12, 2023

by Oree Laser

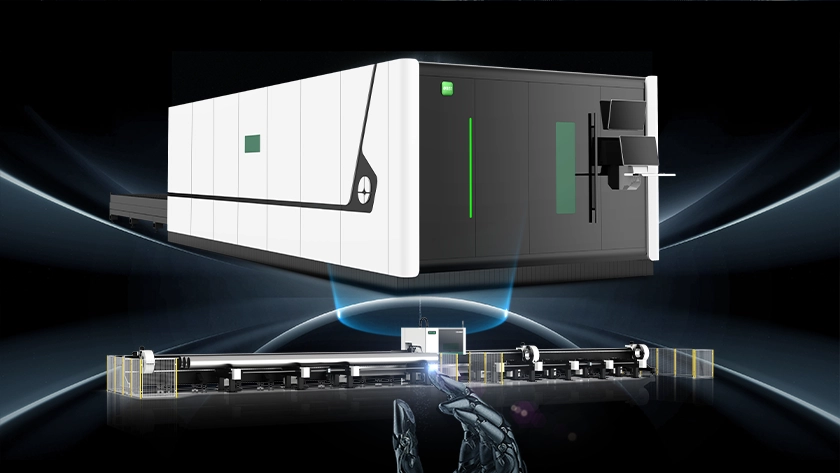

The Future of Fiber Laser Cutting: Trends and Innovations to Watch Out For

Fiber laser cutting machines are a type of laser cutting machine that uses a fiber optic laser to cut through materials. Fiber optic lasers are more efficient and reliable than other types of lasers, and they can cut through a wider range of materials.

Precision and accuracy: Fiber laser cutting machines are capable of producing extremely precise and accurate cuts. This makes them ideal for cutting complex shapes and features.

Speed: Fiber laser cutting machines are very fast. This makes them suitable for large amount production.

Versatility: Fiber laser cutting machines can cut through a wide range of materials. This makes them ideal for a variety of industries, including automotive, aerospace, electronics, and medical devices.

Low operating costs: Fiber laser cutting machines are very energy-efficient and require minimal maintenance. This makes them a cost-effective solution for manufacturing.

Increased productivity: Fiber laser cutting machines can cut parts much faster than traditional cutting methods, which can lead to significant increases in productivity.

Improved quality: Fiber laser cutting machines produce very high-quality cuts, with minimal heat distortion and burrs. This can lead to improved product quality and reduced scrap rates.

Reduced costs: Fiber laser cutting machines are very energy-efficient and require minimal maintenance, which can lead to significant cost savings.

Increased flexibility: Fiber laser cutting machines can cut through a wide range of materials and thicknesses, which gives manufacturers more flexibility in their production processes.

Why Is It Beneficial to Use Parts Cut With a Fiber Laser?

Superior precision and accuracy: Fiber laser cutting machines can produce extremely precise and accurate cuts, with tolerances of up to +/- 0.025 mm. This is essential for many applications, such as the manufacture of medical devices and aerospace components

Smooth and clean edges: Fiber laser cutting produces smooth and clean edges on the cut parts, which reduces the need for secondary finishing operations. This can save time and money

Minimal heat distortion: Fiber laser cutting produces very little heat distortion, which helps to maintain the integrity of the material. This is important for applications where strength and durability are critical.

Wide range of materials: Fiber laser cutting machines can cut through a wide range of materials, This gives manufacturers more flexibility in their design and manufacturing processes.

How to Maximize the Advantages of Laser Technology

To maximize the advantages of laser technology, manufacturers should carefully consider the following factors:

Choose the right laser cutting machine: There are a variety of fiber laser cutting machines available, with different power levels, bed sizes, and features. Manufacturers should choose a machine that is suited to their specific needs.

Use the right cutting parameters: The cutting parameters, such as power, speed, and feed rate, have a significant impact on the quality of the cut. Manufacturers should optimize the cutting parameters for the specific material and thickness they are cutting.

Properly maintain the laser cutting machine: Regular maintenance is essential to ensure optimal performance and reliability. Manufacturers should follow the manufacturer's maintenance recommendations.

Fiber laser cutting has revolutionized the manufacturing industry with its precision, speed, and efficiency. As the technology continues to evolve, here are some trends and innovations to watch out for in the future of fiber laser cutting:

1. Increased Power and Cutting Speeds: Fiber lasers are becoming more powerful, allowing for faster cutting speeds and the ability to cut thicker materials. This trend is expected to continue as manufacturers demand higher productivity and efficiency from their equipment.

2. Automation and Integration: Automation and integration of fiber laser cutting systems with other manufacturing processes are becoming more prevalent. This allows for seamless production and reduces the chances of errors, thus increasing productivity.

3. Improved Cutting Quality: Advancements in fiber laser technology are resulting in improved cutting quality. This includes better edge quality, smoother finishes, and fewer defects, which is essential for high-quality manufacturing.

4. Environmental Sustainability: The manufacturing industry is becoming increasingly environmentally conscious, and fiber laser cutting is no exception. Innovations in this area include the use of eco-friendly cutting gases and the development of energy-efficient fiber lasers.

5. Artificial Intelligence and Machine Learning: Artificial intelligence and machine learning are being integrated into fiber laser cutting systems to improve efficiency and reduce downtime. This technology can predict and prevent equipment failures, optimize cutting parameters, and improve overall equipment performance.

In conclusion, the future of fiber laser cutting looks bright, with continued advancements in power, speed, automation, cutting quality, environmental sustainability, and artificial intelligence. These trends and innovations will undoubtedly shape the future of the manufacturing industry.