02, 2020

by Oree Laser

Hand-held laser welding machine generally consists of laser, chiller, control software, laser welding head, optical fiber and other components. It has the advantages of small size, easy operation and strong functionality.

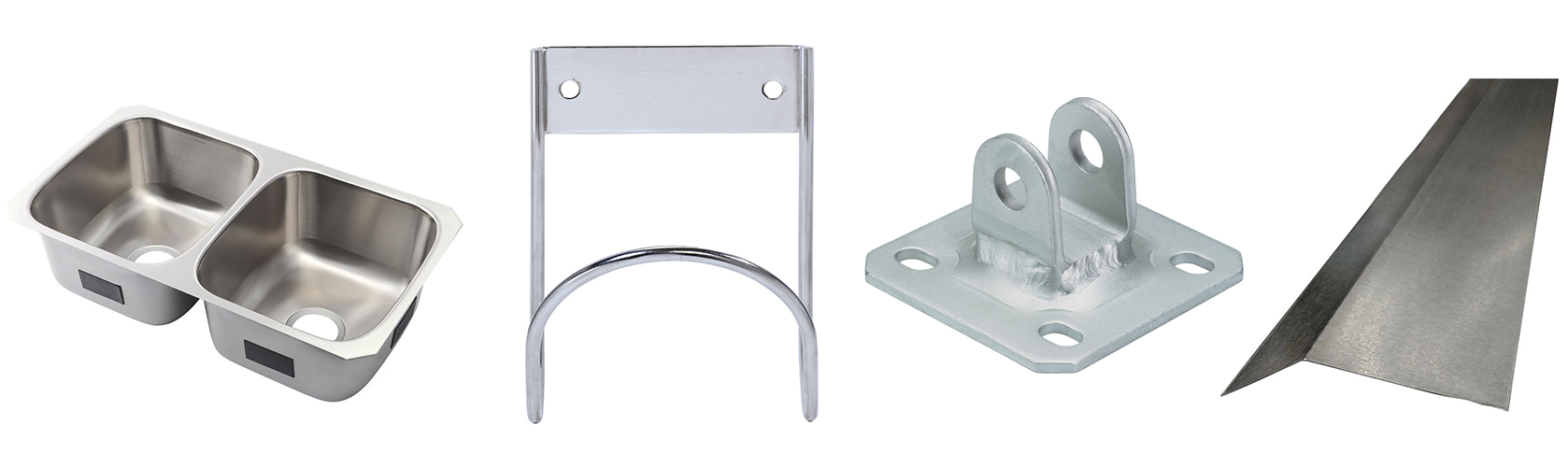

The hand-held laser welding machine fills the blank of hand-held welding in the laser equipment industry. The hand-held laser welding machine has overturned the working mode of the previous laser welding machine and replaced the fixed light path with the hand-held welding gun. This mode of operation is not only more convenient for welding molds, advertising characters, kitchenware, doors and windows and other products, but also makes laser welding possible outdoors.

Oree hand-held laser welding machine OR-HW, using the latest continuous fiber laser and high-quality welding head, is a revolutionary breakthrough in welding technology. It is especially suitable for welding stainless steel, carbon steel, galvanized sheet, copper sheet, aluminum and other metal materials. It can perfectly replace the traditional argon arc welding and electric welding.

The operating mode of the handheld welding torch can realize arbitrary 360 ° welding of the workpiece, which is suitable for the welding of various complex welds and various devices.

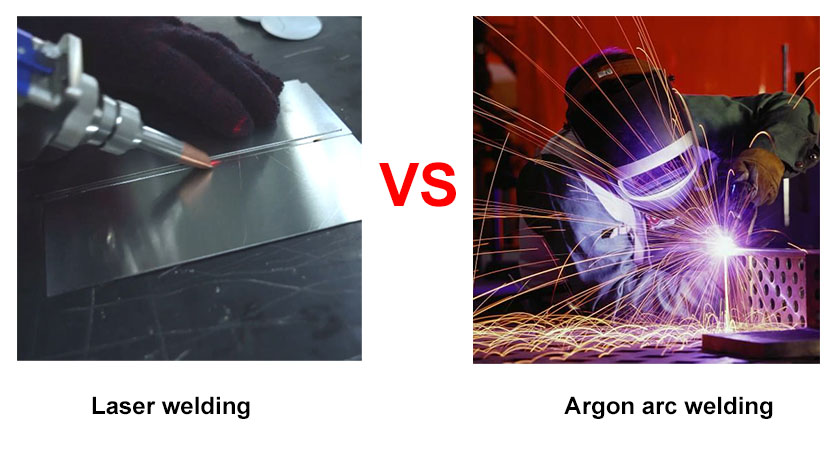

Advantage comparison:

● Fast welding speed, 2-10 times faster than traditional welding. One machine can save at least 2 welders a year.

● Easy to operate, you can work without a job permit, and you can weld beautiful products without skilled technicians.

● The welding seam is smooth and beautiful, reducing the subsequent grinding process, saving time and cost.

Welding manner | Heat affected zone | Thermal deformation | Welding quality | Whether to add solder | Subsequent processing | Welding speed | Operator safety |

Argon arc welding | Larger | Larger | general | Yes | Need to be polished | slower | Unsafe |

Laser welding | Smaller | Smaller | better | No | No need | Faster | Safety |

Traditional process stainless steel welding uses argon arc welding, but there are many defects in argon arc welding, which is very unsatisfactory in terms of aesthetics and welding efficiency. Laser welding is not only efficient, but the product is not deformed. No subsequent processing is required, and one hand-held laser welding machine is equivalent to ten argon arc welds.

Professional Laser Cutting Machine Manufacturer - OreeLaser