03, 2019

by oreelaser

With the rapid development and wide application of laser technology, we can see a wide variety of laser products in our living environments. Some laser products can be used safely, but some improper use can cause serious damage to our eyes and skin, and even cause serious accompanying hazards such as fire, electric shock and burns. So how do you know if a laser product is safe?

In order to allow the user to easily identify the hazard level of the laser product, we can classify the laser product according to the damage mechanism of the laser product to the human tissue and the degree of damage caused.

The wavelength and power of the laser product determine the damage the laser has on different tissues of the human body. The wavelength determines the absorption characteristics of the laser and the mechanism of the damage of different human tissues. The power and energy determine the degree of laser damage. The International Electro technical Commission standard divides laser products into several major safety levels based on the wavelength of the laser product, the maximum output laser power or energy. They are like the business card of a laser product, representing the degree of harm of the laser product, and the user needs to pay attention to it.

Therefore, whether it is an ordinary consumer or a professional operator, we must correctly understand the level of the laser, understand the degree of hazard and precautions that it represents, and can avoid many laser injury accidents.

Laser safety rating classification details:

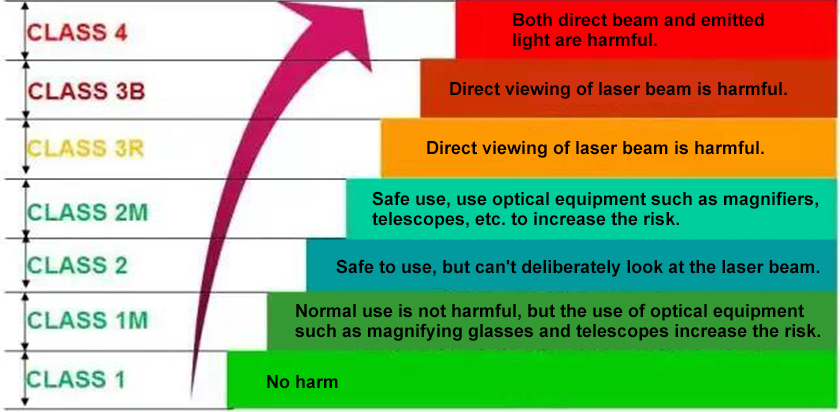

The International Electro technical Commission standard (IEC 60825-1) classifies laser products into the following seven grades based on the wavelength of the laser product and the maximum output laser power: 1, 1M, 2, 2M, 3R, 3B, 4. The 1M and 2M grades represent the same level of safety as the 1st and 2nd grades. However, when using optical equipment such as telescopes, the degree of damage may be amplified to exceed the damage of Levels 1 and 2. Level 3 is also divided into two sub-levels, 3R and 3B.

Next, we use Figure 1 and Table 1 to understand the specific classification and the degree of harm represented by different categories:

Table 1: Laser class classification represents hazard details

Knowing the significance of the laser hazard level, let's see how we can know the level when we see a laser.

In fact, laser products that have been rigorously tested and certified have obvious laser grade markings where they are visible, as shown in Table 2 below.

Table 2: Laser level identification and warning

According to the classification criteria of laser grades, different grades represent different hazard levels and usage restrictions, so not all products can be sold in any market at any laser level. Next, we will discuss several common problems with laser levels, and I hope to draw your attention:

1. Do children's toy laser products have to meet Class 1 requirements?

When laser technology is applied to toys, whether it is visible or invisible lasers, special attention should be paid to children who are curious and do not understand the meaning of the warning signs. They may continue to look at the laser in a very dangerous way and cause serious eyes. hurt. At present, especially in China, many children can easily obtain products such as laser pens or toy laser projectors. The laser power of some products is much higher than the limit of Class 1, which is a very big safety hazard.Therefore, countries are required to require toy laser products to meet the Class 1 rating.

2. Is the Class 1 laser absolutely safe?

Some Class 1 lasers do not pose a hazard to humans because of their inherently low transmit power, but not all lasers do. There are many lasers classified as Class 1 that may use Class 3B or 4 laser sources internally. If we use them improperly, when opening the protective casing of the machine or deliberately changing the optical path, it may cause a higher level of laser beam leakage, resulting in Personal hazard.

3.Why do the indicator lasers must be set within Class 2 first?

Laser pens, laser measuring equipment, tools with laser indicating equipment, etc., can be accessed or used by ordinary consumers, and their grades are generally not higher than Class 3R. Some markets, such as Europe, Australia, etc., require indicator lasers, such as laser pens, to meet the requirements of Clsss 2 or lower to be sold.

4. What if we can't determine the level of the laser?

During the development and debugging process, we sometimes cannot determine the laser level of a certain part of the product. At this time, we cannot simply assume that the level is the same or a low level as the laser source because of trouble. On the contrary, we generally want Assume that it is Class 3B or even Class 4, and take adequate safety measures such as wearing laser safety glasses and protective gloves to avoid accidents.

Professional Laser Cutting Machine Manufacturer - OreeLaser