12, 2019

by Oree Laser

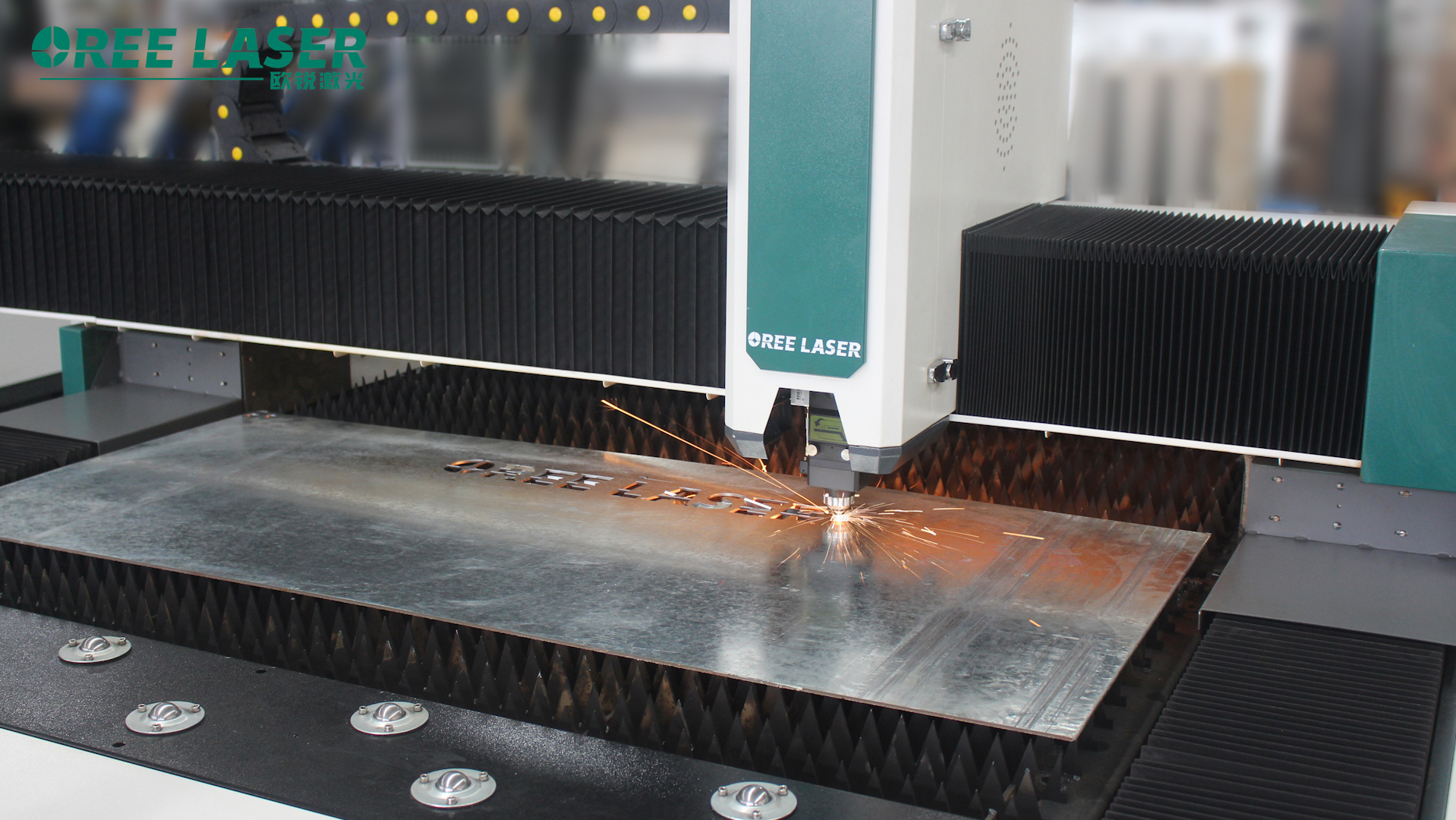

In the process of laser processing of the entire board, due to different materials cutting environments, poor processing in local areas often occurs. In general, in order to deal with local failures, the staff will greatly affect the entire production schedule, thereby affecting the efficiency of laser processing.

In view of such problems, a trial cutting and mass production process are needed before being produced or mass-produced in the production process. Therefore, the Oree laser plate cutting process came into being.

Oree whole plate cutting process

The cutting process of Oree’s entire board is divided into two processes: trial knife and mass production. The test knife generally chooses a round square for cutting. Generally, the size of the round square is not strictly required, but the deviation between the actual size and cut size must be determined to compensate for the size during mass production. The main purpose is to check whether the parameters normal cutting, cutting section and cutting size are qualified. It is recommended to select the test knife pattern for the test.

The start point for mass production is set at the lower right of the part. To reduce the error caused by the deformation during the cutting process, it is recommended that the part be 5mm to 10mm away from the edge of the board.

The advantage of Oree laser cutting:

● During the cutting process, there is no need for staff supervision. After the cutting is completed, the machine will automatically send a signal to remind the staff to replace the plate, thereby saving labour and material costs.

● When the tool is tested, the machine will automatically compensate the dimensional deviation to the mass production graphics and complete the batch sheet processing process more intelligently.

● According to the differences in thickness, processing format and processing responsibility of the plate, there are strict size requirements and stable parameters before mass production. The quality of the processed workpiece is high and the practicality is high. It has achieved fast, stable and high-quality processing results.

● The micro-connection of the cutting workpiece during mass production can effectively avoid the workpiece from being warped due to the thermal deformation of the plate during the entire board cutting process, avoid parts overturning, collision, and cutting misalignment, thereby improving the smoothness of the entire board cutting.

The Oree laser whole plate cutting technology solves the problem of plate waste in the whole plate processing process. It is suitable for batch and large-scale automated production, optimizing the entire production process, and greatly improves the production efficiency of laser sheet metal processing.

The continuous innovation and application of Oree laser cutting process technology have made breakthroughs in the problems of slow perforation, slow cutting speed, difficult to cut thick plates, poor cutting section quality, deviation in cutting parameters, easy thermal deformation of plates, and unstable production of the entire plate. Achieve long-term efficient and stable operation of the equipment, and help processors improve efficiency and add value.

Professional Laser Cutting Machine Manufacturer - OreeLaser