12, 2019

by Oree Laser

In the early period, Oreelaser has sorted out ten common problems of laser cutting carbon steel, this period, we bring common problems in the process of laser cutting stainless steel.

When laser cutting stainless steel, the stainless steel is melted and evaporated by the energy released when the laser beam is irradiated onto the surface of the steel sheet. And it is a fast and effective method to cut stainless steel by laser for the manufacture of stainless steel sheets.

If the laser cutting process parameters are strictly controlled during processing, the corrosion resistance of such materials can be maintained. And the most important process parameters affecting the quality of stainless steel cutting are cutting speed, laser power, and air pressure. Specific problems and debugging methods are as follows:

Produce tiny regular burrs in the shape of drops

Possible causes | Solutions |

The focus is too low | Raise the focus |

Feed rate is too high | Reduce the feed rate |

The two sides produce long irregular burrs, the surface of the board is discolored

| Possible causes | Solutions |

Feed rate is too high | Increase the feed rate |

The focus is too high | Reduce the focus |

Air pressure is too low | Increase air pressure |

The material is too hot | Cooling material |

Produce long, irregular burrs only on one side of the cut edge

| Possible causes | Solutions |

Nozzle misalignment | Centering nozzle |

The focus is too high | Reduce the focus |

Air pressure is too low | Increase air pressure |

The speed is too low | Increase speed |

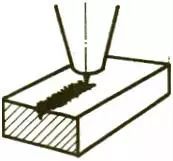

Material is discharged from above

| Possible causes | Solutions |

The power is too low | In these cases, press the pause button immediately to prevent slag from splashing onto the focusing mirror, increase power, reduce feed rate, and reduce air pressure |

Feed rate is too high | |

Air pressure is too high |

What should I do if the cutting edge is yellow?

| Possible causes | Solutions |

Nitrogen contains oxygen impurities | Use good quality, high purity nitrogen |

Professional Laser Cutting Machine Manufacturer - OreeLaser