Machine Manufacturer - OreeLaser