09, 2018

by Ada.liu

Pipe cutting includes tube blank breaking, pipe wall cutting, grooving, and machining various intersecting line shapes at the end of the pipe structure. Commonly used are cold working methods, hot working methods and grinding wheel cutting. For small batches, it is the first choice to adopt the cold working method, such as turning, milling, circular saw cutting or grinding wheel cutting, whose main problem is low production efficiency and serious environment pollution. As an advanced processing tool, laser cutting machine is gradually entering the tube cutting market.

So how to choose the right pipe cutting equipment?

Firstly, let's take a look at the three common cutting methods we mentioned above.

I.Cold working method

Pipe cutting cold processing methods mainly include: sawing machine cutting, wire cutting, water cutting, shearing board cutting, punching processing, drilling processing, etc., the molding quality is generally high, but the efficiency is low, usually cannot meet the needs of mass production.

II.Hot working method

Pipe cutting thermal processing methods mainly include: wind cutting, plasma cutting and laser cutting. These three methods are methods of melting the tube cutting portion by heating to cut. Wind cutting is typically used for small manual cuts. Plasma cutting speed is fast and efficient, but the cutting quality is not as good as laser. However, the cost of purchasing and using the whole machine is much lower than that of the laser.

III.Grinding wheel cutting

This is a process between the hot working method and the cold working method. The cutting process is performed by the high-speed rotation of the grinding wheel, and the cutting process generates heat, which cannot be cooled by water. The processed tube has large burrs and the plane is not flat so that need generally follow-up processing. It would be not applicable for the cutting nozzle with high requirement.

Then you will ask, so many pipe cutting methods, why choose laser cutting, follow me please.

There are three advantages that other two cutting methods cannot approach it.

I.Flexibility

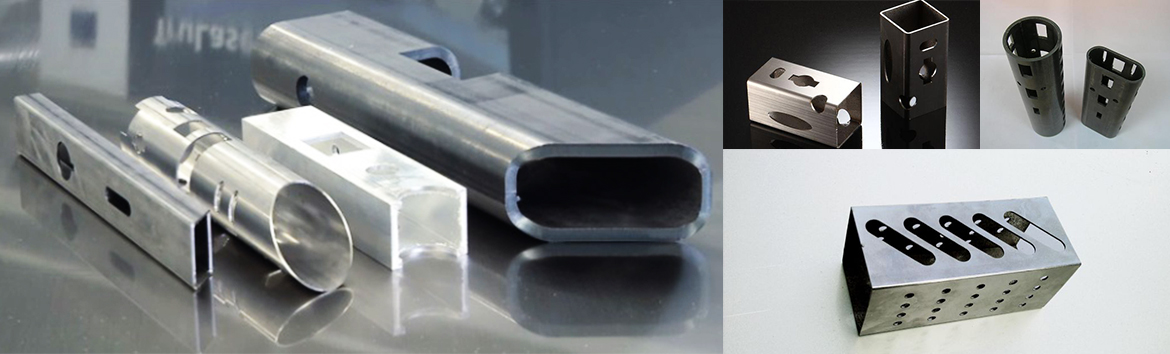

How can a pipe laser cutter be flexible? It almost can be realized what you want to cut. It can cut any shape that has been programmed on a stainless steel pipe, and the laser can be perfectly cut in any direction. The shape to be processed can be flexibly and quickly changed by computer programming. The high flexibility of the laser tube cutter provides a strong technical support for more and more individual processing, thus reducing the number of molds used.

II.Accuracy

Compared with traditional processing equipment such as flame cutting, plasma cutting, water cutting, laser cutting metal sheet is much more accurate, the cutting is smooth and clean, no burrs, and the material loss is very small. At the same time, as mentioned above, when different materials are processed, there will be some small telescopic deformation during the process, and the laser tube cutter can be flexibly adjusted according to these deformations, which is not achieved by many conventional processes.

III.High efficiency

High cutting efficiency enables mass production. All operations of laser cutting can be unified into the same unit as a continuous operation, greatly reducing logistics time. The standard pipe length is 6 meters. The traditional processing method requires very bulky clamping, but the laser processing can easily complete the positioning of several meters of pipe clamping, which makes batch processing possible.

What is the pipe laser cutting?

Laser cutting is achieved by applying high power density energy generated by laser focusing. Under computer control, the laser is discharged by pulse, thereby outputting a controlled repeated high-frequency pulsed laser to form a certain frequency and pulse width beam. The pulsed laser beam is transmitted and reflected through the optical path and focused by the focusing lens group. On the surface of the object, a subtle, high-energy density spot is formed, and the focal spot is located near the surface to be processed, and the material to be processed is melted or vaporized at an instant high temperature.

The high-energy laser pulse instantly sputters a small hole on the surface of the object. Under the control of the computer, the cutting head of the tube laser cutting machine and the material to be processed are continuously moved relative to each other according to the pre-drawn pattern, so that the object is processed to the desired shape.

At present, with the rapid growth of China's stainless steel pipe production and consumption, laser cutting equipment is rapidly spreading in China. Laser cutting technology at home and abroad is very mature, but customers still complain that even though the cutting machine equipment they buy is very advanced, the work efficiency is low during the production process. After careful discussion, a large part of the reason is because the company did not consider its own needs when purchasing the machine. What factors should be considered before purchasing the cutting machine? Today, I will talk about how to choose a suitable tube laser cutting equipment from two angles.

I.Customer demand

If some customers cut the pipe diameter from 25-150mm, the thickness is from 2.0-4.0mm, and then the cutting length is also long or short, he wants to be realized on a cutting machine. Before the emergence of automated cutting equipment, customers generally choose semi-automatic pipe cutting machine, because when the cutting length exceeds 1.5 meters, the traditional automatic pipe cutting machine needs to feed multiple times, so there is no efficiency advantage. However, during the use process, it was found that the semi-automatic pipe cutting machine could not achieve the desired precision and efficiency. It is a new choice for each pipe cutting enterprise to get a high-precision, labor-saving, and cost-effective cutting machine equipment.

II.Manufactures of pipe laser cutter

1.Brand

Brand is a comprehensive embodiment of the company. Different brands of products have different technologies and qualities. Once the quality problems occur, it not only affects the normal operation of the fiber laser cutting machine, but also reduces the service life of the fiber laser cutting machine. When choosing a fiber laser cutting machine, we must first pay attention to the screening of the brand. Because there are many types in the market, the qualifications of the enterprises are completely different. The brands we want to choose must first have the production qualification and the quality of the products must be guaranteed. What’s more, the manufacturer of pipe laser cutting machine must be professional. Because of the advanced technology of these companies, the products produced are better than small brands in terms of service life and performance. Secondly, the credit rating of the pipe fiber laser cutting machine of the big brand is relatively high. Once there is any problem during the use process, the user can enjoy good after-sales service.

2.Core components

If you decide to purchase a pipe laser cutting machine, there are also many details to be aware of during the purchase process. For fiber laser cutting machines, laser generators, transmission components, and optical components are the most critical factors related to the quality of fiber laser cutting machines.

There are two types of laser generators, imported and domestic. The import price is relatively high, but the stability is good, while the domestic laser generator price is low, the technology is relatively mature; the transmission parts have screw, guide rail and rack and pinion, screw, The accuracy of the guide rail is high and the bearing capacity of the rack and pinion is large. Therefore, we suggests that the small power fiber laser cutting machine should be better than for it’s good lead screw and guide rail. When purchasing a fiber laser cutting machine, it must be noted that the product configuration is the same as that on the equipment. If it is "hanging sheep head selling dog meat", which will greatly affect the overall life of the fiber laser cutting machine.

3.After-sales services

The pipe fiber laser cutting machine is a durable product, and its normal service life is 12-15 years. If the warranty period is not long enough, the maintenance problem after the warranty period will become a big problem that plagues the user. In order to provide users with strong after-sales guarantee, fiber laser cutting machine has a two-year warranty and lifetime maintenance. Therefore, users buy some big brands with better reputation and longer warranty.

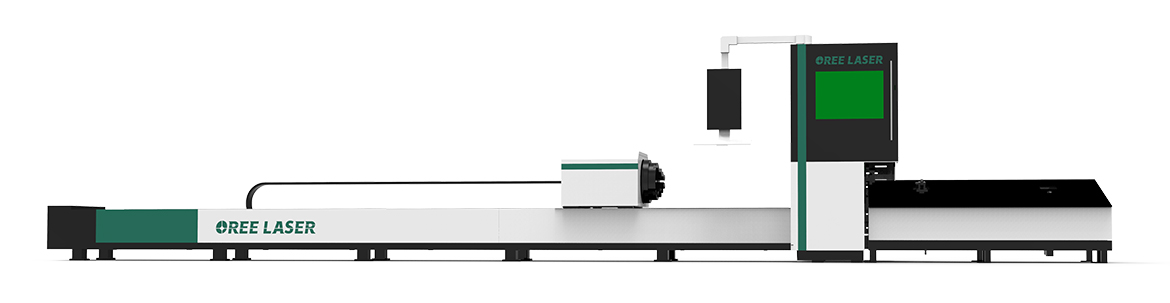

Professional Laser Cutting Machine Manufacturer - OreeLaser