10, 2019

by Oree Laser

With the popularity of laser cutting technology in the manufacture field, the quality of laser cutting is closely related to the productivity and efficiency of majority of equipment application customers. In the laser cutting process, the factors affecting the cutting quality performance are laser beam quality, laser power, cutting speed, workpiece thickness, material type, etc. In addition, cutting head nozzle design, airflow control, etc. are also important factors.

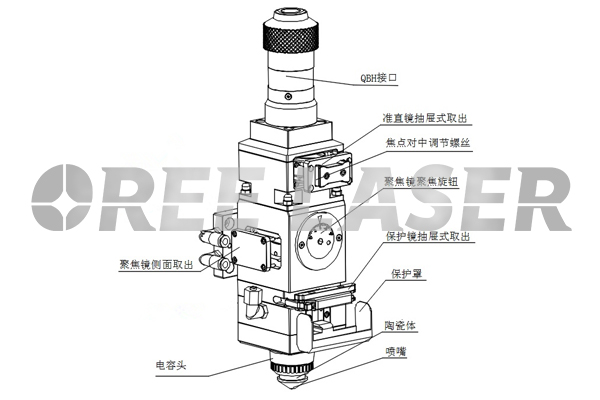

The cutting head nozzle is installed at the front end of the Oree cutting head to help control the auxiliary gas while protecting the focusing lens. The cutting material is kept at a stable distance from the nozzle during the cutting process to prevent splash bounce when cutting. The diameter of the nozzle determines the airflow shape, the gas diffusion area and gas velocity entering the incision, thus affecting the removal of the melt and the cutting stability. The greater the flow rate into the slit, the faster the speed and the workpiece is in the right position in the airflow, the ability to spray to remove the melt.

In the actual use process, when the nozzle and laser output beam are not coaxial, in order to ensure effective cutting , avoiding the problem of excessive slit width, nozzle damage, cut surface melt, etc.. The center of the nozzle hole should be coaxially with the laser beam.

Specific method:

Apply white adhesive to the end face of the nozzle outlet, adjust the laser output power for punching, observe whether there is a center hole on the white adhesive and the location of the center hole, simultaneously adjust the adjustment screw on the mirror cavity handle until the laser hole on the white adhesive is coincident with the nozzle center, thus confirming the laser output center is consistent with the nozzle center.

Professional Laser Cutting Machine Manufacturer - OreeLaser