09, 2018

by Site Editor

The world’s long-awaited 2018 FIFA World Cup finally opened. On June14th, the snow-capped city of Russia was mad, and the opening game was also started at the Luzhniki Stadium in Moscow. The World Cup was in full swing. The major media headlines are full of "World Cup" themes. In the four-year World Cup, the world's largest "football feast" not only made fans excited, but also made the beer market usher in a climax. It's really vivid to use "lovers" to describe the relationship between beer and the World Cup. Looking around the world, whether it is at home, in the streets, in front of the square screen, or in bars, KTVs, or any other place where you can see the World Cup football match, and beer is an essential “equipment” for enthusiastic fans.

When fans are drinking beer, they are cheering for their favorite team. Perhaps few people notice the bottle's label details. In fact, at this time, the laser is on your side. Beer is a favorite drink for people in the summer. It was introduced to China in the early 20th century. The source of the name was English Beer and was translated into Chinese “beer”, so it was called “beer”. Beer is generally packaged in glass bottles and iron bottle caps. The origin of laser marking technology and beer is that laser marking can perfectly mark beer bottle caps. The specific information is introduced by Oree laser.

Due to the production environment of the beer is relatively humid, and the bottle may oscillate during processing, so the processing requirements are relatively high. Bottle caps of beer bottles need to mark information such as production date, production lot number, etc. Traditional marks have not met the requirements of beer production marking. Laser marking technology combined with the application of automation has gradually replaced traditional mark technology in bottle wines with excellent performance on industry application. The laser marking machine is focused on the surface of beer glass bottle and cap with high-energy laser beam. Under the high energy of laser, the surface layer is physically vaporized in a very short time, leaving a smooth texture on the surface with a mark pattern. At the same time, the effective displacement of the laser beam can also be controlled, and the fine pattern text can be marked on the surface of the beer bottle.

With the further improvement of the food safety requirements of the country, the marking on food packaging is increasingly important. In particular, for alcoholic beverage products, liquor companies have a strong demand for anti-counterfeiting, anti-counterfeiting, and traceability. At this time. Laser marking technology has become the first choice for wine makers. Beer bottle caps, bottle body security code, production date, production batch number, brand LOGO and other information, which can be achieved by the laser marking technology.

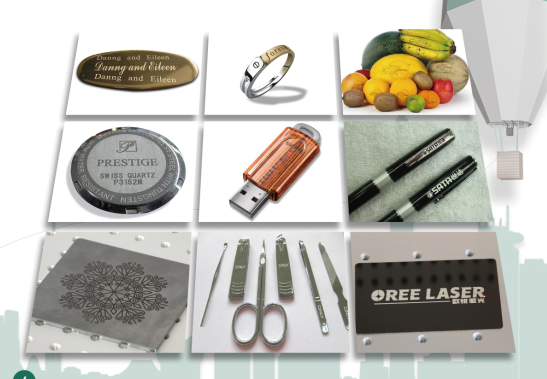

Laser marking is the most advanced technology for marking industrial products in the world. It has become an effective marking processing method. Lasers have good monochromaticity, coherence and directionality, and they can accumulate in a very small area with the high energy density, especially for material processing. Laser marking is a marking method that uses a high-energy-density laser to locally irradiate the workpiece to vaporize or change the color of the surface material, leaving a permanent mark. With the continuous upgrading and improvement of laser marking technology, the life and performance of laser marking machines have been greatly improved. Oree Laser with the advantages of clear marks, a wide range of applications, and low maintenance costs will become increasingly widespread in the beer industry. Let's go into laser marking together with the Oree laser marking machine.

OREE LASER has 15 years of experience in the laser industry. The annual production capacity of factory light marking machines is over 2,000 units, and the power is 20W, 30W, 500W, 100W. The machine is cost-effective, mainly used in electronic components, integrated circuits (ICs), electrical appliances, mobile phone communications, hardware products, tool accessories, precision instruments, eyeglasses and clocks, jewelry, auto parts, plastic buttons, building materials, PVC pipe and other materials. Oree has a modern enterprise technology center and top scientific research team, leading the laser technology developed. Their products has been exported to more than 80 countries and regions in Asia, Europe, Africa, America and Oceania. Committed to providing global users with comprehensive laser marking solutions to help customers improve economic efficiency.The laser marking machine has the following supporting systems:

I. Focusing system

The role of the focusing system is to focus the parallel laser beam at a point. The marking effect and range is changed from the different f-θ lens focal length. Fiber laser marking machine selection of imported high-performance focusing system, the standard configuration of the lens focal length f = 160mm, effective scanning Range Φ110mm. Users can choose the type of lens according to the need

II. Gold pull type

The entire device model architecture

III. Computer control system

Computer control system is the center of the whole laser marking machine control and command, and it is also the carrier of software installation. It is completed to the workpiece through the coordinated control of the acousto-optic modulation system and galvanometer scanning system.

IV.Laser power supply

Laser power of the laser marking machine is a device that provides power for the laser. Its input voltage is AC220V AC and installed in the marking machine control box.

V.Laser

This is the core part of the laser marking machine. According to the different models, it usually has many series of lasers, including optical fiber, ultraviolet, CO2, YAG, and semiconductor. Its output laser mode has a long service life and is designed to be installed in the marking machine housing.

VI.Galvanometer field scanning system

The galvanometric scanning system is composed of two parts: an optical scanner and servo control. Vibration lens is composed with three parts: stator, rotor and detection sensor. The entire system is designed and manufactured with new technologies, new materials, new processes, and new working principles.

The optical scanner adopts a servo motor with a moving magnetic deflection working mode. The optical scanner is divided into an X-direction scanning system and a Y-direction scanning system, and a laser reflection lens is fixed on each servo motor shaft. Each servo motor is digitally controlled by a computer to control its scanning trajectory

VII.Marking control software

Laser marking machine software is used to control the marking parameters, control the debugging of the application interface, and to operate all marking actions.

Laser marking machine principle

The laser marking machine mainly consists of four parts: laser power supply, laser, two coordinate worktables and numerical control system. The numerical control system controls the worktable to move according to the user's input program and marking process parameters. When a certain character or pattern is reached, a laser marking machine command is issued. After receiving the command, the laser emits a pulsed laser beam, and the laser beam is focused on the surface of the workpiece through the optical reflector group. Under the action of a powerful laser, the surface of the object is melted or evaporated to form traces. The combination of these dots is the word or pattern to be scribed

The type of laser marking machine and its application

Handheld laser marking machine R-H Technological appearance, reliable quality.

Hand-held marking machine has a unique design, with a small size, easy to carry, can be hand-held marking, convenient and quick.The fasteners are beautifully designed and durable. With high-speed galvanometer, faster. The laser head moves autonomously, can be separated, portable, and manually implement focal length control

The laser head can leave the body to move autonomously, and the focus can be marked by manual adjustment. Air cooling system, unique air cooling system, no water cooler, and reduced energy consumption

Profective fiber marking machine R-P full protection, auto focus

The marking machine is designed with fist protection level, and is first realized with the autofocus function by independent research and development. Intelligent automatic detection of thickness and automatic calibration can be performed without manual operation. Automatically adjust the focal length, small size, easy to carry. No consumables, more flexibility. The fasteners are beautifully designed and durable. With the high-speed galvanometer, the speed is faster. The optical fiber protective glass can filter strong light and protect the eyes. It is the best choice for home users.

R-T desktop, open work platform

The fasteners are beautifully designed and durable. Equipped with an open working platform, suitable for various materials, forms of marking work and multiple workpiece processing. It is the best choice for industrial marking.

The main benefits of using laser marking technology are:

● The laser marking is clear and eye-catching, which can't be erased permanently, and can prevent beer bottle body information from being altered in circulation.

● The laser marking technology is non-consumable and non-polluting, which can save a lot of operating costs for the company;

● Laser marking equipment can be automatically labeled with the production line to improve the company's production efficiency;

● The laser marking technology combined with QCTS quality safety electronic traceability management system can perfectly realize the full traceability of the product.

Seven Factors Affecting the Marking Quality of Laser Marking Machines

1. Laser beam energy and beam mode. In all laser processing, the first factor that should be considered is to select the appropriate laser beam energy and mode as the prerequisite for laser marking.

2. Focusing performance of the laser beam. Since the laser beam has a small focal point, the energy is very concentrated. Without good focusing performance, the ideal laser spot cannot be obtained, and the high energy density characteristics of the laser cannot be utilized, and the laser marking machine cannot be realized.

3.Workbench mechanical precision. The workbench is the mechanical part that drives the movement of the laser beam. Its accuracy directly affects the accuracy of laser marking.

4.Light path system. The light path system plays an important role in laser beam transmission. Its good work is also one of the preconditions of the laser marking machine.

5.The speed of the laser beam. During the interaction between the laser and the material, the speed of the laser beam is a very important parameter, which affects the effect of the laser and the material.

6.The characteristics of the material itself. Different materials interact with the laser to produce different effects. Different lasers and related parameters should be selected when using a laser marking machine.

7.Auxiliary equipment working conditions. Good auxiliary equipment can not only extend the useful life of the hardware, but also improve the effectiveness of laser marking

Oree laser marking machine advantages

Price & quality

Equipped with professional installation tools, organize regular assembly personnel to learn, continuously improve the assembly capabilities of software and hardware, strictly control supplier inventory, and use the best accessories, the most reasonable assembly process, to achieve the most efficient assembly efficiency. Reduce production costs, provide high-quality, low-cost high-quality laser cutting machine, so that customers get the best cost-effective products.

Warranty & service

36 months warranty, and provide guidance installation services, equipment testing or operation training services, maintenance services, equipment parts replacement services, problems and other requirements customers need to solve, regularly or irregularly provide customers with new product information services developed by the company.

Delivery

Strictly control the delivery, the standard machine will be produced in 7-10 days which is stably controlled, 15 days machine delivered (except customization).

Package

Laser equipment will do multiple protective measures during packaging, pearl wool, moisture-proof cloth, export wooden boxes, to ensure that each component will not be subject to collision and other injuries.

Transport

We are committed to providing global customers with comprehensive laser application solutions supporting maritime, air, land, and various customs clearance services.

OEM can be customized, and lighting up this world with green is the dream of Oree, and we are here looking forward to long-term cooperation with you

Process of production (assembly)

The higher precision of the machine makes the finished product more perfect and accurate. The gear of international high-end brand, no abnormal wear, can improve the service life of machine tool. The laser collimator can directly display the error of the machine installation precision. Check the gear meshing abnormal wear degree. High precision marble measurement is more suitable for the precision of three-axis mechanical installation.

Technical Design

According to the design requirements, the mechanical properties of the theory are calculated, and the main components of the finite element stress and motion analysis are formed. According to the finite element analysis, the parameter design of the parts can verify the operation performance of the machine for a long time from the design stage,

So as to meet the requirements of the machine tool performance in theory design.

QC quality control

The QC system runs through the whole production process, each part of the machine, small to one screw, OREE LASER will strictly control the quality control and eliminate any parts that do not meet the standard.

Professional Laser Cutting Machine Manufacturer - OreeLaser