04, 2020

by Oree Laser

The application of robot flexible laser cutting in the automotive industry has become increasingly common, which is inextricably linked to the development of laser technology and the improvement of robot precise trajectory control technology. Under the new situation, the needs of car users are becoming diversified and personalized, and more and more new models are emerging. Most cars are gradually shrinking in batches, because some car manufacturers cannot predict and guarantee the future sales and stable output of a certain model, so they began to try low-cost robot laser flexible cutting equipment or production lines. This trend started in the automotive spare parts market and continued to expand and popularize in the fields of construction machinery, passenger cars, agricultural vehicles, electric vehicles and so on.

On the one hand, laser cutting often requires high position accuracy, and has high requirements on the accuracy of small trajectories such as small circles; On the other hand, it depends on the efficiency of the robot. In general, the speed of joint motion control of each axis of the robot is relatively slow, and the weight of the robot arm is too large to be suitable for high-speed movement; The third aspect is the rigidity of the robot. Robots with poor rigidity have severe jitter, poor robot tracking, and severe deformation of the robot, which cannot accurately reach the precise position to be cut in the digital model of the workpiece.

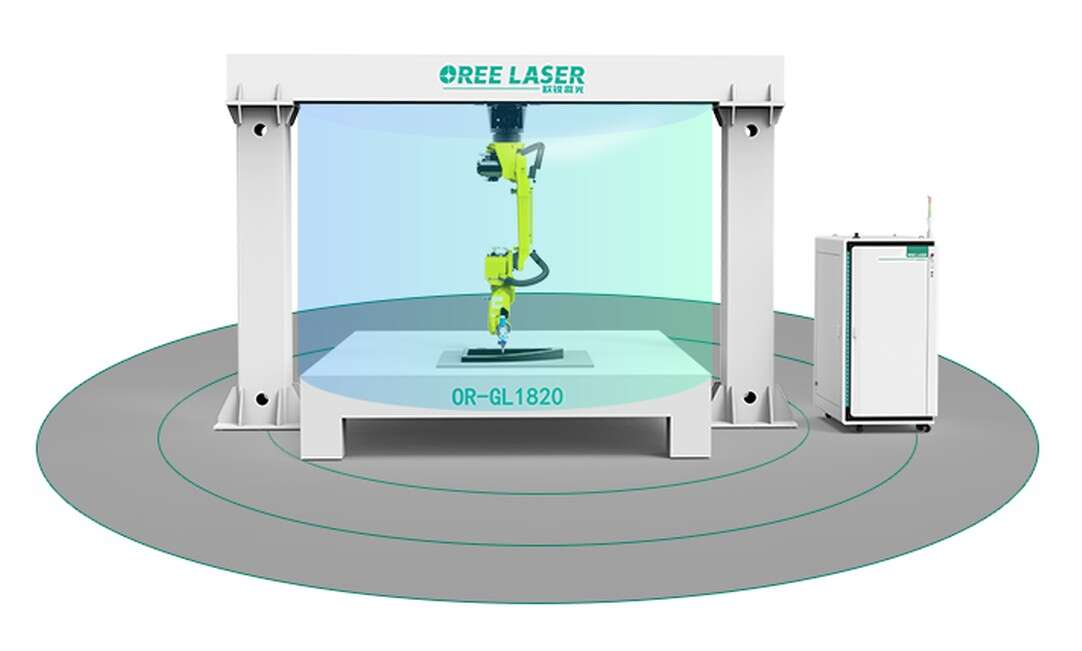

▲ 3D Robot Fiber Laser Cutting Machine OR-GL

● Working Plane

Oree three-dimensional robot GL series fiber laser cutting machine, equipped with large-size robot wide format, the maximum working radius can reach 1800mm. Common automotive sheet metal parts can be operated within the range of OR-GL robot workbench, and some large parts can also be realized through a mobile platform.

● Mechanical Arm

OR-GL is equipped with FANUC high-rigidity arms, light weight and good rigidity, at the same time, it can freely and flexibly realize a variety of complex three-dimensional curve processing trajectories, has good adaptability to complex curved surfaces, and is very suitable for robot flexible processing needs.

In addition to the rigidity difference of robot mechanical accuracy, the most important difference is the error of mechanical transmission, and the error of mechanical transmission is mainly reflected in the reducer. Oree 3D robot GL series fiber laser cutting machine adopts FANUC high-rigidity mechanical arm imported from Japan, equipped with advanced servo technology, which has good acceleration and deceleration performance, high precision, fast moving speed, repeated positioning accuracy of 0.03mm, saving processing time, improve production efficiency.

Professional Laser Cutting Machine Manufacturer - OreeLaser