02, 2020

by Oreelaser

I have been to many places, I have known many interesting souls, I have carried many meaningful stories in my heart, but I have never met, the scenery like you ---- Harpa Concert Hall, Iceland.

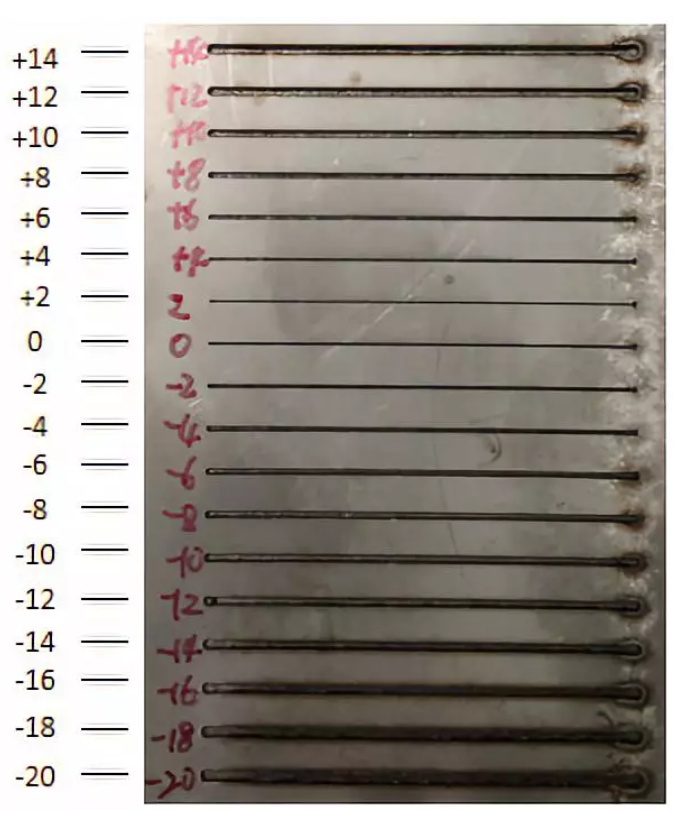

Definition of focus position

The distance from the focal point to the upper surface of the cutting workpiece. The position of the focal point above the workpiece is generally called the positive focal point, and the position of the focal point below the workpiece is generally called the negative focal point.

Focus position meaning

Changing the focus position means changing the spot size on the surface and inside of the board. The focus length becomes larger, the spot becomes thicker, and the slit becomes wider and wider, which in turn affects the heating area, slit size, and slag discharge capacity.

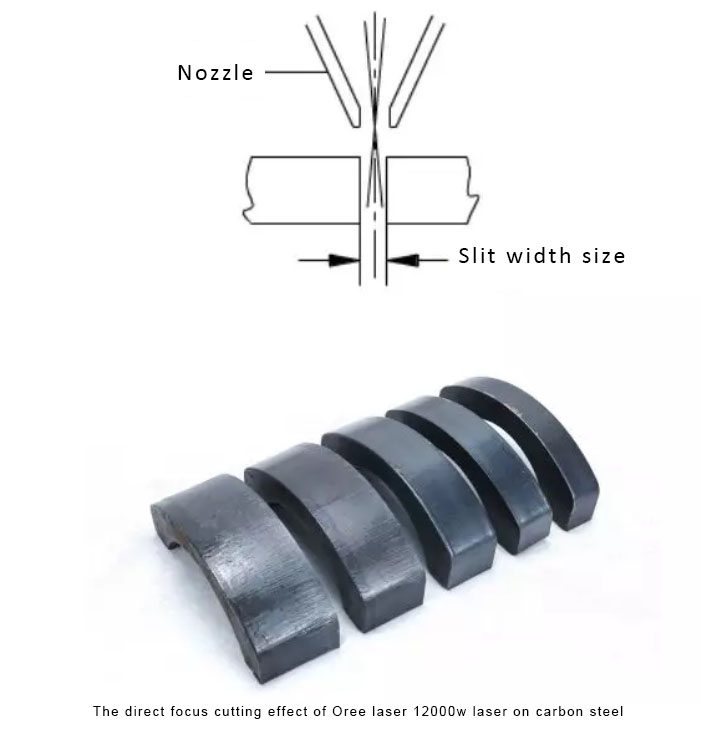

Positive focus cutting

That is, the cutting focus is on the workpiece, the focus is positioned above the cutting material.

For carbon steel oxygen cutting, it is suitable to adopt a positive focus. The bottom slit of the workpiece is wider than the upper surface slit, which is beneficial to slag discharge and oxygen to the bottom of the workpiece to participate in the full oxidation reaction. In a certain focus range, the larger the positive focus is, the larger the size of plate surface spot, the more sufficient preheating and heat supplement around the cutting seam, the smoother and brighter the carbon steel cutting surface.

For ten thousand watt laser pulse cutting stainless steel plate, the positive focus is adopted and the cutting is stable, which is beneficial to slag discharge and is not easy to reverse blue light.

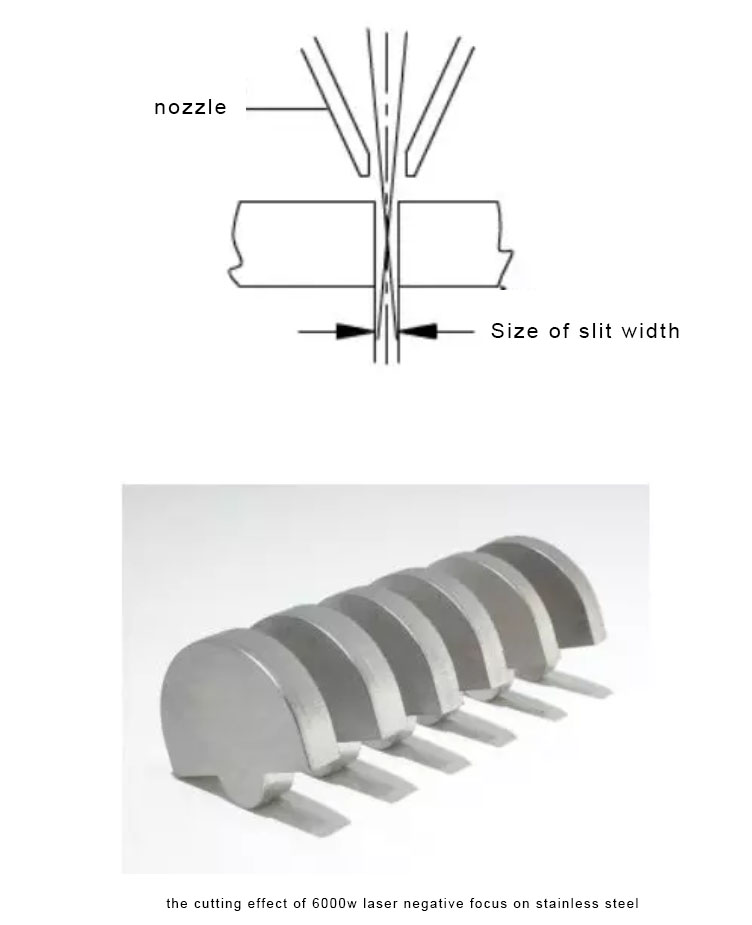

Negative focus cutting

That is, the cutting focus is in the workpiece. In the mode, as the focus is far away from the cutting surface, the cutting seam is wider than the cutting point on the workpiece surface, and the required cutting airflow is large and temperature is sufficient.

When cutting stainless steel, it is suitable to adopt negative focus cutting, uniform cutting surface and goog section.

For plate perforation before cutting, due to a certain height of perforation, negative focus is adopted for perforation position, which can ensure the minimum spot size and maximum energy density of the perforation position. Moreover, the deeper the perforation position is, the greater the negative focus is.

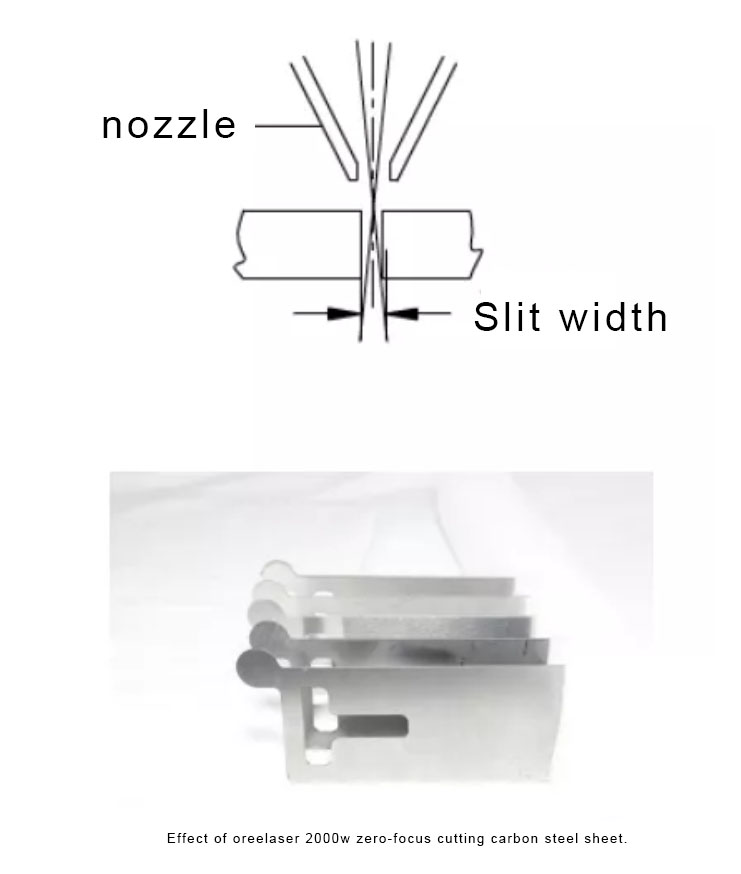

Zero focus cutting

That is, the cutting focus is on the surface of the workpiece, which is generally relatively smooth near the cutting surface of the focus, while the lower surface away from the cutting focus appears rough.

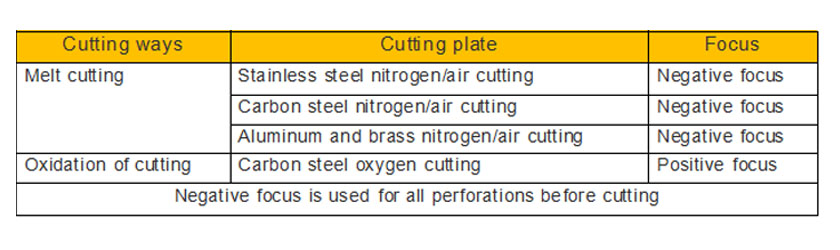

The positive and negative selection of the focus of the laser cutting is not determined by the cutting plate material(stainless steel, carbon steel), but by the cutting method(oxidation cutting, melting cutting).

Laser cutting machine processing different workpiece need to use different focus mode, because different types of cutting head focus position and adjustment mode are different, users can choose the appropriate focus cutting mode according to the different effects of the positive and negative focus cutting stainless steel and carbon steel, combined with their own processing needs, in order to give full play to the performance advantages of laser cutting machine!

Professional Laser Cutting Machine Manufacturer - OreeLaser