09, 2023

by OREE LASER

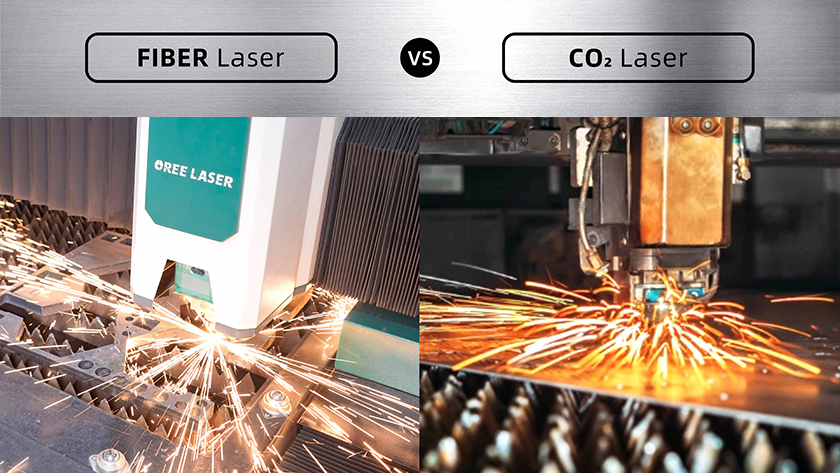

A laser cutting machine is a type of machine that uses a high-power laser beam to precisely cut materials. Fiber laser cutting machine works by directing a laser beam onto the surface of a material, causing it to melt, burn or vaporize, resulting in clean, precise cuts. Metal Laser cutting machines are widely used in various industries and can cut a variety of materials, such as stainless steel, carbon steel, iron, brass, aluminum, etc.

1.1 Advantages Of Fiber Laser Cutting

-Precision

Fibre laser cutting offers unrivaled performance in metal fabrication, and its precision and accuracy result in optimal output figures. This guarantees exceptional precision and the ability to perfectly reproduce complex designs, even those that are challenging for traditional cutting methods. In addition, laser cutting minimizes the thermal impact on the material, ensuring that the metal is not deformed and of high quality. As a result, High power output and beam quality, which create a cleaner cutting edge.

-Speed

Due to the advancement of modern technology, the speed of laser cutting has increased. Contemporary fiber laser cutters exhibit lightning-fast performance. By optimizing the cutting process, the working time of the laser cutting machine is significantly reduced, while still delivering the highest quality and precision. Works at a faster speed than CO2 lasers, increasing overall efficiency. Moreover, operating the machine is incredibly convenient and requires minimal preparation. All that is needed is a design and appropriate calibration, making laser cutting a hassle-free and efficient option.

-Consistency

The complete automation of the laser cutting process ensures impeccable consistency in movements. No room for error or inaccuracies that may arise when the device is manually operated by a human. The utilization of a laser plotter for metal opens up immense possibilities for working on intricate and highly detailed projects. Lower power consumption keeps running costs low. Furthermore, the laser beam's trajectory is continuously adjusted by the machine itself, eliminating errors and minimizing material wastage. This level of consistency ensures optimal results and minimizes any potential variations.

1.2 Disadvantages of Fiber Laser Cutting

Although fiber laser cutting machines have become very advanced, they are still not perfect and have their own set of shortcomings. If you have any questions about the machine when purchasing a laser cutting machine, you can always consult us and we can help you determine whether a fiber laser cutting machine is suitable for your workshop.

-Fiber laser cutting machines and their components are expensive to purchase, and as you can imagine, fiber laser cutting machines are quite expensive due to their high precision and efficiency

-Compared with CO2 laser cutting machine, fiber laser cutting machine can only cut metal, not non-metal

But despite this and some other disadvantages, fiber laser cutting still has greater advantages. With the development of technology, all the shortcomings of fiber laser cutting are likely to be solved and improved slowly.

Fiber laser cutting machines are advanced tools used for accurately cutting materials like carbon steel, stainless steel, iron, aluminum, brass, and more. They are commonly used in industries such as manufacturing, automotive, aerospace, electronics, etc. These laser cutting machines utilize a powerful laser beam to melt, burn, or vaporize the material, resulting in precise and clean cuts. They are known for their fast cutting speed, ability to handle complex designs, and their ability to cut with great accuracy.

-Automotive industry: Metal laser cutter are used to cut body panels, chassis components, and exhaust systems with utmost precision.

-Aerospace industry: Fiber laser cutter for cutting materials like aluminum, titanium, and composites to create complex and lightweight aircraft components.

-Electronics industry: Metal laser cutting machines are used to cut circuit boards, microelectronics, and other electronic components with high precision.

Overall, fiber laser cutting machines are highly regarded for their exceptional precision, fast cutting speed, and ability to handle a wide range of materials. They play a vital role in various industries by enabling the production of high-quality components and products with utmost accuracy and efficiency.

The cost of a metal laser cutter depending on several factors. The main factors affecting the price:

Different types of metal laser cutting machines: Such as CO2 laser cutters and fiber laser cutters. CO2 laser cutters are generally more affordable compared to fiber laser cutters, which are known for their high cutting precision and efficiency.

The power of the machine: Higher power laser cutters are capable of cutting through thicker plates with ease. If you have specific requirements for cutting thick plates, a high-power fiber laser cutting machine would be necessary, but it would also come with a higher price tag. On the other hand, if you don't have stringent requirements for cutting precision and mainly need to work with thinner materials, an ordinary cutting machine with lower power would be a suitable and more cost-effective choice.

Features and capabilities: Some models may come with advanced features like automatic material feeding systems or enhanced cutting speed, which can drive up the price. However, if you have simpler cutting needs and don't require these additional features, opting for a basic model can help keep the cost down.

It is important to carefully assess your cutting requirements and budget in order to choose the most suitable machine that meets your needs.

For more information about the machine, we will continue to update. If you have any inquiries regarding the price, videos, or machine details, please feel free to contact us.