03, 2020

by Oree Laser

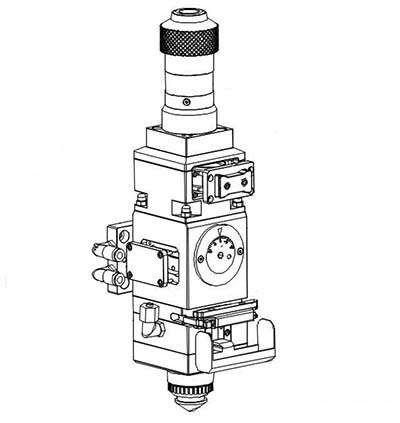

As we all know, one of the most important components of a fiber laser cutting machine is a laser cutting head, which has the characteristics of high accuracy and high price. The length of the life of the laser cutting head not only affects the operating efficiency of the fiber laser cutter, but also relates to the production costs and benefits of the factory. The most important factor affecting the life of the cutting head is the contamination and damage of the optical lens.

The optical module inside the cutting head includes: a collimation module (including a collimator lens), a focusing module (including a focusing lens), and a protective mirror window box (including a protective lens).

Maintenance of the laser cutting head

The causes of lens contamination are:

1. The fiber head installation method in the cutting head is incorrect

2. The sealing effect of the cutting head itself is poor

3. Incorrectly replace the protective window box

4. Use of unreasonable cutting head wearing parts

5. Improper operation of laser cutting machine

6. Poor maintenance of the cutting head

7. Incorrect selection of laser cutting process data parameters

Although there is no guarantee that the cutting head will never be contaminated, proper precautions can slow down lens aging and minimize lens wear.

Oreelaser proposes the corresponding solution for you:

1. To choose the correct fiber head installation method. Most installers tend to arbitrarily assemble the cutting head, tilting the installation direction of the optical fiber head, resulting in careless installation. We should try to keep the fiber head horizontal during the installation process, install it inside the cutting head and lock it.In addition, during the installation process, it is necessary to avoid dust, and try to operate in a clean environment to prevent dust from entering the laser head.

2. As for the sealing of the cutting head, even if it is produced according to German technology, it may not be able to guarantee complete sealing. And in the later operation process, due to the constant temperature difference between the cutting head (relatively at a high temperature) and the outside world (relatively at a low temperature), unbalanced air pressure will cause dust to enter the cutting head and affect its life.Then, a feasible method is to install a breathing system to maintain a stable air pressure inside the cutting head.

3. Due to the relatively large size of the protective lens case, particles are inevitably mixed in during the replacement process. Therefore, when replacing the protective lens case, the speed must be fast, and when the lens case is quickly pulled out, the window is sealed with tape or other films, and the replacement is done carefully.

4. Select a qualified protective lens and "O" -shaped sealing rubber ring to ensure the sealing of the cutting head to the greatest extent and prevent the ingress of dust particles.

5. When operating a laser cutting machine, be sure to strictly follow the equipment instructions and requirements for correct operation. Reduce the impact of improper operation on the cutting head.

6. The cutting head should be kept as clean and dry as possible, and cleaned regularly.

7. The laser cutting process can be divided into four types: vaporization cutting, melting cutting, oxidative melting cutting, and controlled fracture cutting. Because the parameters corresponding to different cutting processes include cutting power, type of cut sheet, thickness of cut sheet, selection of auxiliary gas and other parameters, careful selection of the cutting process can protect the laser cutting head.

Professional Laser Cutting Machine Manufacturer - OreeLaser