09, 2018

by Ada.liu

Due to the emergence of fiber laser cutting machines, the application of laser technology has been subverted. Laser cutting machines is not an original luxury but have been widely used in various industries. Now when you want to buy a fiber laser cutting machine, there will be Dozens of suppliers are flocking to each other, and there are a lot of machines with prices ranging from 200,000 to millions. Every manufactures will make their products better and make you dazzled, difficult to distinguish. So you don't know how to choose. Oree Laser, a professional manufacturer engaged in the R&D and manufacturing of the laser industry for many years, teaches you how to choose a suitable laser cutting machine.

Before buying a fiber laser cutting machine, many consumers may have all kinds of questions. Like what are the classifications of the cutting machine? What is the difference between them? How to choose a fiber laser cutting machine that suits your needs? Here, I will talk to you about the choice of fiber laser cutting machines.

Firstly, you must know why you want to choose a fiber laser cutting machine

Laser technology has developed rapidly in recent years and has become a mainstream cutting technology. In industrial production, laser cutting accounts for more than 70% of laser processing and is the most important application technology in the laser processing industry. With the increase of processing precision requirements and the rising price of raw materials worldwide, low-consumption, high-efficiency, and high-precision laser devices have become the focus of attention. According to different laser generators, the current market can be roughly divided into three types: CO2 laser cutting machine, YAG (solid) laser cutting machine, fiber laser cutting machine

The advantages of the fiber laser cutting machine compared with the co2 cutting machine

1) Excellent beam quality: Smaller spot size, finer cutting lines, higher work efficiency and better processing quality.

2)Extremely high cutting speed: twice the same power of the CO2 laser cutting machine.

3)High stability: Using the world's top imported fiber laser, stable performance, and critical component life of up to 100,000 hours.

4)Extremely high electro-optical conversion efficiency:The photoelectric conversion efficiency of fiber laser cutting machine is about 30%, which is 3 times higher than CO2 laser cutting machine,energy saving and environmental protection.

5)Very low cost of use: The power consumption of the whole machine is only 20-30% of the same CO2 laser cutting machine.

6)Very low maintenance costs: No laser working gas; fiber transmission, no need for reflective lenses; can save a lot of maintenance costs.

7)Easy operation and maintenance of the product: optical fiber transmission, no need to adjust the optical path.

8)Superior flexible light guiding effect: Compact size, compact structure and easy flexible processing requirements.

The advantages of the fiber laser cutting machine compared with the YAG solid cutting machine:

1)Cutting speed: Fiber laser cutting machine is 4-5 times faster than YAG, suitable for large-scale processing and production

2)Cost of use: Fiber laser cutting machine is less expensive to use than YAG solid laser cutting

3)Photoelectric conversion efficiency: The photoelectric conversion efficiency of fiber laser cutting machine is about 10 times that of YAG

Secondly, it is the paving of a better understanding of the fiber laser cutting machine itself to choose a suitable machine.

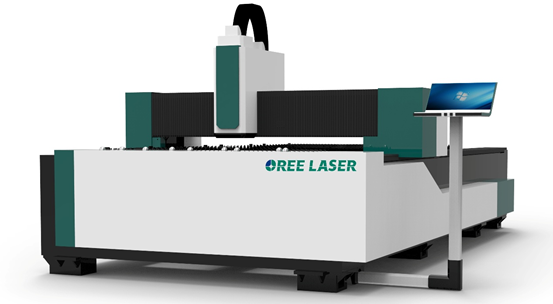

Definition and working principle

A fiber laser cutting machine is that uses a fiber laser generator as a light source. Fiber laser is a new type of fiber laser that is newly developed in the world. It outputs a high-energy-density laser beam and accumulates on the surface of the workpiece, so that the area of the workpiece that is illuminated by the ultra-fine focus spot is instantly melted and vaporized, and the spot is moved by the numerical control mechanical system. Automatic cutting is achieved by illuminating the position. Compared with solid gas lasers and solid-state lasers, it has obvious advantages and has gradually become an important candidate in high-precision laser processing, laser radar systems, space technology, laser medicine and other fields. Compared with ordinary carbon dioxide laser cutting machine, it saves space and gas consumption, has high photoelectric conversion rate, is a new product of energy saving and environmental protection, and is also one of the world's leading technology products.

Main features of fiber laser cutting machine

(1) The fiber-optic laser has high electro-optical conversion efficiency and conversion efficiency of more than 30%. The low-power fiber laser does not need to be equipped with a chiller, and adopts air-cooling, which can greatly save power consumption during operation, save operating cost, and achieve maximum production efficiency.

(2) The laser only requires electrical energy when operating, and does not require additional gas to generate lasers, with minimal operating and maintenance costs.

(3)The fiber laser adopts the modular and redundant design of the semiconductor. There is no optical lens in the resonant cavity. It does not require startup time. It has the advantages of no adjustment, maintenance-free, and high stability. It reduces the cost of accessories and maintenance time. It is comparative for the traditional laser.

(4) The output wavelength of the fiber laser is 1.064 micron, which is 1/10 of the CO2 wavelength. Moreover, it is beneficial to the absorption of metal materials with its good output beam quality and high power density. It has excellent cutting and welding ability, so that the processing cost is the lowest.

(5) The whole optical routing fiber transmission does not require a complicated light guiding system such as a mirror. Simple optical path, stable structure and the external optical path is maintenance-free.

(6) The cutting head contains protective lenses, making the consumption of expensive consumables such as focusing mirrors extremely small.

(7) Light is exported through fiber optics, making mechanical system design very simple and easy to integrate with robots or multi-dimensional workbenches.

(8) After the laser plus the shutter, it can be multi-machine, split by fiber, split into multiple channels and work at the same time, and it is easy to expand functions and simple to upgrade.

(9) The fiber laser is small in size, light in weight, movable in working position, and small in footprint.

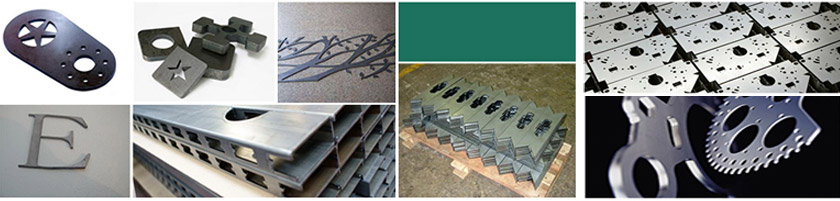

Industry application

Used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, grain machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising , metal processing, kitchen processing, and other manufacturing and processing industries.

processing material

stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, galvanized sheet, galvanized sheet, pickling board, copper, silver, gold, titanium and other metal sheet and pipe cutting.

Cutting advantage

1. High cutting precision: laser cutting machine positioning accuracy 0.05mm, repeat positioning accuracy 0.03 mm.

2. The laser cutting machine with a narrow slit: the laser beam is focused into a small spot, so that the focus reaches a high power density, and the material is quickly heated to a vaporization level to evaporate to form a hole. As the beam moves relatively linearly with the material, the holes are continuously formed into slits having a narrow width, and the slit width is generally 0.10-0.20 mm.

3.The cutting surface of the laser cutting machine is smooth: the cutting surface is free of burrs, and the surface roughness of the cutting surface is generally controlled within Ra6.5.

4. Laser cutting machine speed: cutting speed up to 10m/min, maximum positioning speed up to 30m/min, much faster than wire cutting.

5.The laser cutting machine has good cutting quality: no contact cutting, the cutting edge is little affected by heat, and there is basically no thermal deformation of the workpiece, completely avoiding the collapse formed when the material is punched and sheared, and the slit generally does not require secondary processing.

6.Does not damage the workpiece: the laser cutting head does not touch the surface of the material, ensuring that the workpiece is not scratched.

7.Not affected by the shape of the workpiece: laser processing is flexible, can process any graphics, can cut pipes and other profiles.

8. Laser cutting machines can cut a variety of materials: plastic, wood, PVC leather, textiles, plexiglass, etc.

9. Saving mold investment: laser processing does not require molds, no mold consumption, no need to repair molds, saving mold replacement time, thereby saving processing costs and reducing production costs, especially for processing large products.。

10.Material saving: Computer programming can cut products of different shapes to maximize material utilization.

11. Improve the speed of sample delivery: After the product drawings are formed, laser processing can be performed immediately, and the new product can be obtained in the shortest time.

12. Safety and environmental protection: less laser processing waste, low noise, clean, safe and pollution-free, greatly improving the working environment.

Finally, after all the preparations are completed, you can boldly choose a machine that suits your needs. There are six points for your reference.

I. The range of materials and business needs of the company

First of all, we must consider the scope of our business, the thickness of the material to be cut, which materials need to be cut, etc., and then determine the power of the equipment and the size of the workbench to be purchased. The current power of the laser cutting machine on the market is from 500W to 6000W. The size of the workbench can be customized according to the needs of customers.

II. Initial choice of the manufacturer

After determining the demand, we can go to the market to find out or go to the peers who bought the laser cutting machine to see the performance and basic parameters of the machine. Choose a few manufacturers with strong price and favorable price to carry out pre-communication and proofing. Later, we can conduct on-the-spot investigation and discuss in more detail about the parts of the machine, the price of the machine, the training of the machine, the payment method, and the after-sales service.

III. Laser power

In the choice of laser cutting machine performance, we should fully consider the environment. It is very important to the laser power. For example, we often cut metal sheets below 6mm, then we choose 500W-700W laser cutting machine to meet the production demand, if you cut more than 6mm of material, we need to consider the machine with a larger power, which is very helpful for the cost control of the enterprise.

IV. The core part of the laser cutting machine

Some important parts of the laser cutting machine, we also need to pay attention when purchasing. In particular, laser generators, laser cutting heads, servo motors, guide rails, water tanks, etc., must be clearly defined as domestic or imported. These components directly affect the cutting speed and accuracy of the laser cutting machine. Many domestic manufacturers use domestically produced fake accessories to deceive customers.

V. Equipment quality and stability of use are also important metrics

Now the product development cycle is short, the update is getting faster and faster, the product variety, prototype trial production, mass production is more and more. Therefore it is also an arduous task placed in the front of each operators to how to complete customer orders with quality and quantity, maintain corporate reputation, and enhance corporate competitiveness. As a consumer, we need to have to pay more attention to the stable processing equipment, try to choose a market with high market share, a sound after-sales service system, after-sales service outlets and long-term market testing. Cannot purchase Low-cost and low-quality products without after-sales service just for the price, because you cannot imagine what a huge impact on the company's production.

VI. After-sales service

Each manufacturer's after-sales service varies widely, and the warranty period is also uneven. In the after-sales service, we not only provide customers with effective daily maintenance programs, but also have a professional training system for machines and laser software to help customers get started as soon as possible. There is also a laser cutting machine no matter how good it is, users will encounter various problems in the process of use, in the case of problems that customers cannot solve, which is especially important for the manufacturer to provide timely solutions. In a word, this is an important factor to consider when purchasing a laser cutting machine.

Professional Laser Cutting Machine Manufacturer - OreeLaser