09, 2018

by Site Editor

I. Good grounding laser power supply, machine bed must have good grounding protection, ground wire application is less than 4Ω dedicated ground

Necessity lies in

1. Ensure the laser power supply works properly

2. Extend the life of the laser tube

3. Prevent the machine to beat from external interference

4. Prevent to cause circuit damage with high-voltage discharge

II. Cooling water must be kept open whether it is tap water or circulating water pump, the water flow must be maintained. Cooling water is to take away the heat generated by the laser tube. The higher the water temperature, the lower the light output power (15-20°C water temperature is preferred). When the water is cut off, the tube end will burst due to the heat accumulated in the laser cavity, and even the laser will be damaged. Therefore, it is very necessary to check whether the cooling water is unobstructed or not at any time.

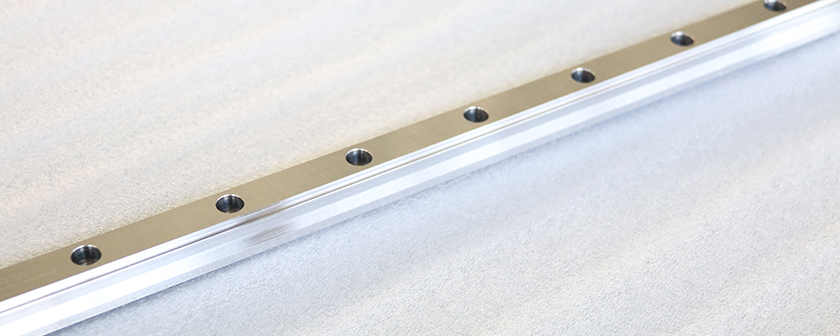

III. There are necessary conditions for the normal operation of the laser engraving machine, including cleaning and maintenance, good ventilation, and cleaning the machine at any time. If our joints are not flexible, we cannot move? In the same way, the machine tool guide is a high-precision core component. Every job must be cleaned and kept clean and lubricated. Each bearing must also be filled with oil regularly so that the drive can be flexibly and accurately processed, and the service life of the machine can be extended.

IV. Ambient temperature and humidity ambient temperature should be in the range of 5-35°C. Special attention is: the following must be done if in an environment below freezing:

1. Prevent the circulating water freezing in the laser tube and radiate the water completely after the machine shutdown

2. When the camera is turned on, the laser current must be warmed up for more than 5 minutes to work. In the rainy days or humid environment, the laser power supply requires a longer warm-up time, and it is necessary to add high pressure after the dehumidification, so as to prevent breakdown of the high-voltage circuit.

V. Dial the key of “high laser pressure” in correctly, when the key works, the laser power supply is in a standby state. When it encounters “manual light output” or a computer malfunctions, it will emit laser light, which will wound human and injured inadvertently. Therefore, it is required to turn off “laser high pressure” at any time for each completed work, such as discontinuous processing, (the laser current may not be turned off), and the operator is prohibited from leaving without authorization when the machine is in operation to avoid accidents. It is recommended that the continuous working time be less than 5 hours and the operator should rest 30 minutes in the middle.

VI. Stay away from strong battery shocks, it may sometimes cause the machine to malfunction. Although it is rare, it should be avoided as much as possible. Such as large electric welders, giant electric mixers, and large power transmission and transformation equipment, should be far away. Strong vibration equipment is more self-evident, such as forging presses, vibrations caused by the walking of a close range motor vehicle, etc., the apparent jitter of the ground is very unfavorable for accurate engraving.

VII. Lightning strike as long as the building lightning protection measures can be reliable. As well as good grounding can also help prevent lightning. Special advice: In unstable areas (such as voltage fluctuations exceeding 5%), users are requested to install a regulated power supply with a capacity of at least 3000 W to prevent sudden voltage surges from burning down the circuit or the computer.

VIII. Maintain the stability of the control PC. The control PC is mainly used to control the engraving equipment. In addition to installing the necessary graphic design software, please do not use special planes. Because computer add network card and anti-virus firewall, it will seriously affect the speed of the control machine. Please do not install anti-virus firewall on the control machine. If you need a network card for data communication, please disable the network card before starting the laser engraving machine.

IX. Maintenance of the guild rail : there will be generated a large amount of dust due to the processed material during the movement of the guide rail. Maintenance method: Firstly wipe the original lubricating oil and dust on the guide rail with cotton cloth, wipe it clean, and then apply a layer of lubricating oil on the surface and side of the guide rail. Maintenance cycle: about a week。

X. Maintenance of the fan: After the fan has worked for a period of time, a large amount of dust will accumulate in the fan and the exhaust pipe. Dust will affect the efficiency of exhausting the fan and cause a large amount of dust to be discharged. Maintenance method: Loosen the connecting hose clamp of the exhaust pipe and fan, remove the exhaust pipe, and clean the dust in the exhaust pipe and fan. Maintenance cycle: about one month.

XI. Screw tightening: After a certain period of time in the motion system, the screws in the kinematic joint will loosen. After loosening the screws, it will affect the smoothness of the mechanical movement. Maintenance method: Use the supplied tools to tighten the screws one by one. Maintenance cycle: about a month.

XII.Maintenance of the lens: After the machine is working for a period of time, the lens will have a layer of gray on the surface due to the working environment, which will reduce the reflectivity of the reflective lens and the transmittance of the lens, and ultimately affect the working power of the laser. Maintenance method: Wipe the surface of the lens clockwise with a cotton wool to remove dust.

If you pay attention to the above situations, I believe that your laser machine life will be more long-lasting, and the efficiency of use will be greatly increased.

Professional Laser Cutting Machine Manufacturer - OreeLaser