03, 2019

by oreelaser

Fiber lasers are the core components of the fiber laser cutter and it have a large impact on the cutting performance of laser cutting machines. When choosing a laser cutting machine, what is the module integration method that needs to consider fiber lasers?

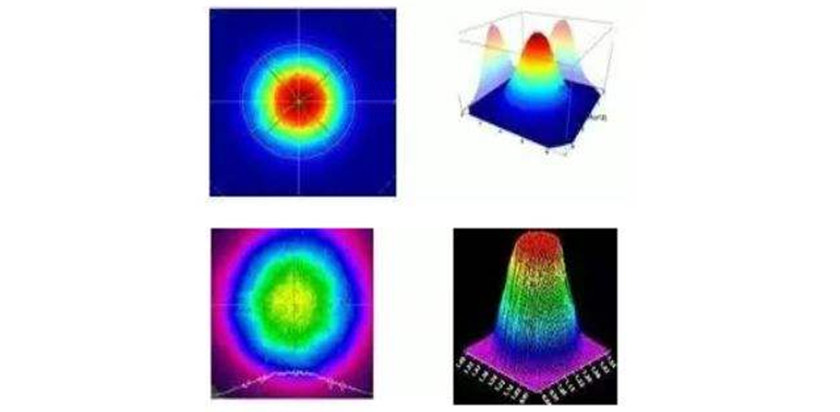

The module composition of the fiber laser is divided into single mode and multimode. In the cutting application, the focused spot has a great influence on the quality of the cut. The core of the single mode laser is relatively thin, and the beam quality is better than the multimode. Its energy distribution is Gaussian with the highest energy density in the middle, and the three-dimensional map is a sharp mountain peak.

The core of a multimode laser is coarser than a single mode. The energy distribution is smaller than that of a single mode. The three-dimensional image is an average of a single-mode spot. The three-dimensional image is an inverted cup. In terms of the steepness of the edge, the multimode is much steeper than the single mode.

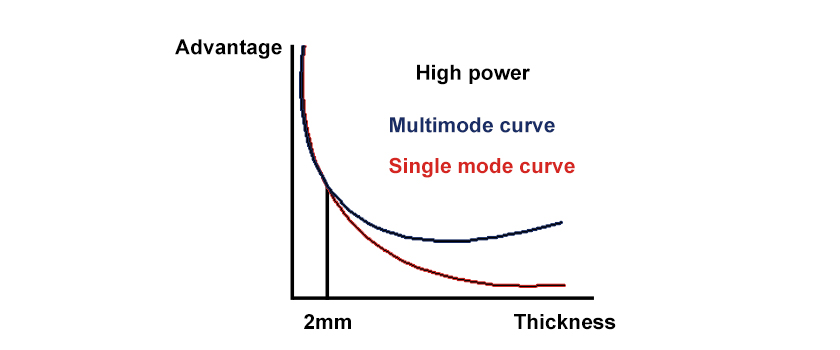

1mm thin plate cutting speed of single mode laser is 20% higher than multimode laser, the visual effect is similar. However, starting from 2mm, the speed advantage is gradually reduced. Starting from 3mm, the speed and effect of high power multimode laser are very obvious. As shown below:

Therefore, the advantage of single mode is suitable for thin plate, and the advantage of multimode is thick plate. Therefore, single mode and multimode are not compared with each other. They are all a configuration of fiber laser. It is like a car. The car is suitable for highway and sports car is suitable for mountain. However, the car can also run the mountain, the sports car can also run the road. So the choice of multi-mode or single-mode fiber laser depends on the actual end-user processing needs.

Single mode and multi mode, how to choose?

From the perspective of power level, the laser of 1000W or less is mainly due to its low energy, and the thickness of the main processing material is biased toward the thin plate.

Therefore, the single-mode configuration of the laser within 1KW is in line with the actual market conditions, and the laser with a power of 1KW or more should be thin and thick. From the perspective of the entire processing industry, the improvement of processing quality is a rigid requirement and cannot be compromised. Therefore, many high-power lasers will not consider single-mode, and the processing quality must be the first.

At the same time, the single-mode core is generally thin, meaning that the same power laser is transmitted in it, and the single-mode core has a larger optical energy load, which is a test for materials. At the same time, when cutting high-reflection materials, the high-intensity reflected light and the emitted laser are superimposed. If the tolerance of the fiber material is insufficient, it will be very easy to "burn the core", and it is also a challenge to the life of the core material. Therefore, many laser manufacturers still use multi-mode configurations in the configuration of high-power fiber lasers.

Professional Laser Cutting Machine Manufacturer - OreeLaser