12, 2018

by OREELASER

Laser cutting uses laser energy to cut the material to obtain the desired workpiece. For example, stainless steel, carbon steel, etc., the irradiated material is rapidly melted, vaporized, ablated or reaches a burning point, and the molten material is blown off by a high-speed airflow coaxial with the beam, thereby cutting the workpiece.

If the laser cutting process parameters are strictly controlled during the cutting process, the cutting quality can be maintained. The most important process parameters affecting the quality of material cutting are cutting speed, laser power, focus position, auxiliary gas pressure, nozzle height, and nozzle diameter. The specific problems and debugging methods for cutting stainless steel and carbon steel are as follows.

Fiber laser cutting for carbon steel

Fiber laser-cut stainless steel is a tiny regular burr that produces droplets.

The reasons and solutions for the condition that there are some tiny regular burr when the fiber laser cutting.

1.If the focus is too low, we should raise the focus.

2.If the feed rate is too high, we should slow down the speed.

3.If the power is not big enough, we should increase the power.

The reasons and solutions for the condition that there is long irregular burrs only on one side of the cutting edge.

1.If the nozzle misalignment, we should make the nozzle centering

2.If the focus is too high, we should reduce the focus.

3.If the air pressure is too low, we should increase air pressure.

4.If the speed is too low, we should accelerate the cutting speed.

5.If the nozzle diameter is too small or the nozzle hole is not round, we should check the nozzle hole condition with a nozzle with a larger diameter.

The reasons and solutions for the condition that there is long irregular burrs on both sides, discoloration of the surface of the cut sheet.

1.If the feed rate is too slow, we should raise the speed.

2.If the focus is too high, we should reduce the focus.

3.If the air pressure is too low, we should increase air pressure.

4.If the nozzle is too small, we should change a bigger one.

The reasons and solutions for the condition that cutting material from above the machine.

1.If the focus is too slow, we should raise the focus.

2.If the power is too small, we should raise the power.

3.If the feed rate is too big, we should reduce the speed.

Note: if the above situation occurs, please press Pause immediately to prevent slag from splashing onto the focusing mirror.

The reasons and solutions for the condition that cutting edge color is yellow.

1.If the Nitrogen concentration is not pure, we should check the Nitrogen purity

2.If the Oxygen or air in the trachea, we should check if the oxygen solenoid valve or air solenoid valve is not tight.

Note: The principle of laser cutting of aluminum alloy and brass is the same as that of stainless steel, and the problems caused by cutting are similar. The difference is that due to the high reciprocity of aluminum alloy and brass, the other parameters are similar to those of stainless steel, as long as appropriate reduce cutting speed and introduce line speed. When cutting brass above 3mm, oxygen is recommended for the auxiliary gas.

Fiber laser cutting for Carbon steel

The reasons and solutions for the condition that the bottom of the pull line has a large offset and the bottom of the cut is wide.

1.If the feed rate is too high, we should slow down the speed.

2.If the power is too small, we should raise the power.

3.If the air pressure is too low, we should increase air pressure.

4.If the focus is too high, we should reduce the focus.

The reasons and solutions for the condition that the burrs on the bottom surface are similar to slag, drip and easy to remove.

1.If the feed rate is too high, we should slow down the speed.

2.If the air pressure is too low, we should increase air pressure.

3.If the focus is too high, we should reduce the focus.

The reasons and solutions for the condition that metal burrs on the underside are difficult to remove.

1.If the feed rate is too high, we should slow down the speed.

2.If the air pressure is too low, we should increase air pressure.

3.If the focus is too high, we should reduce the focus.

The reasons and solutions for the condition that only burrs on one side of the sheet cut.

1.If the nozzle alignment is incorrect, we should make the nozzle centered.

2.If introducing line speed too fast or introducing in a wrong way, we should reduce the incoming line speed or change the lead-in mode.

The reasons and solutions for the condition that cutting surface is not precise.

1.If the air pressure is too high, we should reduce air pressure.

2.If the focus is too high, we should reduce the focus.

3.If the diameter of the nozzle is too big, we should install a suitable one.

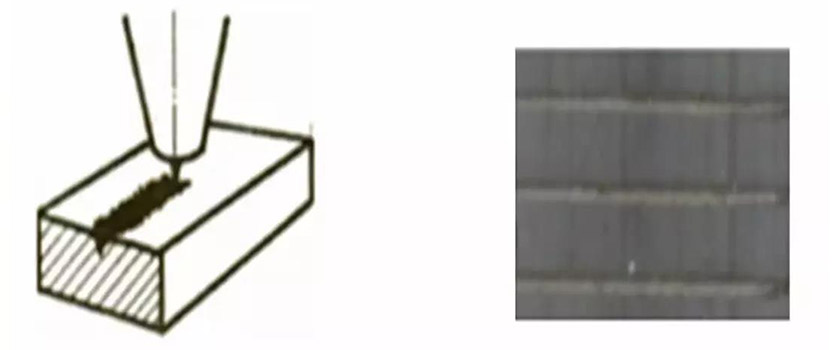

The reasons and solutions for the condition that the cut surface is very rough.

1.If the focus is too high, we should reduce the focus.

2.If the air pressure is too high, we should reduce air pressure.

3.If the feed rate is too slow, we should raise the speed.

Note: The cutting principle of structural steel is the same as that of carbon steel. Therefore, their laser cutting process can be debugged with reference to carbon steel, and the problem defects can also be solved by referring to the above carbon steel method.

Professional Laser Cutting Machine Manufacturer - OreeLaser