11, 2019

by Oree Laser

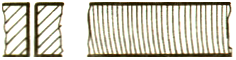

Laser-cut carbon steel plates are hot-cut. Under normal cutting conditions, the carbon steel cutting effect should be burr-free and the traction lines are consistent, as shown in the following figure.

However, due to some improper operation debugging, problems may occur and adjustments should be made according to the reasons.

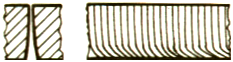

Bottom traction line has a large offset, and bottom incision is wider

| Possible Causes | Solutions |

Feedrate is too high | Reduce the feed rate |

Laser power is too low | Increase laser power |

Air pressure is too low | Increase air pressure |

The focus is too high | Reduce the focus |

The burr on the bottom surface is similar to slag, which is dripping and easy to remove

| Possible Causes | Solutions |

Feed rate is too high | Reduce the feed rate |

Air pressure is too low | Increase air pressure |

The focus is too high | Reduce the focus |

The metal burrs that are connected together can be removed as a single piece

| Possible Causes | Solutions |

The focus is too high | Reduce the focus |

Metal burrs on the bottom surface are difficult to remove

| Possible Causes | Solutions |

Feed rate is too high | Reduce the feed rate |

Air pressure is too low | Increase air pressure |

Gas is not pure | Use a purer gas |

The focus is too high | Reduce the focus |

There are only burrs on one side of the plate cut

| Possible Causes | Solutions |

Incorrect nozzle alignment | Centering nozzle |

The nozzle mouth is defective | Change nozzle |

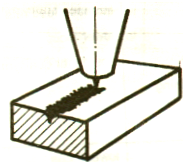

Material is discharged from above

| Possible Causes | Solutions |

The power is too low | Press the pause button immediately to prevent slag from splashing onto the focusing mirror. The increase the power and reduce the feed rate. |

Feed rate is too high |

The workpiece is not cut through

| Possible Causes | Solutions |

Processing gas error (N2) | Press the pause button immediately to prevent slag from splashing onto the focusing mirror. |

Feed rate is too high | Using oxygen as a process gas |

The power is too low | Reduce the feed rate and increase the power |

Cutting surface is not precise

| Possible Causes | Solutions |

Air pressure is too high | Reduce air pressure |

The nozzle is damaged | Replace nozzle |

Nozzle diameter is too large | Install a suitable nozzl |

Bad material | Use a material with a smooth surface |

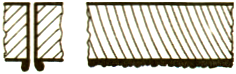

No burrs, the traction line is inclined, and the slit becomes narrower at the bottom

| Possible Causes | Solutions |

Feed rate is too high | Reduce the feed rate |

The cutting surface is very rough

| Possible Causes | Solutions |

The focus is too high | Reduce focus |

Air pressure is too high | Reduce air pressure |

Feed rate is too low | Increase feed rat |

The material is too hot | Cooling material |

Professional Laser Cutting Machine Manufacturer - OreeLaser