10, 2019

by Oree Laser

Laser welding is one of the important aspects of the application of laser material processing technology. In the 1970s, it was mainly used for welding thin-walled materials and low-speed welding. The welding process is heat-conducting. That is, laser radiation heats the surface of the workpiece and surface heat is diffused internally by heat conduction. By control, the parameters such as the width, energy, peak power and repetition frequency of the laser pulse, the workpiece are melted to form a specific molten pool. Due to its unique advantages, it has been successfully applied to precision welding of a small part. The emergence of high-power CO2 and high-power YAG lasers has opened up a new field of laser welding. Deep-fusion welding based on a small hole effect has been widely used in the industrial files of machinery, automobiles, and steel.

Compared with other welding techniques, laser welding has the following advantages:

● Fast speed, large depth, and small deformation.

● It can weld refractory materials such as titanium, quartz,tec., and can weld the opposite material, and the effect is good.

● Micro soldering is available. The laser beam is focus to obtain a small spot, and can be accurately positioned, and can be applied to the mass welding of small workpieces that are automatically produced in large quantities.

● It can weld at home temperature or under special conditions, and the welding equipment is simple. For example, the laser passes through an electromagnetic field, and the beam of light does not shift; Laser can be welded in a vacuum, air, and some gas environment, and can be welded through glass or transparent materials of beam.

● After laser focusing, the power density is high. When using high-power devices, the ratio of depth to width can reach 5:1 and the maximum can reach 10:1.

● The laser beam is easy to split light according to time and space and can perform multi-beam simultaneous processing and multi-station processing.

● It can weld non-accessible parts and perform non-contact long-distance welding with great flexibility. Especially in recent years, the optical fiber transmission technology has been adopted in the YAG laser processing technology, which has made laser welding technology more widely popularized and applied.

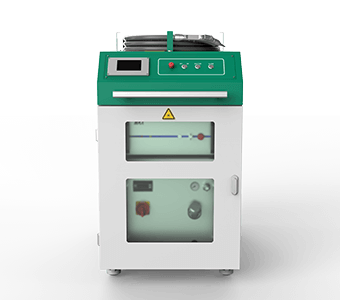

OREE laser hand-held fiber laser welding machine adopts the latest generation of fiber laser and is equipped with an intelligent laser welding head. It has many advantages such as simple operation, beautiful welding line, fast welding speed, and no consumables. Welding applications in metal materials such as thin stainless steel plates, carbon steel plates, and galvanized sheets can perfectly replace traditional argon arc welding and electric welding. Hand-held laser welding machine can be widely used in kitchen cabinets, stair elevators, shelves, ovens, stainless steel door, and window guardrails, distribution boxes, stainless steel home, and other industries.

Professional Laser Cutting Machine Manufacturer - OreeLaser