Cookies

We use cookies to enhance your browsing experience, serve personalized ads or content. By clicking "

Accept cookies ", you consent to our use of cookies.

Further information on cookies can be found in our

Privacy Policy.

|

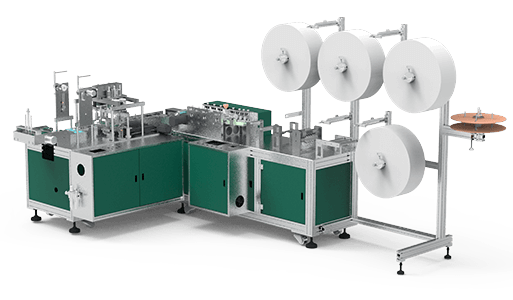

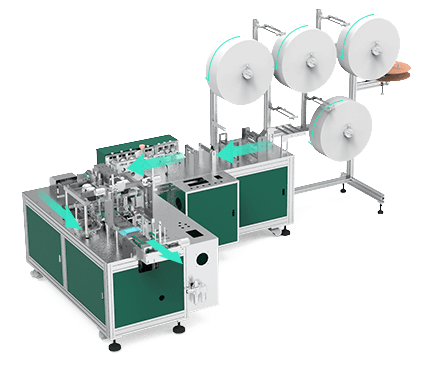

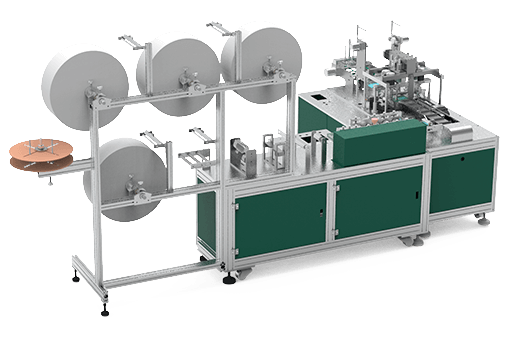

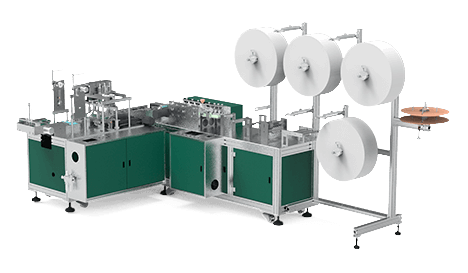

Model

|

OYD-PM200107001GS |

|

Equipment size

|

5000*2500*1500mm |

|

Weight

|

800kg |

|

Ultrasonic frequency

|

20KHz |

|

Air consumption

|

6-8kg/cm² |

|

Production capacity

|

80-85 pcs/min |

|

Model

|

OYD-PM200107001GS |

|

Equipment size

|

197*98*60inch |

|

Weight

|

800kg |

|

Ultrasonic frequency

|

20KHz |

|

Air consumption

|

6-8kg/cm² |

|

Production capacity

|

80-85 pcs/min |