12, 2019

by Oree Laser

Mobile phones have been an indispensable personal item in People’s Daily life. A smartphone can achieve all the functions of instant messaging, taking photos, using apps, playing games, and even paying for purchases. “Laser” as an advanced processing technology has played a pivotal role in the manufacturing process of mobile phones! Today, Oree will introduce the application of laser welding technology in mobile phones.

▲Oree hand-held laser welding machine

The laser welding machine uses high-energy laser pulses to locally heat the material in a small area. The energy of laser radiation is diffused into the material through thermal conduction, and the material is melted to form a specific molten pool to achieve the purpose of welding. Laser welding has a small heat-affected zone, small deformation, fast welding speed, flat and beautiful welding seams, and is suitable for welding various parts of mobile phones.

● Application on frame and shrapnel in mobile phones

▲ laser-welded mobile phone shrapnel

Mobile phone shrapnels, like a hub connecting 4G and 5G, connect the aluminium alloy middle frame with other material structural parts of the mobile phone middle plate. The laser welding method is used to weld the metal elastic sheet to the conductive position, which plays the role of oxidation resistance and corrosion resistance. Materials such as gold-plated aluminium, copper-plated steel, and gold-plated steel can also be welded to mobile phones.

● Application on mobile phone USB data cable power adapter

▲ laser welding of USB data cable for mobile phone

USB data cables and power adapters play an important role in our life. At present, many domestic manufacturers of electronic data cables use laser welding technology.

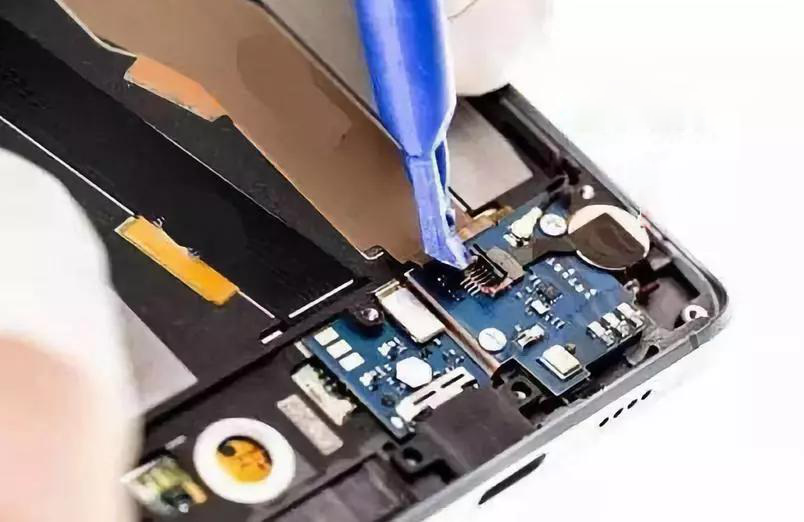

● The application between metal parts inside the mobile phone

▲laser welding of internal parts of mobile phones

There are so many metal parts inside mobile phones, so they need to be connected. Common mobile phone parts welding include resistance capacitor laser welding, mobile phone stainless steel nut laser welding, mobile phone camera module laser welding, and mobile phone camera RF antenna laser welding. The laser welding machine does not require tool contact during the welding process of the camera of the mobile phone, which avoids the surface damage of the device caused by the contact between the tool and the surface of the device, and has higher processing precision, is a new type if microelectronic packaging and interconnection technology, which can be perfectly applied to the processing of metal parts in mobile phones.

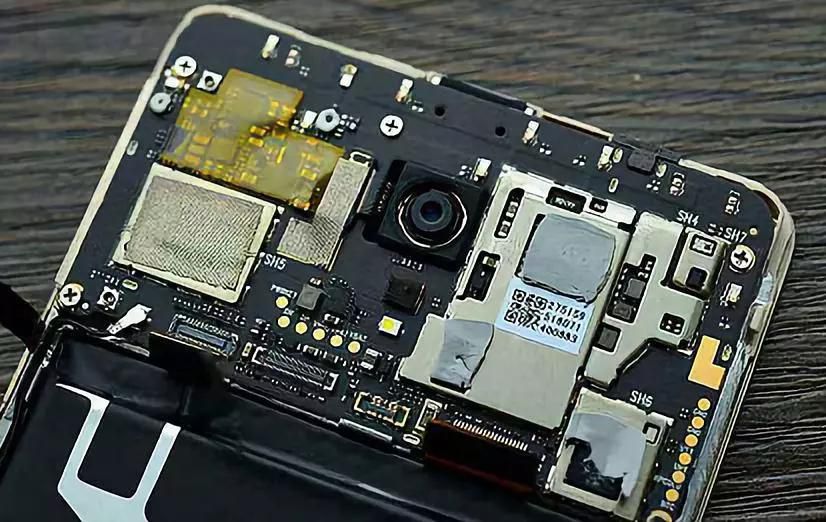

● Application in mobile phone chip and PCB board

▲mobile phone main-board welding built-in memory chip

The chip usually refers to a chip applied to the communication function of a mobile phone. The PCB is support for electronic components and a provider of electrical connections for electronic components. With the development of thin and light mobile phones, traditional soldering is no longer suitable for welding internal parts in mobile phones. Laser welding has continuously penetrated every industry since its development. With its welding efficiency and quality, laser welding has high quality and long service life and can realize automated production. And many manufacturers are using it.

Professional Laser Cutting Machine Manufacturer - OreeLaser