10, 2018

by Oreelaser

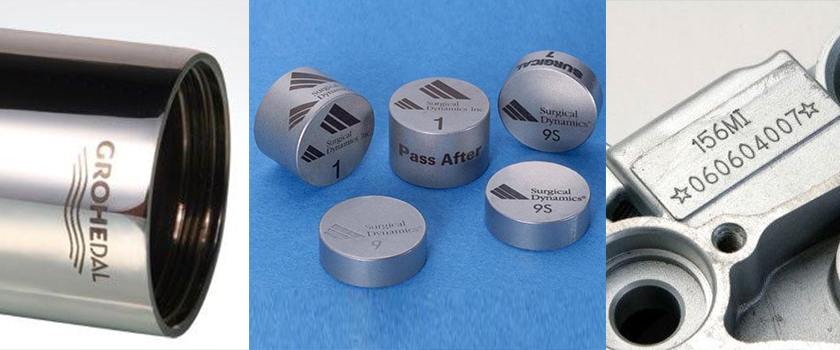

With the development of laser technology, laser marking, laser welding and laser cutting are more and more widely used in the industrial field, such as the electronics industry, automobile manufacturing, hardware, shipbuilding, civil and military fields. As one of the indispensable processing methods in many fields, laser marking technology has greatly promoted the development of these industries and brought new vitality to these industries.

At the same time as the scope of laser application is gradually expanding, the market demand for laser technology is also increasing. It is gradually reducing the market share occupied by traditional methods. Laser marking is one of the directions for laser applications, and the market is becoming more and more active for the following three reasons.

Firstly, the wide marking range. Laser marking machine marking work is suitable for a wide range of materials and can be used on almost all materials.

1.Electronic communication components industry: resistors, capacitors, chips, keyboards, light-transmitting buttons, electronic housings, wall switch panels, optical cables, cables, printed circuit boards, mobile phone cases, MP3, MP4 chassis, etc.

2. Auto parts: pistons, piston rings, gears, shafts, bushes, clutches, lights, etc.

3. Mechanical parts: bearings, gears, standard parts, motors and so on.

4. Instrumentation: panel, signage, precision equipment, metal case, watch bottom, glasses frame, etc.

5. Hardware tools: tools, tools, measuring tools, cutting tools, scissors, screwdrivers, vise, wrenches, stainless steel tableware, fitness equipment, stainless steel products, zipper heads, buttons, luggage buckles, belt buckles, carabiner and so on.

6. Daily necessities: crafts, zippers, key chains and so on.

7. Signage tag industry: equipment signs, signs, badges, pen box trophies and other medals, mobile phone chains.

8. Gift industry: metal gifts, advertising gifts, pens, pens, pen holders, lighters, smoking, stainless steel cups, mugs, Switzerland, nail clippers, keychains, gift watches, tin tea cans, tin cover, tin plate, U disk, notebooks, business card boxes, tableware, etc.

9. Wood craft industry: wooden crafts, calligraphy and painting reproduction and loading table, furniture craft decoration

.

10. Packaging bottle cap industry: tobacco, food, medicine, cosmetics and other internal and external packaging, metal bottle caps, cans, etc.

Secondly, the characteristics of laser marking:

1. Can process most metal and non-metal materials.

2. The laser is processed by non-mechanical “tool”. It does not produce mechanical extrusion or mechanical stress on the material, no “tool” wear, no toxicity, and rarely causes environmental pollution.

3. The laser beam is very thin, so that the consumption of the material to be processed is small.

4. When processing, X-rays are not generated as in the processing methods such as electron beam bombardment, and are not interfered by electric fields and magnetic fields.

5, the operation is simple, the use of microcomputer numerical control technology can achieve automated processing, can be used in the production line for high-speed and high-efficiency processing of parts, can be part of the flexible processing system.

6, using precision workbench for fine micromachining.

7. Use microscopic or camera system to observe or monitor the surface condition being processed.

8, through the light-transmissivity materials (such as quartz, glass), processing its internal components.

9. The prism and mirror system (for ND: YAG lasers can also use fiber optic light guide systems) can be used to concentrate the beam onto the inner or inclined surface of the workpiece for processing.

10, can mark barcodes, numbers, characters, patterns and other signs.

11. The line width of these marks can be as small as 12mm and the line depth can be less than 10mm, so the surface of parts with "mm" size can be marked.

Thirdly, the advantage of laser marking:

1. It has the advantages of high speed, high precision, good quality and small deformation, which greatly improves the appearance image and brand effect of the product;

2, a wide range of applications, almost any material can be engraved, marked, coded;

3, no need to open the mold, the computer for editing, deformation is convenient, not subject to production restrictions, greatly shortening the new product development cycle and reducing development costs;

4, easy to use, any employee can learn the normal operation process of laser equipment in a short time;

5, to protect the environment, there is no product that is not conducive to the environment, and further create profit value on the basis of environmental friendliness;

6, can be a variety of materials, a variety of shape surface marking, will not produce unstable conditions and other conditions.

With the increasing market demand, more and more manufacturers are now investing in the laser equipment industry. There are more and more laser devices of different brands and models, which directly lead to the homogenization of products. Increasingly, the current market competition for laser equipment is becoming more and more active. If you want to stand out from the competition, you must constantly upgrade your technology, have your own core competitiveness, and develop new machines. In the customized design, as well as product services continue to strengthen, in order to attract customers and improve their competitiveness in the current market. Oree laser always take” quality tree brand, integrity win the world's ’business philosophy, wining the industry's unanimous praise.

Professional Laser Cutting Machine Manufacturer - OreeLaser