09, 2019

by Oree Laser

Firstly, simply answer the question left in the last issue: The 8000w multi-module laser can consist of two 4000W single-module lasers or four 2000ws. Which of these two lasers is more advantageous?

The answer is: The multi-module laser with four 2000w is more advantageous, because the simpler the structure, the higher the reliability, the easier maintenance, and the more stable the system.

Are you right?

Today, OREE will give you some professional knowledge on carbon steel. A large number of experimental results show that when cutting stainless steel, aluminum, copper, The greater the power of the laser, the faster the cutting speed, the greater the cutting thickness. When cutting carbon steel, it is different from the situation described above. For example: 2000w and 12000w lasers have the same speed when cutting 6mm carbon steel. In fact, the laser cutting effect and speed of 2000w or more (including 2000w) are the same.The limit power is involved here, as mentioned below.

With the rapid development of fiber laser technology, the market demand for fiber laser cutting is getting higher. The bright surface cutting process of carbon steel is becoming more and more popular. There are two kinds of carbon steel cutting effects: (1) bright surface cutting; (2) abrasive surface cutting

What are the characteristics and advantages of bright surface cutting compared to abrasive surface cutting?

1.Smooth cutting surface

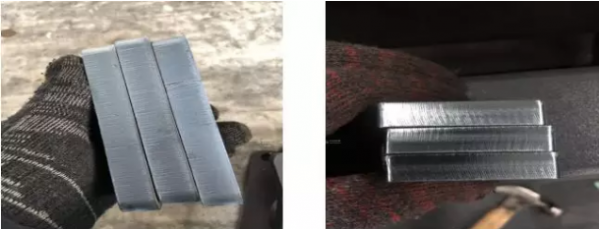

abrasive surface bright surface

2.Small taper, vertical cutting surface

abrasive surface bright surface

3.Fast speed

4.Suitable for cutting complex graphics

5.High precision

6.Higher power requirements

Cutting the same thickness of material, the bright surface cutting power is higher.

7.limit power

The higher the power within the limit power, the faster the speed and the better the cutting effect.

Under different limit power, what is the limit thickness they cut?

If you want to know the answer pls:Email oreelaser@gmail.com

WhatsApp+155 0869 2995,

You can get free consulting services from a professional manager.

Professional Laser Cutting Machine Manufacturer - OreeLaser