09, 2020

by Oree Laser

The relationship between nozzle and cutting quality

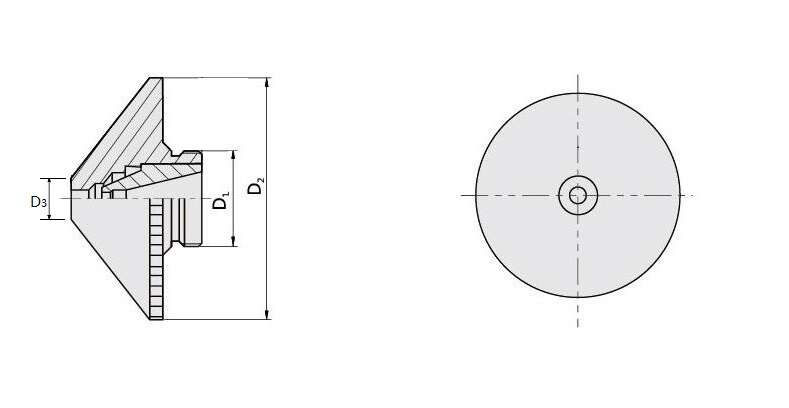

When the nozzle center and the laser center are not on the same axis, the effect on cutting quality:

1) Affect the cutting section. When the cutting gas is sprayed, it will cause uneven air volume, which makes it easier for the cutting section to have melting stains on one side and not on the other side. It has little effect on cutting thin plates below 3mm. When cutting a sheet of more than 3mm, its impact is more serious, and sometimes it will not be able to cut.

2) Affect the quality of sharp corners. When cutting workpieces with sharp corners or small angles, it is easy to produce local overmelting. When cutting thick plates, it may not be possible to cut.

3) Affect perforation, instability during perforation, time is not easy to control, penetration of thick plates will cause overmelting, and penetration conditions are not easy to grasp, and the impact on perforation of thin plates is small.

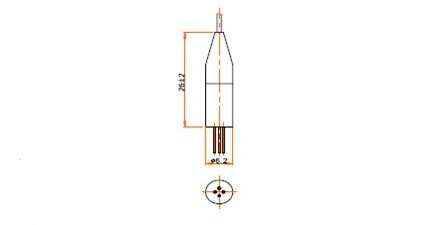

How to choose the nozzle aperture

There are several types of nozzle apertures: φ1.0mm, φ1.5mm, φ2.0mm, φ2.5mm, φ3.0mm, etc. At present, two kinds of nozzle apertures are φ1.5mm and φ2mm. The difference between the two is:

1) Thin plates below 3mm: use φ1.5mm, the cutting surface will be thin; use φ2mm, the cutting surface will be thicker, and the corners are prone to melting stains.

2) Thick plates above 3mm: Due to the higher cutting power, the relative heat dissipation time is longer, and the relative cutting time also increases. With φ1.5mm, the gas diffusion area is small, so it is not stable when used, but it is basically usable. With φ2mm, the gas diffusion area is large and the gas flow rate is slow, so the cutting is more stable.

3) The hole diameter of φ2.5mm can only be used for cutting thick plates over 10mm. In summary, the size of the nozzle aperture has a serious impact on cutting quality and perforation quality. At present, laser cutting mostly uses nozzles with φ1.5mm and φ2mm apertures. Therefore, when the nozzle aperture is larger, the relative protection of the focusing lens is worse, because the sparks of the melt splash during cutting and the probability of bouncing upward is great, which makes the life of the lens shorter.

The concentricity between the center of the nozzle and the laser is one of the important factors that cause the quality of the cutting, especially when the workpiece is thicker, its influence is greater. Therefore, the concentricity between the nozzle center and the laser must be adjusted to obtain a better cutting section.

Note: When the nozzle is deformed or there are melting stains on the nozzle, its impact on the cutting quality is the same as described above. Therefore, the nozzle should be placed carefully and not scratched to avoid deformation; the melting stains on the nozzle should be cleaned up in time. The quality of the nozzle has high precision requirements during manufacturing, and the correct method is required during installation. If various conditions need to be changed during cutting due to the poor quality of the nozzle, the nozzle should be replaced in time.

Professional Laser Cutting Machine Manufacturer - OreeLaser