07, 2020

by Oree Laser

The problems of "time-consuming and labour-intensive" brought about by the traditional welding process technology have long been difficult to meet the improvement of welding flexibility and precision processing requirements in the field of sheet metal processing.

The emergence of hand-held laser welding has effectively solved the complex and irregular welding process of the kitchen cabinets, staircase elevators, shelves, ovens, stainless steel door and window guardrails, power distribution boxes, stainless steel home furnishing and other industries.

● Product Introduction

For production workshops engaged in small-scale processing or non-large-scale welding, hand-held welding machines are the best choice, occupying small space and diversifying welding products. The handheld laser welding machine uses a handheld welding gun to replace the previously fixed optical path, subverting the previous working mode of the laser welding machine. This mode of operation is not only convenient for welding moulds, advertising words, kitchenware and other products, but also for outdoor laser welding.

● Features of handheld laser welding machine

1. The hand-held welding head is flexible and convenient, which can realize outdoor welding.

2. The operating mode of the hand-held welding machine enables the workpiece to be welded at any angle at any location.

3. It is suitable for spot welding of various complicated welding joints and various equipment.

● Application range of handheld laser welding machine

Widely used in kitchens, household appliances, advertising, moulds, stainless steel doors and windows, crafts, household items, furniture, auto parts and many other industries.

● OREELASER hand-held laser welding machine OR-HW

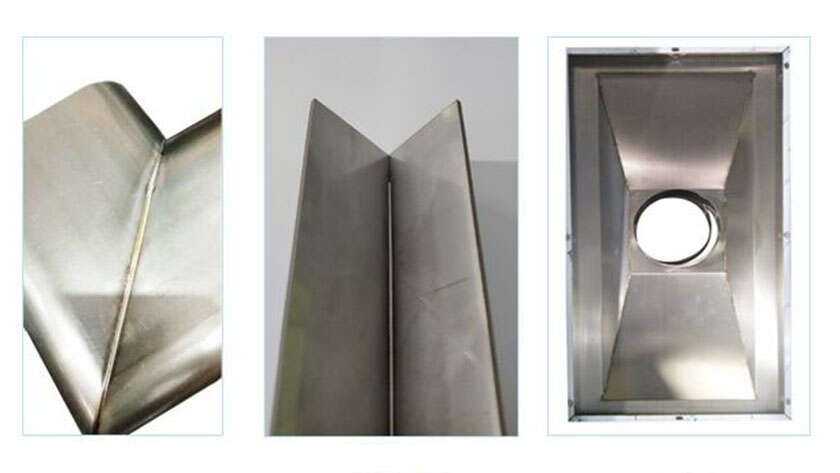

OREE laser hand-held fiber laser welding machine adopts the latest generation of fiber laser and is equipped with an intelligent laser welding head. It has many advantages such as simple operation, beautiful welding line, fast welding speed and no consumables. Welding applications in metal materials such as thin stainless steel plates, carbon steel plates, and galvanized sheets can perfectly replace traditional argon arc welding and electric welding. Hand-held laser welding machine can be widely used in kitchen cabinets, stair elevators, shelves, ovens, stainless steel door and window guardrails, distribution boxes, stainless steel home and other industries.

● Advantages of Handheld Laser Welding

1. Improve process defects: Hand-held laser welding can improve welding defects such as undercut, under-welding, dense pores and cracks in the traditional welding process.

2. Good welding effect: fast welding speed, smooth and beautiful weld after welding. When welding, the heat affected area is small, which will not cause work deformation, blackening, and trace problems on the back. Moreover, the welding depth is large, the welding is firm, and the melting is sufficient.

3. Cost-saving: good welding effect reduces subsequent grinding process, saving time and cost (2-10 times faster than traditional welding, a machine can save at least 2 welders a year and fewer consumables). Fewer consumables, long life and low equipment maintenance costs.

4. Simple operation: welding by hand, quick start, flexible and convenient, and longer welding distance.

5. High flexibility: suitable for all kinds of complex welds, easy to weld any part of the workpiece at any angle. Further, broaden the scope of application of laser welding.

● Limitations of handheld laser welding

Handheld laser welding machine: It needs to be held by the user, and long-term work will cause fatigue, cause labour loss, and is not conducive to the welding of large components.

Use safety issues: First, the welder must undergo strict training, the laser can not hit people or surrounding objects, otherwise, it will cause serious burns or even fire; second, although the welding process is directed at the workpiece, it will produce high-brightness reflections, the long-term operation will affect the eyes.

● Operating mode

1. Working principle: Laser welding is non-contact welding. No pressure is required during the operation. The laser beam of high energy intensity is directly irradiated on the surface of the material. Through the interaction of the laser and the material, the inside of the material is melted, and then the crystal is cooled to form a weld seam.

2. Operation mode: Hand welding, easy to operate.

3. Use characteristics: According to the different ways of use, laser welding machines are divided into handheld laser welding machines and desktop laser welding machines. Compared with the desktop laser welding machine, the handheld fibre laser welding machine is mainly for laser welding of long-distance and large workpieces. Welding on thin stainless steel plate, iron plate, galvanized plate and other metal materials can perfectly replace the traditional argon arc welding, electric welding and other processes.

Professional Laser Cutting Machine Manufacturer - OreeLaser