02, 2021

by Oree Laser

What are the precautions for restarting the laser cutting machine when resuming work after a holiday?

How to turn on the laser cutting machine that has not been used for a long time? Oree Laser reminds you to check the following content and start the laser cutting machine carefully.

Preparation before testing

01 In order to ensure the safety of personnel and equipment, it is necessary to ensure that the total power supply of the laser system and the water cooler is disconnected, and live-work is strictly prohibited;

02 Close all inlet and outlet valves of the water cooler.

Reminder: Do not direct your eyes to the direction of laser emission at any time.

1.System inspection and maintenance

[1]power supply system

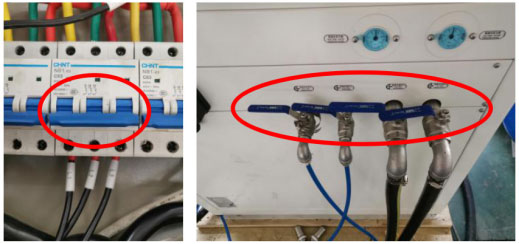

01 Power supply line: no serious bending, no damage, no disconnection;

02 Power cord connection: press the plug to make sure the connection is firm;

03 Control signal line: The interface is connected firmly without looseness.

[2]Gas supply system

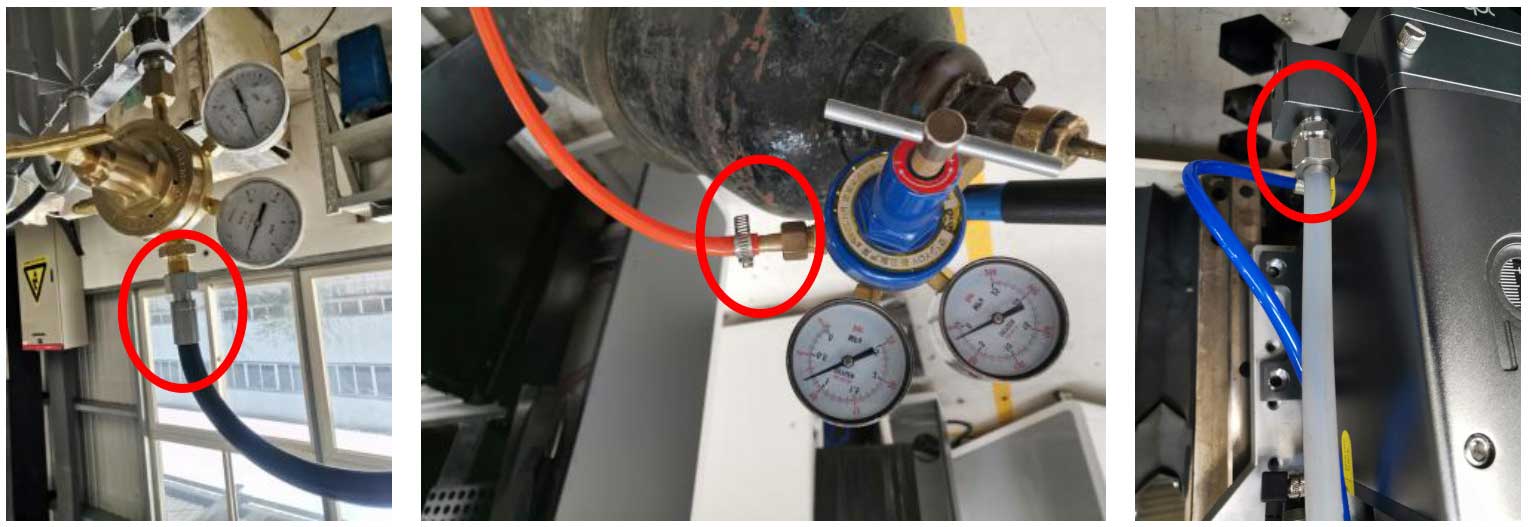

01 Air pipeline: no damage, no blockage, good airtightness;

02 Tighten the joints of each gas pipeline to ensure firm and unobstructed connections;

03 Use gas that meets the standard according to the requirements of the equipment manufacturer.

[3]Cooling system

01 Confirm again to close the water inlet and outlet valves;

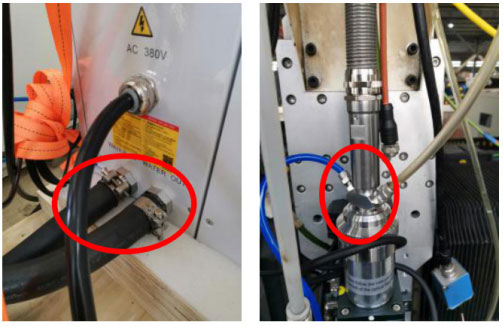

02 Water tank/pipe: no bend, no blockage, no damage, clean the water tank and pipe;

03 Tighten all water pipe joints to ensure firm and unobstructed connection;

04 If the local temperature is lower than 5°C, use warm air equipment to blow the internal pipes of the water cooler for a period of time to confirm that there is no freezing;

Reminder: If the equipment is shut down for a long time in an environment below 0℃, carefully check the cooling water pipe for signs of icing or ice. If you find any signs, please contact the equipment supplier in advance to avoid greater losses after the operation!

05 Pour the specified amount of distilled water into the water cooler and let it stand for 30 minutes to ensure that there is no sign of water leakage;

Reminder: If the temperature is lower than 5℃, it needs to be diluted and added with antifreeze according to the correct method.

06 Turn on the power switch of the water cooler, and keep the power of other equipment off;

07 Open the water inlet and outlet valves of the water cooler a small amount, run the water cooler, make the cooling water circulate from the laser and the optical head back to the water tank at a low flow rate, and drain the excess air in the water circuit pipeline. This process is recommended to be completed within 1 minute;

08 Mark the water level of the water tank and let it stand for another 30 minutes to observe whether the water level changes and again to ensure that there is no leakage in the internal pipeline;

09 When there is no problem with the above confirmation, restart the water chiller and open the water valve normally, and wait for the water temperature to reach the set temperature to prepare for the operation of the equipment.

Equipment operation test

[1] Preparation before the equipment is powered on

01 Confirm that the water temperature of the water chiller has reached the set temperature;

02 Turn on the power switch of the laser processing system. After the laser is powered on, the POWER indicator on the laser panel will light up.

Reminder: first check the optical circuit, do not directly emit light or process it, after the laser is started, observe whether the indicators are normal and whether there is an alarm. If an alarm is detected, you can connect to the laser monitoring software to view the alarm information, and contact the equipment supplier!

[2] Detection before light emission

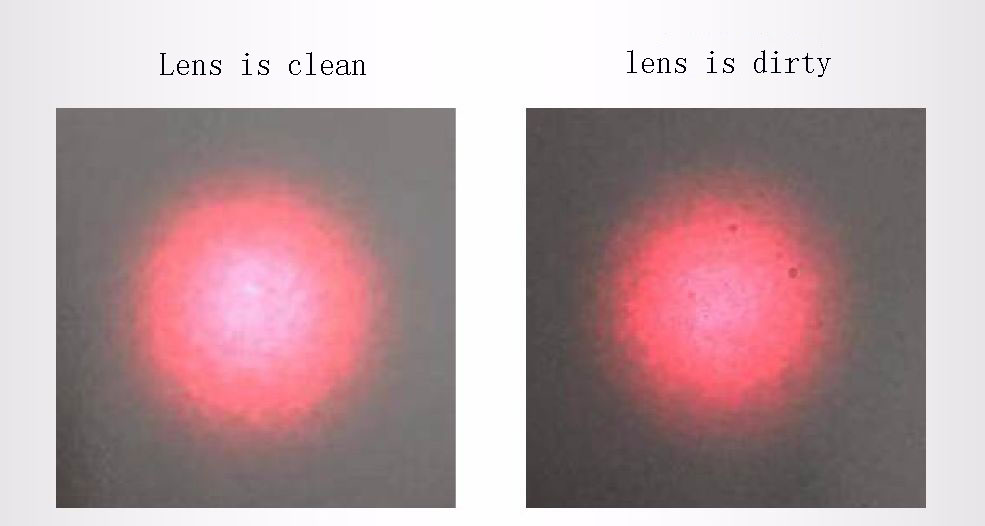

01 Use red light detection method to check lens cleanliness, methods as below:

Nozzle: single layer nozzle size above 2.0mm;

Tools: Blank paper;

Detection method:

1. The MAX laser configured in the Oree fiber laser cutting machine has a red light indicator when it is turned on;

2. The white paper is about 300mm away from the nozzle of the cutting head to see the red light;

3. If there are obvious black spots or irregular black objects in the red light, the lens is dirty and needs to be cleaned before cutting and debugging.

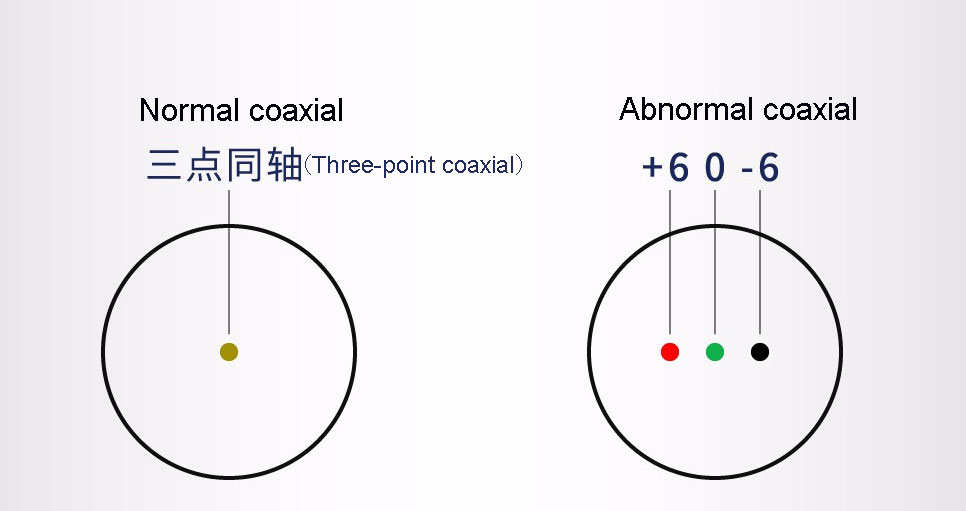

02 Coaxial test: judge the coaxiality between the nozzle outlet hole and the laser beam, methods as below:

Nozzle: size 1.2mm;

Tool: Scotch tape;

Scotch tape paper Method:

1. Adjust the coaxial at focal point 0 so that the laser is at the center of the nozzle;

2. Dot the light at the focal point of ±6mm;

3. If the focus 0 and ±6mm light spot are both in the center of the nozzle, it is normal; otherwise, replace the cutting head or the laser light path is offset.

When you complete the above inspection, the laser cutting machine can process the light normally~

Professional Laser Cutting Machine Manufacturer - OreeLaser