07, 2019

by Oree Laser

In this Oree micro class we will learn 4 practical terms about laser cutting.Let's learn the following knowledge together.

1. Free stroke

“ Free stroke” can also be called 'free' run.

As shown below, according to the program, when the laser cutting machine completes the cutting of hole 1 to cut hole 2, the laser head moves from point A to point B at the same time without emitting light, this process from A to B is called "free stroke". And because the laser head in the process of moving does not generate laser, so also called "free run".

2. Leapfrog

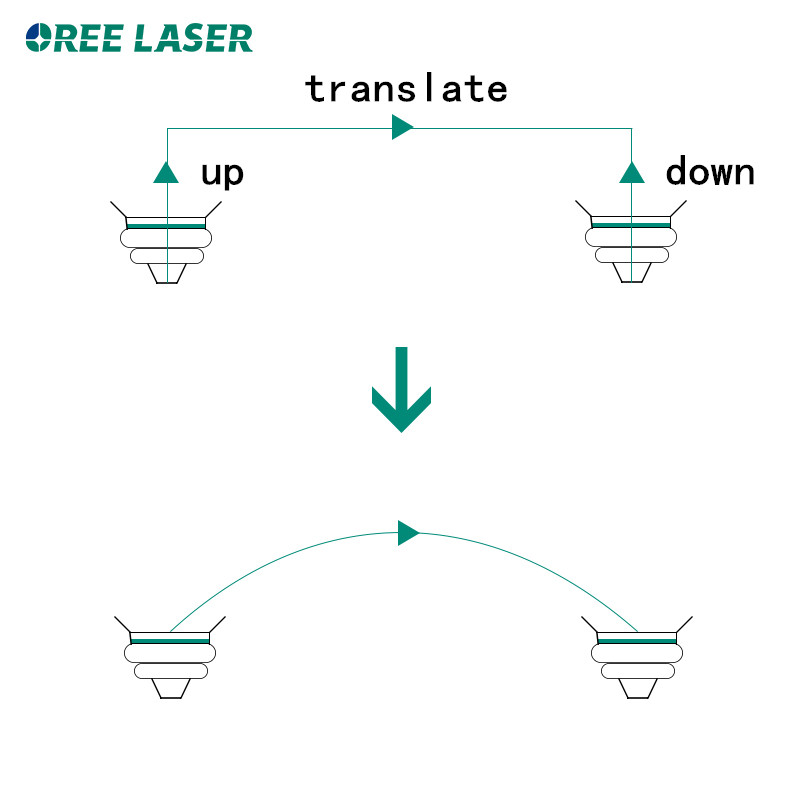

"Leapfrog" as the name implies is like frog jump, leapfrog is the laser cutting machine's free stroke way.The focus of leapfrog is to shorten the leapfrog time and improve the efficiency of laser cutting. Because the early laser cutting machine's free stroke way requires the laser head to do three actions: up-translate-down (as shown), which takes a long time. Later improved "leapfrog" free stroke way is to complete the three movements at the same time, saving time.

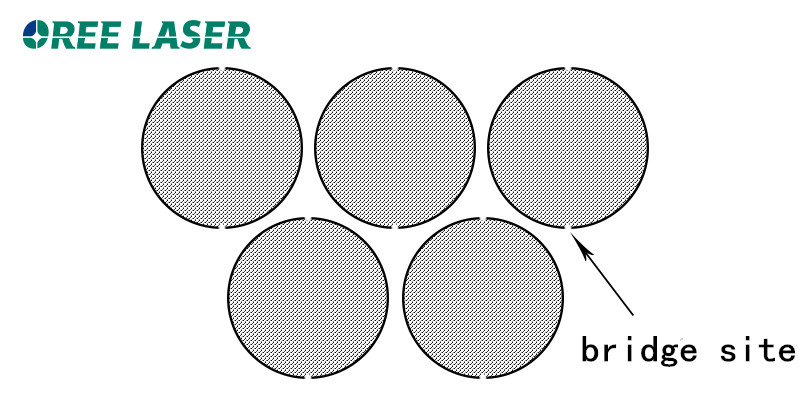

3.Bridge site

"Bridge site" can also be called "micro-connection", which refers to the tiny break point on the cutting contour line after cutting. These tiny bridge site can connect the sub material with the master batch, preventing the raw material that has been cut from being held up by the support bar, causing collision with the laser head and damaging the laser head.

4.Automatic tracing-edge

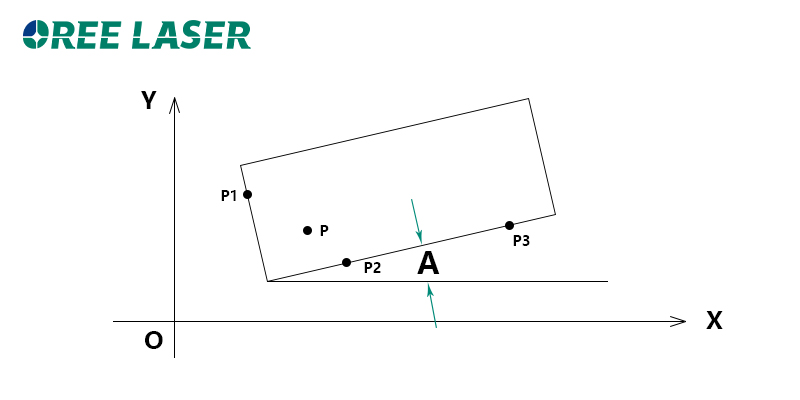

"Automatic tracing-edge" means that when the sheet material is placed askew on the table, the control system automatically senses the tilt angle and origin of the sheet material, and adjusts the cutting process accordingly, so as to be suitable for the angle and the position of the sheet material, and the tracing-edge cutting is carried out , thus avoiding waste.

As shown, after the automatic tracing-edge function is turned on, the laser cutting head will start from point P and automatically measure three points of the two vertical edges of sheet material: P1, P2, P3. Based on this, the tilt angle A of the sheet material and the origin of the sheet material are calculated automatically for cutting.

All right, that's all for today's sharing.See you next time.

Professional Laser Cutting Machine Manufacturer - OreeLaser