11, 2020

by Oree Laser

Fiber laser cutting machine has the advantages of cutting metal materials at high speed and high precision, and has become the first choice for metal processing equipment in many industries. Different accessories have different effects on the cutting effect of the laser cutting machine. So how to choose the core components of the laser cutter?

The core accessories of fiber laser cutting machine are: fiber laser, servo motor, control system, cutting head, laser lens, etc.

Fiber-optic laser

It is equivalent to the heart of the laser cutting machine and the core accessory of the laser cutting machine. The quality of the fiber laser directly affects the cutting performance and cutting quality of the metal cutter. Currently, well-known fiber lasers include German IPG lasers and China MAX lasers. Compared with other brands of lasers, both have the characteristics of high cutting quality, good stability, long service life and low maintenance cost.

Servo motor

The servo motor plays a role in controlling the operation of the original mechanical parts in the servo system. The high-quality servo motor can effectively ensure the cutting accuracy, positioning speed and repeat positioning accuracy of the laser cutter.

Control system

The control system is equivalent to the brain of the fiber laser cutting machine, controlling the machine tool to realize the movement of the X/Y/Z axis and controlling the output power of the laser.

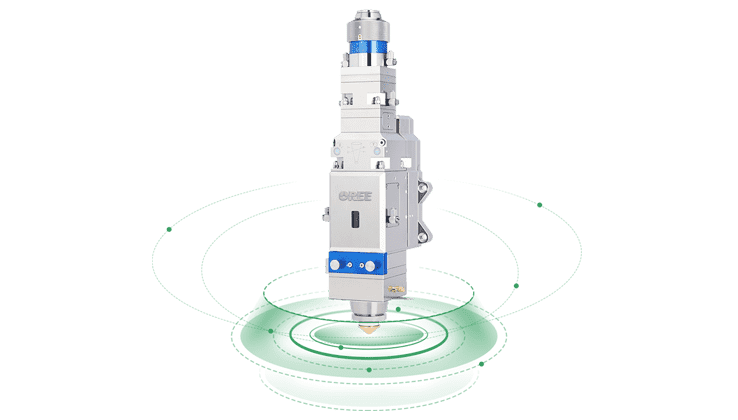

Laser head

The cutting head is the output device of the fiber laser cutting machine, which consists of a nozzle, a focus lens and a focus tracking system. Under the control of the control system and the movement of the machine tool, the nozzle moves along the cutting track to realize the cutting of metal materials.

For different materials and different thicknesses of metal, the height of the cutting head is different, so it is necessary to set the parameters through the control system to ensure effective cutting.

Laser lens

![]()

Laser lens occupies a very important position in the laser system, it will affect the power of the laser cutting machine. The laser lens can be selected according to the different requirements of cutting quality.

Professional Laser Cutting Machine Manufacturer - OreeLaser